CNC processing process interruption/or cutting knife delete procedure skills

2023.02.03

First of all, we need to understand the state of the NC system operation

1. Mode information, the most basic is the coordinate system, G90; G54 is generally used by default to use the first coordinate system

2, tool number, knife length modal information,

3, interrupt position, or knife number

If this information, some machine tools will be reset if the modal information is reset after the reset is pressed, so if you stop before stop

Case 1 Volkswagen usage

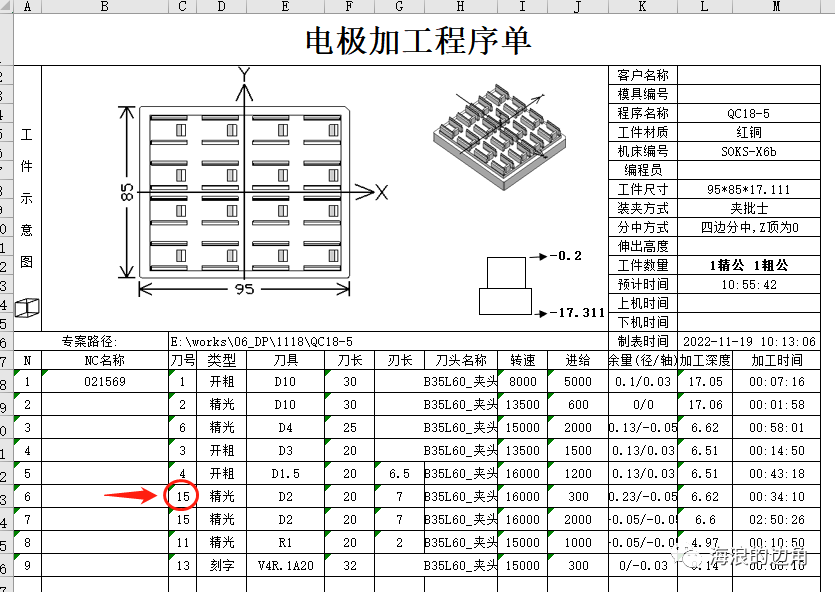

We have a knife wear/broken knife here when we process it to T15. We need to replace the tool and return to the T15 knife number to continue processing

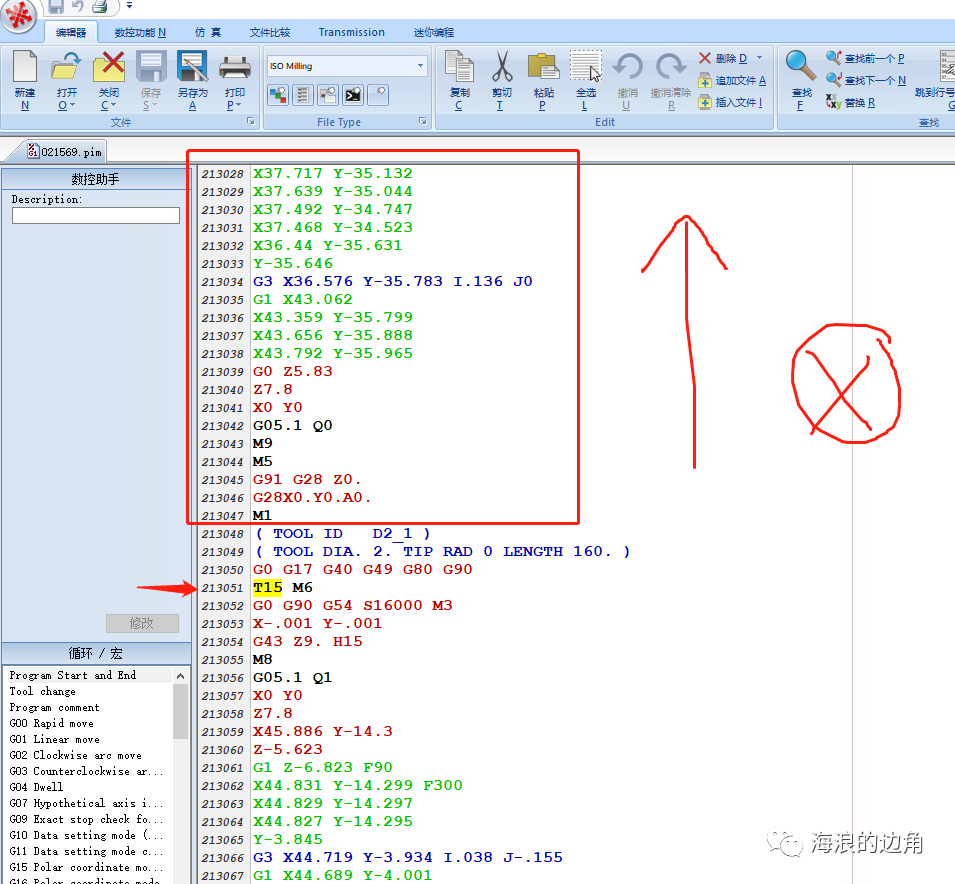

Use this software to open the NC program picture , this software has a download connection in my public account

, this software has a download connection in my public account

Open Program-> Search T15

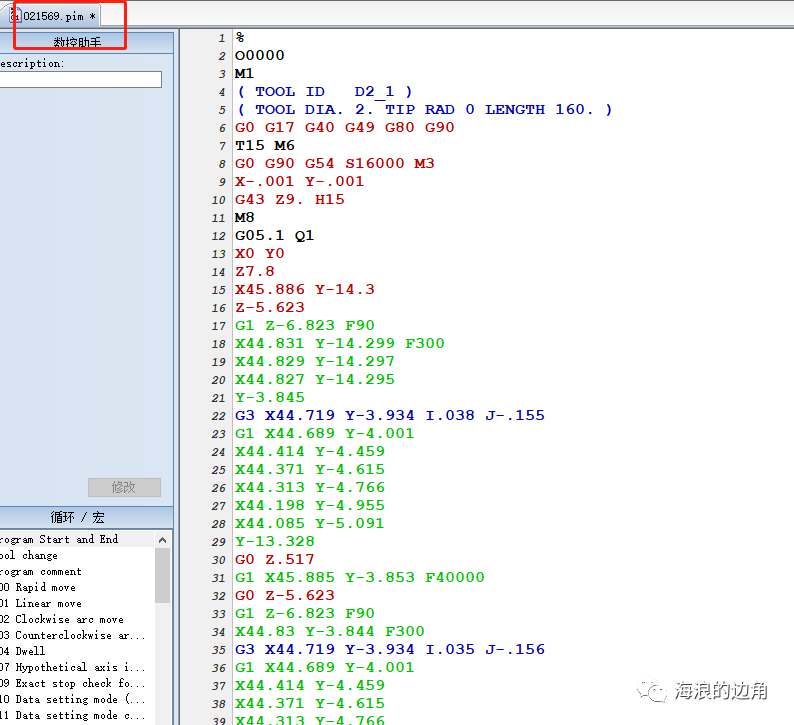

Delete all above the box and keep T15M6. Here is the start of the line

You also need to observe the procedures for the following lines to activate modular information. If you do n’t need to add it yourself, there will be risk of crash !!!

Let me explain the program header: G0 G90 G54 S16000 m3

Here G90 selects the absolute value processing mode, G54 selects workpieces coordinates,

G43Z9.H15

Here G43 startup knife length 15 compensation Z axis move to Z9.0

The following is the deleted program

After the program is deleted, you must simulation, and you must start slowly on the machine tool.

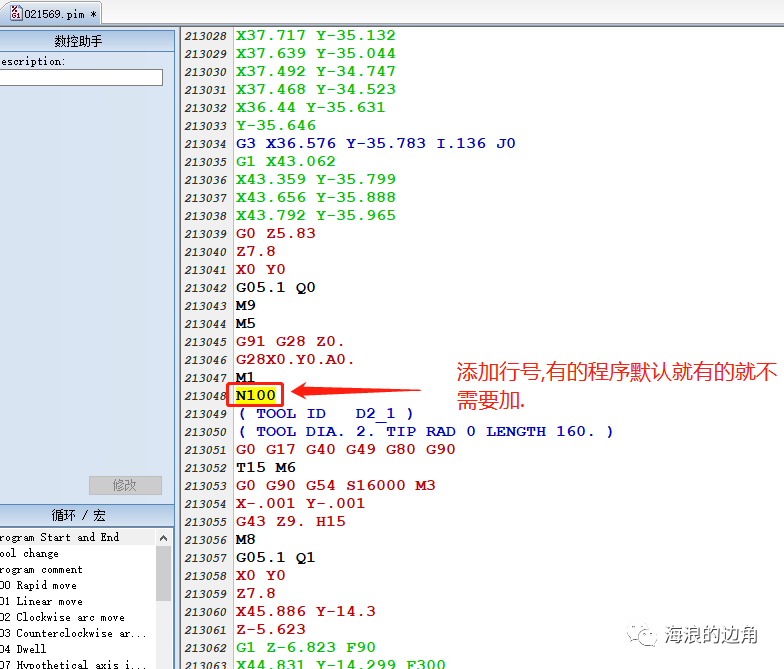

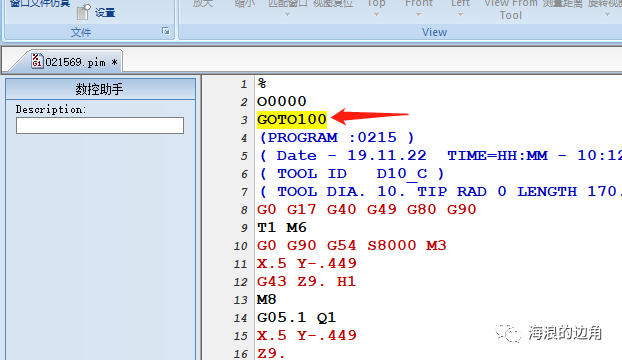

Example 2 uses the GOTO program jump function. This is a high -level function. Some low -operated machines may not have this function.

Interrupt position plus N100 (100 is a custom value)

The program starts to add GOTO 100

This is fine, convenient and simple, you need to wait for a period of time when starting the program. The system needs to be calculated

The above two methods can generally solve the problem. It is still more complicated to share with you.

Previous:Robot design-non-standard mechanical design

Next:Metal material corrosion is very worthy of attention

Related Information

- Industry news

- The tap or drill bit breaks in the hole, how to fix it?

- Why do airplanes use rivets instead of welding?

- Why are engineering drawings all blueprints?

- How is a ping pong ball made? It turns out that it is made of two pieces of plas

- What to do if quality is abnormal? Doing these 3 things well is the key!

- Weekly News 9.7-9.13

- Huawei's three-fold screen is approaching, and the domestic supply chain is wait

- Innovative application of digital twin technology in integrated die-casting prod

- 5 types of carbide cutting tools, what are the differences? Save this article an

- Global manufacturing PMI in June was 49.5% | Weekly News 7.6-7.12

- Raw material defects | Machining special operations and practical cases 109

- No wonder Toyota stamping is so good: a day in the life of a Toyota stamping sho

- Analysis on the development trend and demand of China's mold industry

- How many types of sealing rings are there in machinery? What are they used for?

- Hangfa, Hangfa, a scar on the hearts of machine processing workers

- How to mill a large arc surface with a small cutter?

- Dynamics of the processing center of the process! What is the fundamental reason

- 500 ° C ultra -strong aluminum alloy! This problem is overcome

- How much do you know about the hometown of machine tools and molds, how much do

BACK

BACK MT HOME

MT HOME Navbar

Navbar