Seven common metal materials

2022.08.05

1 Cast iron - fluidity

Sewer covers are such an inconspicuous part of our everyday environment that few people pay attention to them. Cast iron has such a large and wide range of uses mainly because of its excellent fluidity and its ease of pouring into a variety of complex forms. Cast iron is actually the name given to a mixture of elements, including carbon, silicon, and iron. The higher the carbon content, the better the flow characteristics during casting. Carbon is present here in two forms, graphite and iron carbide.

The presence of graphite in cast iron gives sewer covers excellent wear resistance. Rust is generally only present on the outermost layer, so it is usually polished. Even so, there are still special measures to prevent rust during the pouring process, that is, a layer of asphalt coating is applied on the surface of the casting, and the asphalt penetrates into the pores on the surface of the cast iron to prevent rust. The traditional process of producing sand casting materials is now used by many designers in other newer and more interesting areas.

Material characteristics: excellent fluidity, low cost, good wear resistance, low solidification shrinkage, very brittle, high compressive strength, good machinability.

Typical Uses: Cast iron has been used for hundreds of years in construction, bridges, engineering components, household, and kitchen appliances.

2 Stainless steel - stainless love

Stainless steel is an alloy made by incorporating chromium, nickel, and other metallic elements into steel. Its rust-free feature comes from the composition of chromium in the alloy. Chromium forms a strong and self-healing chromium oxide film on the surface of the alloy, which is invisible to the naked eye. The ratio of stainless steel and nickel we usually refer to is generally 18:10. The term "stainless steel" does not simply refer to one type of stainless steel, but to more than one hundred industrial stainless steels, each developed to perform well in its specific field of application.

In the early 20th century, stainless steel was introduced into the field of product design, and designers developed many new products around its toughness and corrosion resistance properties, involving many areas that had never been explored before. This series of design attempts is very revolutionary: for example, the equipment that can be used again after sterilization appears for the first time in the medical industry.

Stainless steel is divided into four main types: austenite, ferrite, ferritic-austenite (composite), and martensite. Stainless steel used in household items is basically austenitic.

Material properties: health care, anti-corrosion, fine surface treatment, high rigidity, can be formed by various processing techniques, difficult to cold work.

Typical use: Among the common primary color stainless steels, austenitic stainless steel is the most suitable coloring material, which can obtain satisfactory color appearance and shape. Austenitic stainless steel is mainly used in decorative building materials, household goods, industrial pipes and building structures; martensitic stainless steel is mainly used for making knives and turbine blades; ferritic stainless steel is corrosion-resistant and is mainly used in durable washing machines and In boiler parts; composite stainless steel has stronger corrosion resistance, so it is often used in aggressive environments.

3 Zinc - 730 pounds in a lifetime

Zinc, silvery and slightly bluish-gray, is the third most widely used non-ferrous metal after aluminum and copper. A statistic from the U.S. Bureau of Mines shows that an average person consumes a total of 331 kilograms of zinc in his lifetime. Zinc has a very low melting point, so it is also an ideal casting material.

Zinc castings are very common in our daily life: materials under the surface of doorknobs, faucets, electronic components, etc., zinc has extremely high corrosion resistance, this feature makes it have another most basic function, namely As a surface coating material for steel. In addition to these functions, zinc is also an alloy material for synthesizing brass with copper. Its corrosion resistance doesn't just apply to steel surface coatings - it also helps strengthen our human immune system.

Material characteristics: health care, anti-corrosion, excellent castability, excellent corrosion resistance, high strength, high hardness, cheap raw materials, low melting point, creep resistance, easy to form alloys with other metals, health care, normal temperature Fragile, malleable around 100 degrees Celsius.

Typical use: electronic product components. Zinc is one of the alloying materials that form bronze. Zinc also has hygienic and anti-corrosion properties. In addition, zinc is also used in roofing materials, photo engraving disks, mobile phone antennas, and shutter devices in cameras.

4 Aluminium (AL) - a modern material

Compared with gold, which has a history of 9,000 years, aluminum, a white metal with a slight blue light, can only be regarded as a baby among metal materials. Aluminium was introduced and named in the early 18th century. Unlike other metal elements, aluminum does not exist in nature as a direct metal element, but is extracted from bauxite containing 50% alumina (also known as bauxite). Aluminium, found in minerals in this form, is also one of the most abundant metallic elements on our planet.

When aluminum first appeared, it was not immediately applied to people's lives. Later, a series of new products for its unique functions and characteristics gradually came out, and this high-tech material gradually has a wider and wider market. Although the application history of aluminum is relatively short, the output of aluminum products on the market now far exceeds the sum of other non-ferrous metal products.

Material properties: flexible and malleable, easy to alloy, high strength-to-weight ratio, excellent corrosion resistance, easy to conduct electricity and heat, recyclable.

Typical uses: vehicle skeletons, aircraft parts, kitchen utensils, packaging and furniture. Aluminum is also often used to strengthen some large building structures, such as the statue of Eros on Piccadilly Circus in London, and the top of the Chrysler Automobile Building in New York.

5 magnesium alloy - ultra-thin aesthetic design

Magnesium is an extremely important non-ferrous metal. It is lighter than aluminum and can form high-strength alloys with other metals. Magnesium alloys have light specific gravity, high specific strength and specific stiffness, good thermal conductivity and good damping. Shock and electromagnetic shielding performance, easy to process and shape, easy to recycle and so on. But for a long time, due to the high price and technical limitations, magnesium and magnesium alloys are only used in a small amount in the aviation, aerospace and military industries, so they are called "noble metals". Today, magnesium is the third largest metal engineering material after steel and aluminum, and is widely used in aerospace, automotive, electronics, mobile communications, metallurgy and other fields. It can be expected that the importance of metallic magnesium will become greater in the future due to the increase in the production cost of other structural metals.

The proportion of magnesium alloy is 68% of aluminum alloy, 27% of zinc alloy, and 23% of steel. It is often used in automobile parts, 3C product shells, building materials, etc. Most ultra-thin laptop and mobile phone casings are made of magnesium alloys. Since the last century, human beings still have an undeniable love for metal texture and luster. Although plastic products can form a metal-like appearance, their luster, hardness, temperature and texture are still different from those of metals. As a new type of metal raw material, magnesium alloy gives people a feeling of high-tech products.

The corrosion resistance of magnesium alloys is 8 times that of carbon steel, 4 times that of aluminum alloys, and more than 10 times that of plastics. The corrosion resistance is the best among the alloys. Commonly used magnesium alloys are non-flammable, especially when used in automobile parts and building materials, which can avoid instantaneous combustion. The reserves of magnesium in the earth's crust ranks eighth, and most of the magnesium raw materials are extracted from seawater, so its resources are stable and sufficient.

Material characteristics: lightweight structure, high rigidity and impact resistance, excellent corrosion resistance, good thermal conductivity and electromagnetic shielding, good non-flammability, poor heat resistance, easy to recycle.

Typical uses: Widely used in aerospace, automotive, electronics, mobile communications, metallurgy and other fields.

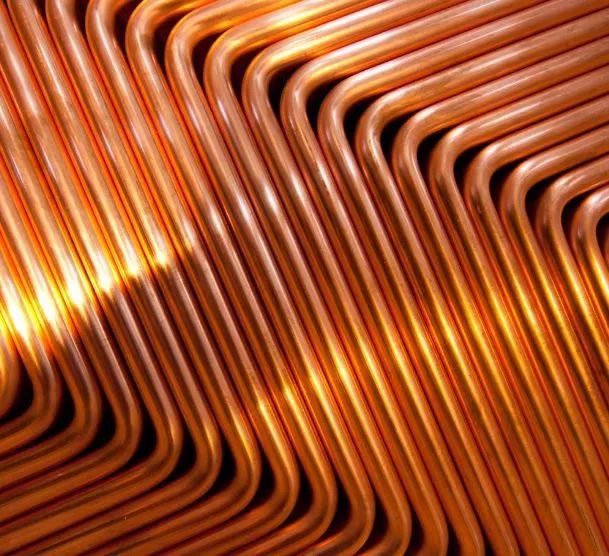

6 Copper - the partner of mankind

Copper is an incredibly versatile metal that is so closely related to our lives. Many of mankind's early tools and weapons were made of copper. Its Latin name "cuprum" originated from a place called Cyprus, which is an island rich in copper resources. People named this metal material with the abbreviation Cu of the island's name, so copper has its current code name.

Copper plays a very important role in modern society: it is widely used in building structures, as a carrier for transmitting electricity, and for thousands of years, it has been used by people of many different cultural backgrounds as a raw material for making body decorations . This malleable, orange-red metal has been with us all the way from simple decoding and transmission to its pivotal role in complex modern communications applications. Copper is an excellent electrical conductor, second only to silver in its conductivity. In terms of the time history of people's use of metal materials, copper is the oldest metal used by mankind after gold. This is largely because copper is easy to mine and the industry is relatively easy to separate from copper.

Material characteristics: good corrosion resistance, excellent thermal conductivity, electrical conductivity, hardness, flexibility, ductility, unique effect after polishing.

Typical Uses: Wires, engine coils, printed circuits, roofing materials, plumbing materials, heating materials, jewelry, cookware. It is also one of the main alloying components for making bronze.

7 Chromium - high-finish post-treatment

Chromium is most commonly found in stainless steel as an alloying element to increase its hardness. Chrome plating processes are generally divided into three types: decorative plating, hard chrome plating, and black chrome plating. Chrome plating is widely used in the engineering field. Decorative chrome plating is usually used as the outermost layer on the outside of the nickel layer, and the plating has a delicate and mirror-like polishing effect. As a decorative finishing step, the chrome layer is only 0.006 mm thick. When planning to use the chrome plating process, the dangers of this process must be fully considered. In the past decade, there has been an increasing trend of hexavalent decorative chromium water being replaced by trivalent chromium water, because the former is very carcinogenic, while the latter is considered to be relatively less toxic.

Material characteristics: very high finish, excellent corrosion resistance, hard and durable, easy to clean, low coefficient of friction.

Typical Uses: Decorative chrome is the coating material for many automotive components, including door handles and bumpers, in addition to bicycle parts, bathroom faucets, and furniture, kitchen utensils, tableware, and more. Hard chrome plating is more used in industrial fields, including random access memory in job control blocks, jet engine components, plastic molds, and shock absorbers. Black chrome plating is mainly used for musical instrument decoration and solar energy utilization.

Previous:An overview of the four strength theories

Next:Welding performance of metal materials

Related Information

- Industry news

- The tap or drill bit breaks in the hole, how to fix it?

- Why do airplanes use rivets instead of welding?

- Why are engineering drawings all blueprints?

- How is a ping pong ball made? It turns out that it is made of two pieces of plas

- What to do if quality is abnormal? Doing these 3 things well is the key!

- Weekly News 9.7-9.13

- Huawei's three-fold screen is approaching, and the domestic supply chain is wait

- Innovative application of digital twin technology in integrated die-casting prod

- 5 types of carbide cutting tools, what are the differences? Save this article an

- Global manufacturing PMI in June was 49.5% | Weekly News 7.6-7.12

- Raw material defects | Machining special operations and practical cases 109

- No wonder Toyota stamping is so good: a day in the life of a Toyota stamping sho

- Analysis on the development trend and demand of China's mold industry

- How many types of sealing rings are there in machinery? What are they used for?

- Hangfa, Hangfa, a scar on the hearts of machine processing workers

- How to mill a large arc surface with a small cutter?

- Dynamics of the processing center of the process! What is the fundamental reason

- 500 ° C ultra -strong aluminum alloy! This problem is overcome

- How much do you know about the hometown of machine tools and molds, how much do

BACK

BACK MT HOME

MT HOME Navbar

Navbar