How many types of sealing rings are there in machinery? What are they used for?

2024.06.13

Engineering machinery cannot do without oil cylinders, and oil cylinders cannot do without seals. The most common seal is the sealing ring, also called oil seal, which plays the role of isolating oil and preventing oil from overflowing or passing through. Here are some common types and forms of oil cylinder sealing rings for everyone.

Common sealing rings used for hydraulic oil cylinders are the following types: dust ring, piston rod sealing ring, buffer sealing ring, guide support ring, end cover sealing ring and piston sealing ring.

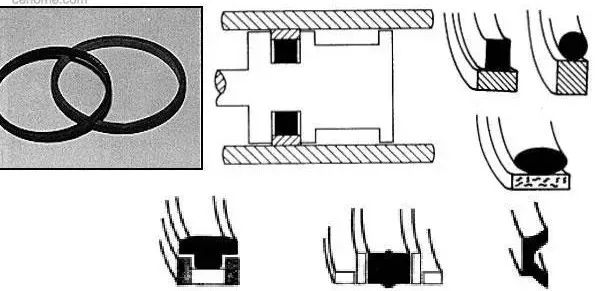

Dust seal

The dust seal is installed on the outside of the hydraulic cylinder end cover to prevent external pollutants from entering the cylinder. It can be divided into snap-in type and press-in type according to the installation method.

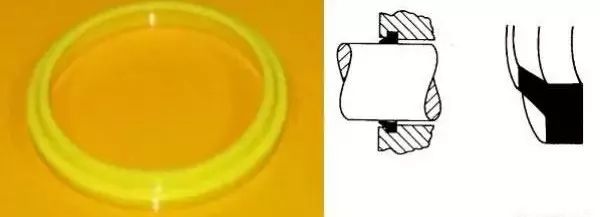

Basic forms of snap-in dust seals

Snap-in dust seals are the most common. As the name implies, the dust seal is stuck in the groove on the inner wall of the end cap and is used in less harsh environmental conditions. The material of the snap-in dust seal is usually polyurethane. There are many variations in the structure, such as the H and K-type sections with double lip structures, but the essence remains unchanged.

Some variations of snap-in wipers

Press-in wipers are used in harsh, heavy-duty conditions and are not stuck in a groove. Instead, they are made of polyurethane with a layer of metal wrapped around it for added strength and pressed into the cylinder end cap. Press-in wipers also come in a variety of forms, including single-lip and double-lip.

Piston rod seals

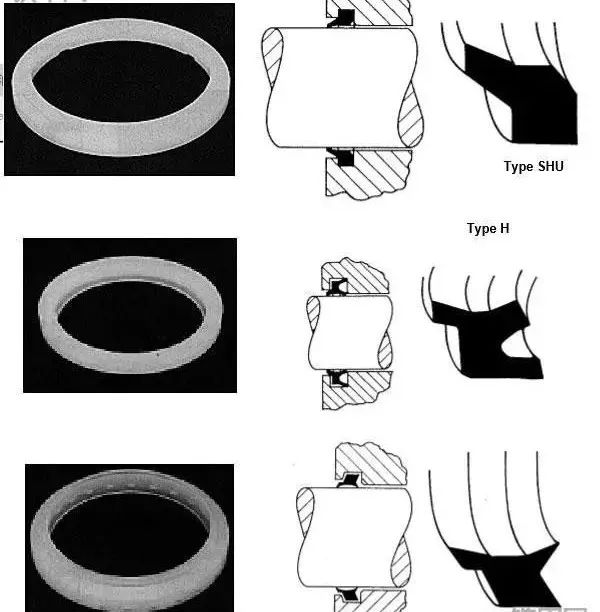

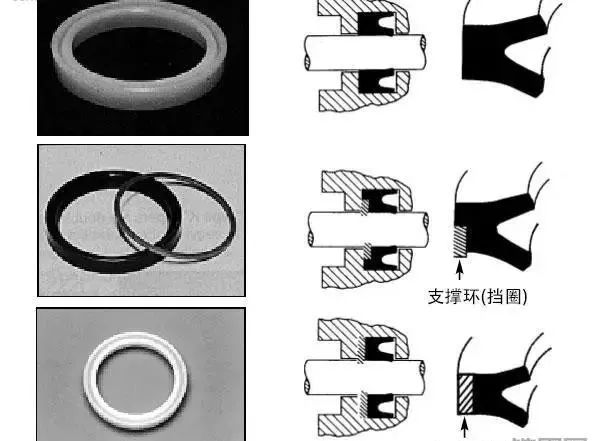

The piston rod seals, also known as U-cups, are the main piston rod seals and are installed on the inside of the hydraulic cylinder end cap to prevent hydraulic oil from leaking out. Piston rod seals are made of polyurethane or nitrile rubber and in some cases need to be used with support rings (also called retaining rings) to prevent the seals from being squeezed and deformed under pressure. There are also many variations of piston rod seals.

Common piston rod seal forms

Some variations of piston rod seals

Buffer seals

Buffer seals are used as auxiliary piston rod seals to protect the piston rod when the system pressure suddenly increases. There are three common types of buffer seals. Type A is a single-piece seal made of polyurethane. Types B and C are two-piece seals used to prevent seal extrusion and allow the seal to withstand higher pressures.

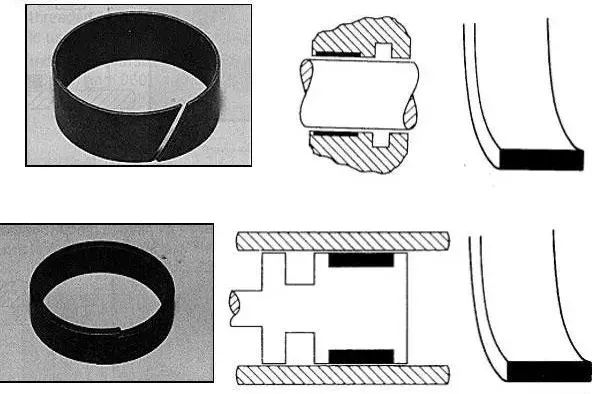

Guide support ring

The guide support ring is installed on the end cover and piston of the hydraulic cylinder to support the piston rod and piston, guide the piston to make linear motion, and prevent metal-to-metal contact. The materials include plastic, bronze coated with polytetrafluoroethylene, etc.

Used for guide support rings on hydraulic cylinder end cover and piston

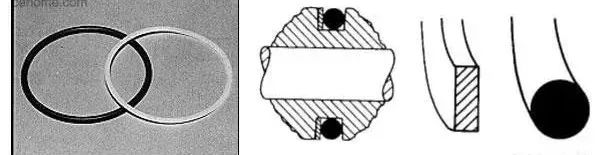

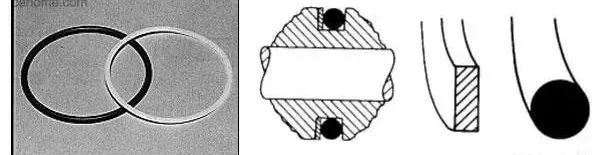

End cover seal ring

End cover seal ring is used to seal the end cover of the cylinder and the cylinder wall. It is a static seal used to prevent hydraulic oil from leaking from the gap between the end cover and the cylinder wall. It is usually composed of nitrile rubber O-ring and support ring (retaining ring).

Piston seals

Piston seals are used to separate the two chambers of the hydraulic cylinder and are the main seals in the hydraulic cylinder. They are usually two-piece, with the outer ring made of PTFE or nylon and the inner ring made of nitrile rubber. There are also many variations, including bronze coated with PTFE, etc. On single-acting cylinders, there are also polyurethane U-cups.

Several common forms of piston seals

For inquiry and quotation of CNC custom service, please contact :

Phone /Wechat/Whatsapp: +86 13612776575

E-mail:sales03@dgmtwj.cn

Previous:Analysis on the development trend and demand of China's mold industry

Next:Hangfa, Hangfa, a scar on the hearts of machine processing workers

Related Information

- Industry news

- The tap or drill bit breaks in the hole, how to fix it?

- Why do airplanes use rivets instead of welding?

- Why are engineering drawings all blueprints?

- How is a ping pong ball made? It turns out that it is made of two pieces of plas

- What to do if quality is abnormal? Doing these 3 things well is the key!

- Weekly News 9.7-9.13

- Huawei's three-fold screen is approaching, and the domestic supply chain is wait

- Innovative application of digital twin technology in integrated die-casting prod

- 5 types of carbide cutting tools, what are the differences? Save this article an

- Global manufacturing PMI in June was 49.5% | Weekly News 7.6-7.12

- Raw material defects | Machining special operations and practical cases 109

- No wonder Toyota stamping is so good: a day in the life of a Toyota stamping sho

- Analysis on the development trend and demand of China's mold industry

- How many types of sealing rings are there in machinery? What are they used for?

- Hangfa, Hangfa, a scar on the hearts of machine processing workers

- How to mill a large arc surface with a small cutter?

- Dynamics of the processing center of the process! What is the fundamental reason

- 500 ° C ultra -strong aluminum alloy! This problem is overcome

- How much do you know about the hometown of machine tools and molds, how much do

BACK

BACK MT HOME

MT HOME Navbar

Navbar