Robot design-non-standard mechanical design

2023.02.09

At present, there are many types of robotics in manufacturing. There is no unified statement about the standards of classification in China, but the classification is as follows according to its way of use and driving methods:

1. Classified by usage

The robot can be divided into dedicated robots and universal robots

1. Dedicated robotic hand

It is a mechanical device with a host, a fixed program without an independent control system. Dedicated robotics have the characteristics of small movements, single work objects, simple structure, reliable use and low cost, etc., and are suitable for large quantities of automated production, such as automatic machine tools, automatic lines, feeding robots, and automatic automatic automatic automatic automatic automatic Change the knife robot.

2. GM robot

It is an independent control system, a variable program, and flexible action. Within the range of specifications, its action program is variable. It can be used on different occasions by adjustment. The driving system and control system are independent. GM robotics have a large scope, high positioning accuracy, and strong generality. It is suitable for small and medium -sized automation production that constantly changes production varieties. GM robots can be divided into two types: simple and servo -type: simple type control positioning in the way of control positioning. Points can also achieve continuous trajectory control. Generally, the general servo -type universal robot is a CNC type.

2.Divide according to the driver

1. Hydraulic transmission robot

It is a robotics that drives the execution of the institutional movement with hydraulic pressure. Its main feature is that the weight can reach more than hundreds of kilograms, the transmission is stable, the structure is compact, and the action is sensitive. However, the requirements for sealing devices are strict, otherwise the leakage of oil has a great impact on the working performance of the robot, and it should not work at high temperature and low temperature. If the robot uses an electro -hydraulic servo driver system, continuous trajectory control can be achieved, so that the universality of the robot can be enlarged.

2. Pneumatic drive robotic hand

It is a manipulator that drives the pressure of the institution to compress the air. Its main characteristics are: extremely convenient use, small output force, rapid pneumatic movement, simple structure, low cost. However, because the air has the characteristics of compressed, the stability of the work speed is poor, the impact is large, and the pressure of the gas source is low. The weight is generally less than 30 kg. It is larger than the hydraulic robotic structure under the same weight. Therefore, it is suitable for work in high -speed, light load, high temperature and dust environment.

For example, the use of rodless cylinders makes this type of robotic player has great similarity with mechanical transmission robotics in terms of structural treatment. The difference is that this type of robotic player can only achieve two points of position control, and grasp the grasp Gravity is small.

3. Mechanical transmission robot

That is, a robot driven by a mechanical transmission mechanism (such as cam, connecting rods, gears and racks, straight wire guide rails, screws, etc.). It is a dedicated robot affiliated to the work host, and its power is transmitted by work machinery. Its main feature is that the exercise is accurate and reliable, the frequency of action is large, but the structure is large, and the action program is unchanged. It is often used for the upper and lower feeding of the host.

This type of robotic player is currently the most widely used one. The following two major categories we use according to the specific characteristics of use:

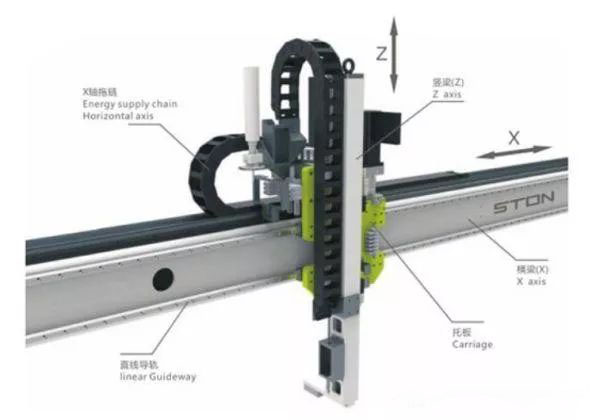

(1)The combination of gears, ranges plus straight wire guide.

-

That is, a special structure with a special structure, a straight -wire motor or a power step motor that directly drives the execution mechanism of the mechanism. Because the intermediate conversion mechanism is not required, the mechanical structure is simple. Among them, the straight -wire motor robot has a fast speed and long itinerary, and it is convenient for maintenance and use. There are not many such robots, but there are future development.

Personally, I use and design the most special mechanical transmission robot, that is, the robotic hand used by using the gear, tooth strips, and straight -line guide rails with CNC processing machine tools. Introduce it in detail in subsequent articles.

(2)Linear module combination

(2)Linear module combination

4. Electric transmission robotics

Previous:Introduction of worm wheel processing method and problem of rolling adjustment

Next:CNC processing process interruption/or cutting knife delete procedure skills

Related Information

- Industry news

- The tap or drill bit breaks in the hole, how to fix it?

- Why do airplanes use rivets instead of welding?

- Why are engineering drawings all blueprints?

- How is a ping pong ball made? It turns out that it is made of two pieces of plas

- What to do if quality is abnormal? Doing these 3 things well is the key!

- Weekly News 9.7-9.13

- Huawei's three-fold screen is approaching, and the domestic supply chain is wait

- Innovative application of digital twin technology in integrated die-casting prod

- 5 types of carbide cutting tools, what are the differences? Save this article an

- Global manufacturing PMI in June was 49.5% | Weekly News 7.6-7.12

- Raw material defects | Machining special operations and practical cases 109

- No wonder Toyota stamping is so good: a day in the life of a Toyota stamping sho

- Analysis on the development trend and demand of China's mold industry

- How many types of sealing rings are there in machinery? What are they used for?

- Hangfa, Hangfa, a scar on the hearts of machine processing workers

- How to mill a large arc surface with a small cutter?

- Dynamics of the processing center of the process! What is the fundamental reason

- 500 ° C ultra -strong aluminum alloy! This problem is overcome

- How much do you know about the hometown of machine tools and molds, how much do

BACK

BACK MT HOME

MT HOME Navbar

Navbar