Hangfa, Hangfa, a scar on the hearts of machine processing workers

2024.06.07

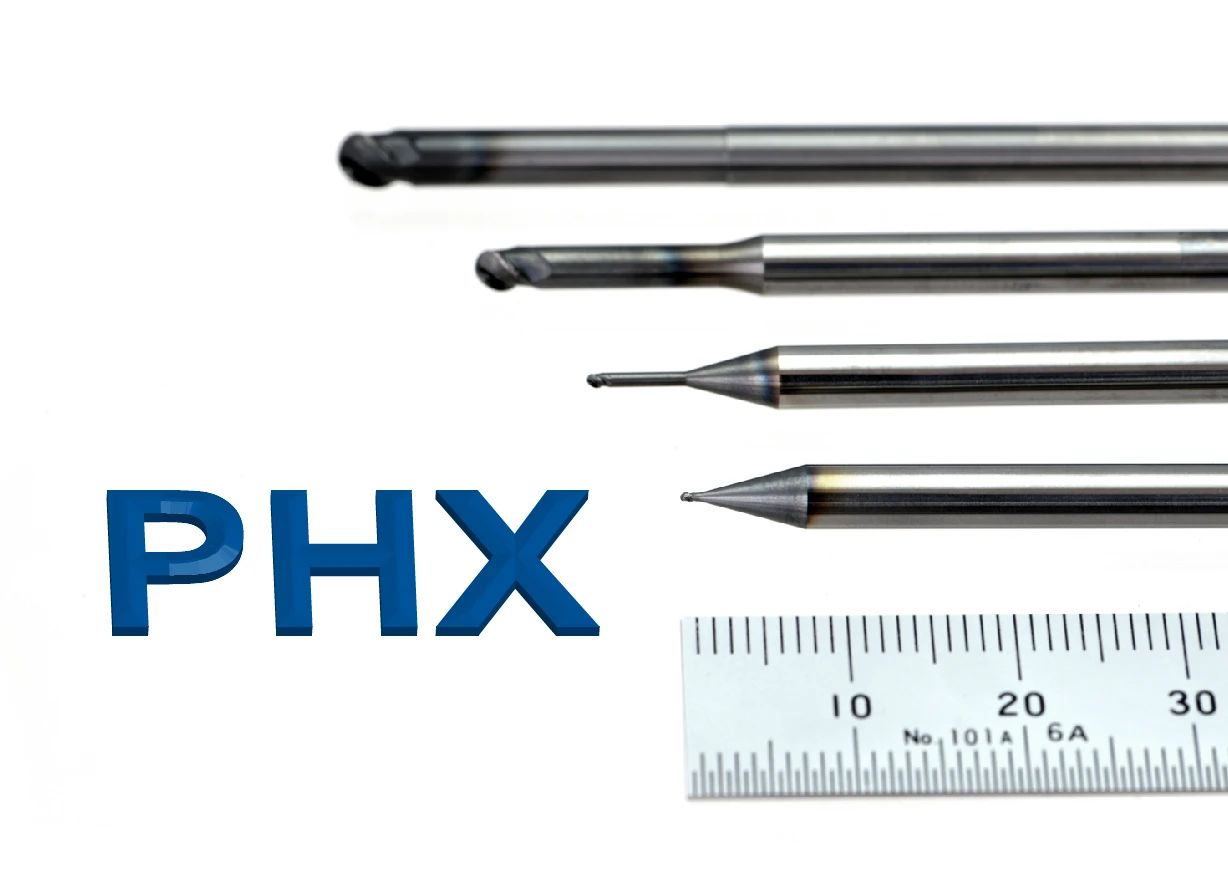

OSG PHX Series Milling Cutter

Introduction to processing technology and solutions

Improve the problems of reduced tool life and poor machined surface caused by cutting heat when processing nickel-based heat-resistant alloys.

Difficulties in workpiece processing

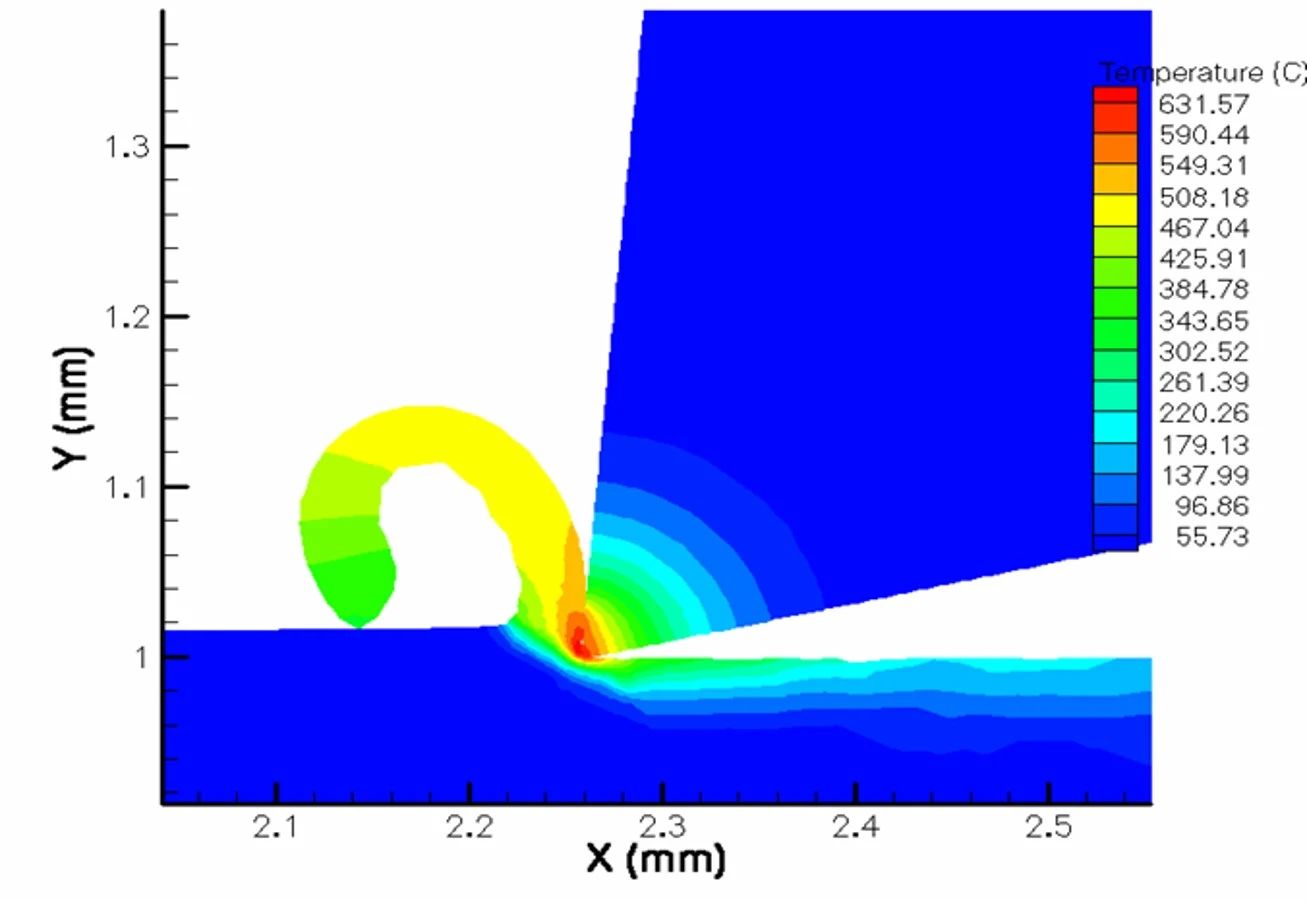

From the figure, we can see that the cutting heat is mainly concentrated at the cutting point. In other words, if the heat of the cut iron chips is low, most of the heat will remain on the surface of the material, which will increase the heat of the tool during continuous processing, resulting in a reduction in the life of the tool and burrs on the processed surface.

Processing method

Using a tool with a special blade shape, the generated chip shape is easy to absorb cutting heat, and the heat is taken out with the chips during the processing process. Here we use OSG's high-rigidity tool PHX series.

Processing example and conclusion

Processing material: nickel-based heat-resistant alloy

Tool overhang: 8D

Cutting distance: 660m

Incision: ap=0.3mm ae=0.6mm

Cutting speed: 120m/min (6366min-1)

Feed speed: 1900mm/min (0.1mm/t)

Processing time: 6h

Processing result: normal wear, no dissolution

Wear after 6 hours of machining

Tool advantages and effects

OSG PHX series milling cutters use special blade shapes to make the chips long and thin, and concentrate the cutting heat on the discharged iron chips, so that the heat of the machining surface and the tool itself can be controlled during the machining process, thereby greatly improving the tool life and machining surface accuracy.

02 Zhengzuan-Sintered PCD Twist Drill

In traditional drilling processing, carbide tools are generally used. However, the surface quality of the hole wall, the problem of exit burrs and the life of the tool are always the key aspects that need to be paid attention to in the research and development of tool products.

Product advantages

Compared with traditional coated tools, even under higher cutting parameters, not only the process is more reliable, but also the blade life is longer;

Adopting advanced PCD sintering technology to achieve high process reliability and stability;

There are almost no breaks and burrs at the exit of the processed hole, and the surface quality of the hole wall is good;

For composite processing, minimize the risk of delamination;

The full range of product standardization + modular solutions can be delivered quickly.

Processing method

Zheng Zuan adopts advanced PCD sintering technology to achieve a high degree of process reliability and stability. The integral PCD drill bit with spiral breaks through the design limit, carries out process innovation of drill bit products, and successfully develops the DT33Z series and DT34Z series of sintered PCD twists. Drill.

The new drill bit not only significantly improves the surface quality of the hole wall and reduces the generation of exit burrs, but also greatly extends the service life of the tool, bringing revolutionary improvements to drilling processing.

Scope of application

Applicable to different grades of aluminum alloys and CFRP/GFRP materials, and can be used for abrasive materials in the automotive, civil aviation and composite material processing industries to meet the high quality requirements for drilling.

For inquiry and quotation of CNC custom service, please contact :

Phone /Wechat/Whatsapp: +86 13612776575

E-mail:sales03@dgmtwj.cn

Previous:How many types of sealing rings are there in machinery? What are they used for?

Next:How to mill a large arc surface with a small cutter?

Related Information

- Industry news

- The tap or drill bit breaks in the hole, how to fix it?

- Why do airplanes use rivets instead of welding?

- Why are engineering drawings all blueprints?

- How is a ping pong ball made? It turns out that it is made of two pieces of plas

- What to do if quality is abnormal? Doing these 3 things well is the key!

- Weekly News 9.7-9.13

- Huawei's three-fold screen is approaching, and the domestic supply chain is wait

- Innovative application of digital twin technology in integrated die-casting prod

- 5 types of carbide cutting tools, what are the differences? Save this article an

- Global manufacturing PMI in June was 49.5% | Weekly News 7.6-7.12

- Raw material defects | Machining special operations and practical cases 109

- No wonder Toyota stamping is so good: a day in the life of a Toyota stamping sho

- Analysis on the development trend and demand of China's mold industry

- How many types of sealing rings are there in machinery? What are they used for?

- Hangfa, Hangfa, a scar on the hearts of machine processing workers

- How to mill a large arc surface with a small cutter?

- Dynamics of the processing center of the process! What is the fundamental reason

- 500 ° C ultra -strong aluminum alloy! This problem is overcome

- How much do you know about the hometown of machine tools and molds, how much do

BACK

BACK MT HOME

MT HOME Navbar

Navbar