500 ° C ultra -strong aluminum alloy! This problem is overcome

2024.05.09

Recently, the professor of the School of Materials of Tianjin University has developed a new type of oxide to enhance aluminum alloy, which increased the service temperature of aluminum alloy from 350 ° C to 500 °C. It overcome the problem of the application of aluminum alloy that is difficult to apply at high temperature environment above 400 ° C. Related research results are published in the journal "Natural Materials" in the "Natural Materials".

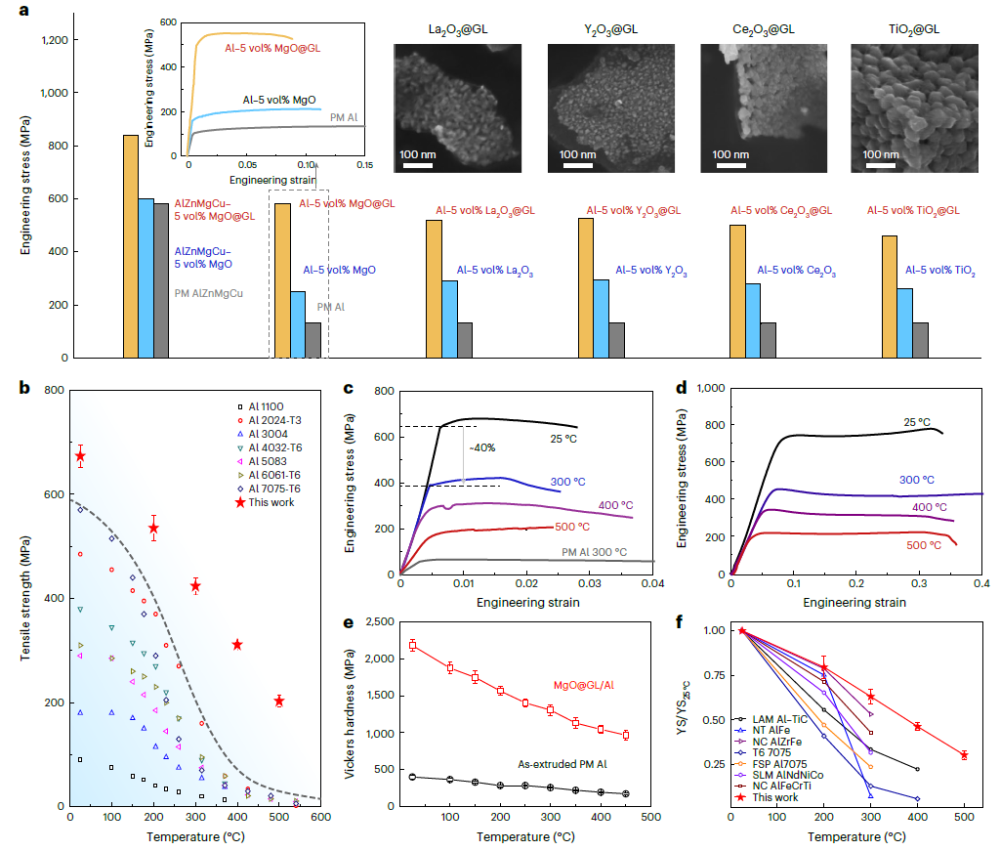

The picture shows the uniform dispersing of the ultra -fine oxide nanoparticles in the aluminum base.

The major needs of speed -up weight reduction in important areas such as aerospace and transportation, and have put forward higher requirements for the heat resistance of light metal materials. Although aluminum alloy has the advantages of low density, high strength, and corrosion resistance, due to poor heat resistance, the high temperature performance of aluminum alloy is the most concerned about 350 ° C -500 ° C in the current aerospace field. The key shortcomings that affect service safety. Therefore, it is of great significance to continue to promote the research and development of high -performance heat -resistant aluminum alloy, especially for high -temperature -resistant aluminum alloy materials for 350 ° C -500 ° C.

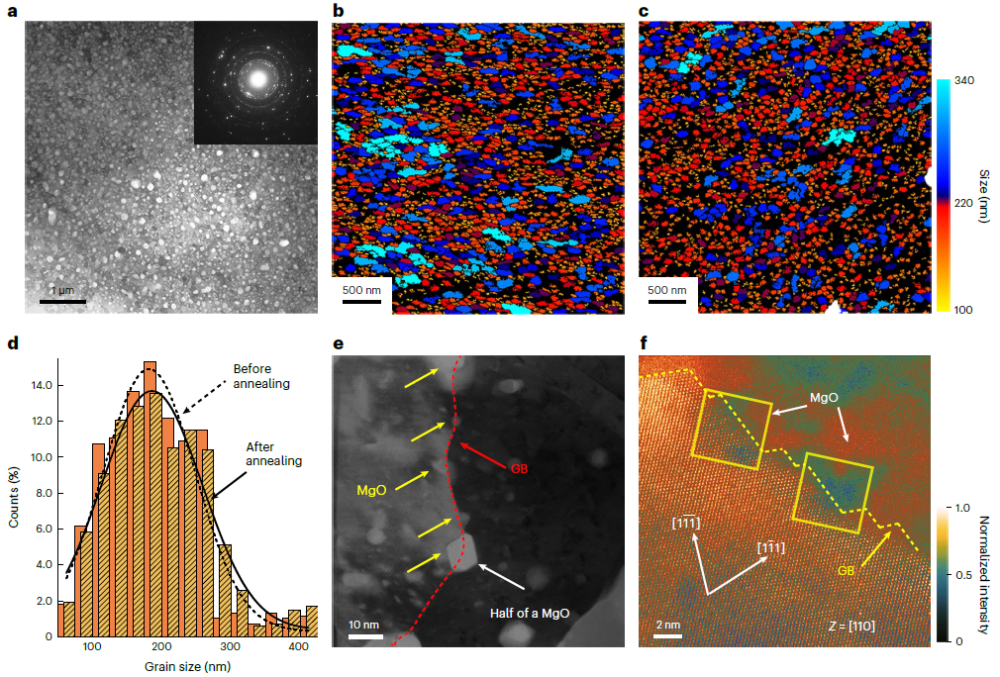

To this end, He Chunnian's team successfully improved the high temperature resistance of aluminum alloy through the introduction of high content, ultra -fine size and uniform dispersed nano -oxide particles in aluminum alloy. In the research, the team proposed a new preparation idea, solved the dispersed problems of the long -awaited nanoparticles, and transformed the most ideal material into reality. In the end, the stretching strength (200 MPA) of the new aluminum alloy developed at 500 ° C is more than 6 times compared to traditional aluminum alloy, and the high temperature stability increases by several orders of magnitude.

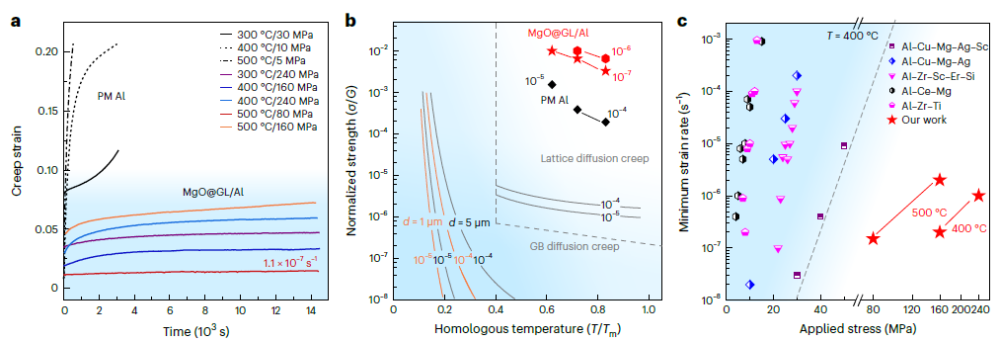

The picture shows the excellent creep performance of the material.

After the research work was published, Professor Alexis Deschamps, an internationally renowned metal material expert, and the National Institute of Technology in Gleoro, France, made a detailed comment and in -depth interpretation of the importance and potential impact of this work. The new strategy of enhanced alloy design of nano oxides has made the prepared aluminum alloy still have unprecedented stretching strength and anti -high -temperature creep performance when it is as high as 500 ° C. It has opened up a new field for the application of aluminum alloy in high temperature environments. "

The picture shows high temperature stability with excellent materials.

He Chunnian said: "This new process is simple, the cost of material is low, and easy to produce, so it has significant industrial application value. We are cooperating with industry leaders and scientific research institutes. Research on the preparation of thermal aluminum alloy to vigorously promote the implementation of the material of the material. "

Previous:Dynamics of the processing center of the process! What is the fundamental reason?

Related Information

- Industry news

- The tap or drill bit breaks in the hole, how to fix it?

- Why do airplanes use rivets instead of welding?

- Why are engineering drawings all blueprints?

- How is a ping pong ball made? It turns out that it is made of two pieces of plas

- What to do if quality is abnormal? Doing these 3 things well is the key!

- Weekly News 9.7-9.13

- Huawei's three-fold screen is approaching, and the domestic supply chain is wait

- Innovative application of digital twin technology in integrated die-casting prod

- 5 types of carbide cutting tools, what are the differences? Save this article an

- Global manufacturing PMI in June was 49.5% | Weekly News 7.6-7.12

- Raw material defects | Machining special operations and practical cases 109

- No wonder Toyota stamping is so good: a day in the life of a Toyota stamping sho

- Analysis on the development trend and demand of China's mold industry

- How many types of sealing rings are there in machinery? What are they used for?

- Hangfa, Hangfa, a scar on the hearts of machine processing workers

- How to mill a large arc surface with a small cutter?

- Dynamics of the processing center of the process! What is the fundamental reason

- 500 ° C ultra -strong aluminum alloy! This problem is overcome

- How much do you know about the hometown of machine tools and molds, how much do

BACK

BACK MT HOME

MT HOME Navbar

Navbar