How to mill a large arc surface with a small cutter?

2024.05.30

A method for machining long shallow arc grooves is introduced. On a milling machine or boring machine, through theoretical calculation, the universal angle boring and milling head is tilted at a certain angle, an elliptical arc is used to approximately replace the arc, and a small cutter head is used to mill a large arc surface.

1 Introduction

During the processing of a product in our factory, the processing difficulty of the right side plate is high and the precision requirement is high. The plate size is 2200mmx1650mm, the plate thickness is 47mm, the parallelism requirement is 0.04mm, the parallelism requirement of the guide rail surface is 0.015mm, and the thinnest part of the plate is only 14mm, which is very easy to deform during processing. There is a circular arc groove with a depth of 19mm, R60.75mm and a length of 1630mm in the middle of the plate. If ordinary boring is used, it is impossible to process the shallow long circular arc groove; if a ball cutter is used for layered processing, firstly, the processing time is long, and secondly, the spindle speed of our factory's heavy gantry milling machine cannot meet the requirements, and deformation is very easy to occur during processing. Therefore, how to achieve efficient processing while better controlling deformation has become a bottleneck problem that needs to be solved urgently in actual production.

Combined with previous processing experience, the solution of rotating the universal angle head to a fixed angle and using a small cutter head to mill a longer shallow circular arc groove [1] can solve the processing problem.

2 Processing principle

Tilt the machine tool spindle (universal angle head) at a certain angle, use a small cutter head along the machining axis motion trajectory to approximate the machining arc, and use a small cutter head to machine a large radius arc surface. The tilt angle of the spindle or universal angle head can be determined by theoretical calculation first. Then, the error between the elliptical arc and the actual arc can be confirmed by drawing software before final processing [2].

3 Design calculation

In order to use a small cutter head to machine an ideal arc surface, the tilt angle of the angle milling head must be calculated first, and a milling cutter head of appropriate size must be selected to perform a simulated error test on a computer [3].

3.1 Angle β of the angle milling head

The calculation formula for the angle milling head angle B is as follows:

sinβ={d+[d-4h(D-h) ]1/2 (D-h) ] (1)

Where, d is the milling cutter diameter (mm); D is the workpiece arc diameter (mm); and h is the arc chord height of the workpiece being machined (mm).

3.2 Selection of minimum and maximum limit values of disc milling cutter diameter d

Should satisfy: the chord length L of the milled arc opening ≤ disc milling cutter diameter d ≤ diameter D of the milled arc. The chord length L of the processed arc can be calculated according to formula (2)

L=2[h (D-h)]n (2)

The actual selected milling cutter diameter d shall not be less than L, and the larger the better. When the disc diameter d is closer to the processed arc diameter D, the accuracy is higher and the angle of the angle milling head is larger.

4 Processing application

The milling method of processing large diameter arcs with small diameter milling cutters in our factory is introduced as follows.

4.1 Selection and calculation of processing parameters

According to the drawings and process requirements, the arc groove length is 1630mm, the processing arc groove radius is 60.75mm, the diameter is 121.5mm, the processing arc chord height is 19.75mm, and the disc diameter is 90~121.5mm. The cutter disc should be as large as possible. Our factory happens to have a milling cutter disc with a diameter of 115 mm. The cutter disc diameter d = 115 mm, the arc diameter D = 121.5 mm, and the chord height h = 19.75 mm are substituted into formula (1) to calculate β = 66.79°. The angle is within the reasonable processing range of the universal angle head and meets the processing conditions.

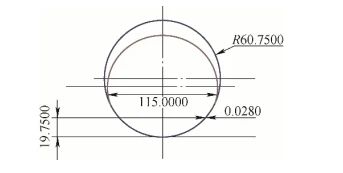

4.2 Use drawing software to check the accuracy error of the arc segment during processing

As shown in Figure 1, after the circle with a diameter of 115 mm is tilted by 66.79° through CAD software, it is projected into an ellipse with a major semi-axis length of 115 mm and a minor semi-axis length of 105.69 mm. The circle with a processing arc diameter of 121.5 mm is tangent to the large arc below the ellipse, and the chord height h = 19.75 mm is intercepted to check the error value between the processing arc and the elliptical arc after the cutter disc is tilted.

As can be seen from Figure 1, the processed arc is highly consistent with the elliptical arc formed after the cutter disc is tilted, and the difference is only 0.028mm, which fully meets the processing requirements. This method is feasible.

4.3 Processing example

Select a cutter disc with a diameter of 115mm, rotate the universal angle head 66.79°, and perform milling of the arc surface, which will greatly improve the efficiency. This method is suitable for processing shallow arc grooves with large D values, small chord height h, and long lengths. It can greatly simplify the processing steps and improve the processing efficiency. The effect after processing is shown in Figure 2.

5 Conclusion

This method is easy to operate and has high processing efficiency. It can be implemented on ordinary milling machines, especially for long shallow arc surfaces. It has considerable advantages for difficult to process, time-consuming and labor-intensive situations. In order to ensure the accuracy and quality of arc groove processing on ordinary milling machines, on the basis of the arc approximation method principle, the arc surface processing tool should be scientifically selected, and the angle milling head deflection angle should be determined reasonably. Through simulation error inspection, the quality and comprehensive efficiency of the approximate milling of the arc groove by the small cutter head can be guaranteed.

For inquiry and quotation of CNC custom service, please contact :

Phone /Wechat/Whatsapp: +86 13612776575

E-mail:sales03@dgmtwj.cn

Previous:Hangfa, Hangfa, a scar on the hearts of machine processing workers

Next:Dynamics of the processing center of the process! What is the fundamental reason?

Related Information

- Industry news

- The tap or drill bit breaks in the hole, how to fix it?

- Why do airplanes use rivets instead of welding?

- Why are engineering drawings all blueprints?

- How is a ping pong ball made? It turns out that it is made of two pieces of plas

- What to do if quality is abnormal? Doing these 3 things well is the key!

- Weekly News 9.7-9.13

- Huawei's three-fold screen is approaching, and the domestic supply chain is wait

- Innovative application of digital twin technology in integrated die-casting prod

- 5 types of carbide cutting tools, what are the differences? Save this article an

- Global manufacturing PMI in June was 49.5% | Weekly News 7.6-7.12

- Raw material defects | Machining special operations and practical cases 109

- No wonder Toyota stamping is so good: a day in the life of a Toyota stamping sho

- Analysis on the development trend and demand of China's mold industry

- How many types of sealing rings are there in machinery? What are they used for?

- Hangfa, Hangfa, a scar on the hearts of machine processing workers

- How to mill a large arc surface with a small cutter?

- Dynamics of the processing center of the process! What is the fundamental reason

- 500 ° C ultra -strong aluminum alloy! This problem is overcome

- How much do you know about the hometown of machine tools and molds, how much do

BACK

BACK MT HOME

MT HOME Navbar

Navbar