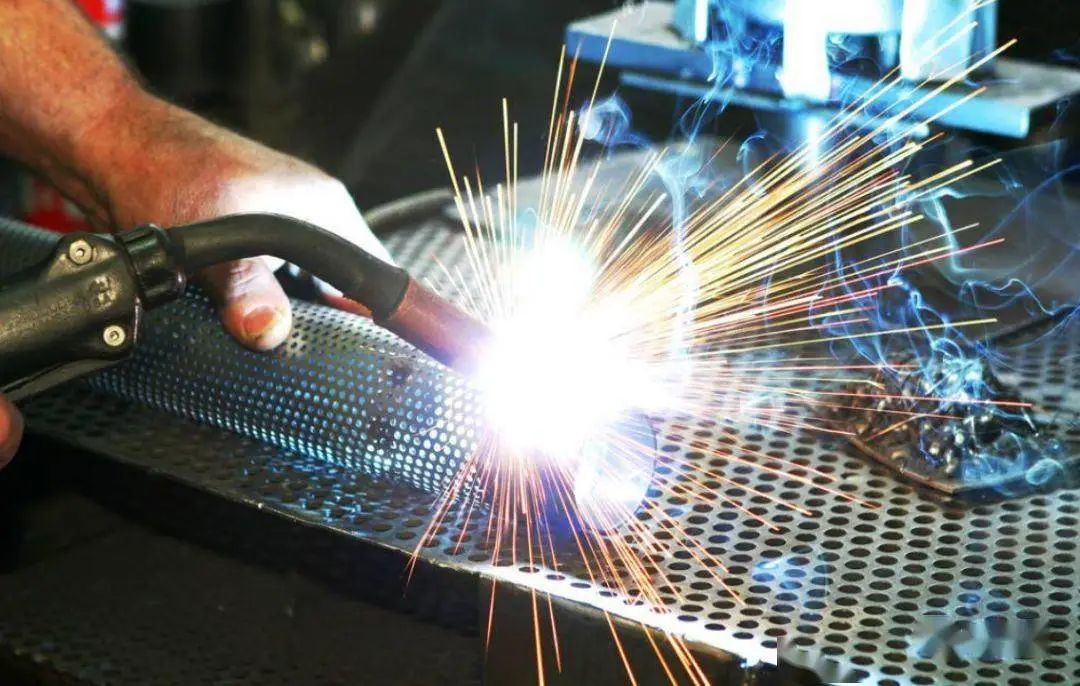

Welding performance of metal materials

2022.07.28

Welding performance concept for metallic materials

The weldability of metal materials refers to the ability of metal materials to obtain excellent welded joints under certain welding processes including welding methods, welding materials, welding specifications and welding structure forms. A metal is considered to have good welding performance if good welded joints can be obtained by using more common and simple welding processes. The weldability of metal materials is generally divided into two aspects: process weldability and use weldability.

Process weldability:

refers to the ability to obtain excellent, defect-free welded joints under certain welding process conditions. It is not an inherent property of the metal, but an evaluation based on a certain welding method and the specific process measures used. Therefore, the process weldability of metal materials is closely related to the welding process.

Use weldability:

refers to the degree to which the welded joint or the entire structure meets the service performance specified in the product technical conditions. The performance depends on the working conditions of the welded structure and the technical requirements put forward in the design. It usually includes mechanical properties, low temperature toughness, brittle fracture resistance, high temperature creep, fatigue properties, durable strength, corrosion resistance and wear resistance. For example, the commonly used S30403 and S31603 stainless steels have excellent corrosion resistance, and 16MnDR and 09MnNiDR low temperature steels also have good low temperature toughness properties.

Influencing factors of welding performance of metal materials

1 Material factor

Materials include base metal and welding materials. Under the same welding conditions, the main factors that determine the weldability of the base metal are its own physical properties and chemical composition.

In terms of physical properties: factors such as the melting point, thermal conductivity, linear expansion coefficient, density, and heat capacity of the metal all affect the thermal cycle, melting, crystallization, phase transformation and other processes, thereby affecting the weldability. Materials with low thermal conductivity such as stainless steel have large temperature gradient, high residual stress and large deformation during welding. Moreover, due to the long residence time at high temperature, the grains in the heat-affected zone grow, which is detrimental to the joint performance. Austenitic stainless steel has a large coefficient of linear expansion, and the deformation and stress of the joint are more serious.

In terms of chemical composition, the most influential element is carbon, that is to say, the amount of carbon in the metal determines its weldability. Most of the other alloying elements in steel are also not conducive to welding, but their effect is generally much less than that of carbon. When the carbon content in the steel increases, the hardening tendency increases, the plasticity decreases, and welding cracks are prone to occur. Usually, the susceptibility of metal materials to cracks during welding and the changes in mechanical properties of welded joints are used as the main indicators for evaluating the weldability of materials. Therefore, the higher the carbon content, the worse the weldability. Low carbon steel and low alloy steel with carbon content less than 0.25% have excellent plasticity and impact toughness, and the plasticity and impact toughness of welded joints after welding are also good. There is no need for preheating and post-weld heat treatment during welding, and the welding process is easy to control, so it has good weldability.

In addition, the smelting and rolling state, heat treatment state, and microstructure state of the steel all affect the weldability to varying degrees. The weldability of steel is improved by means of refining, refining or grain refinement and controlled rolling.

Welding materials directly participate in a series of chemical metallurgical reactions in the welding process, which determine the composition, structure, properties and formation of defects of the weld metal. If the welding material is improperly selected and does not match the base metal, it will not only fail to obtain a joint that meets the requirements of use, but also introduce defects such as cracks and changes in structure and properties. Therefore, the correct selection of welding materials is an important factor to ensure high-quality welded joints.

2 Process factors

Process factors include welding method, welding process parameters, welding sequence, preheating, post-heating and post-weld heat treatment. The welding method has a great influence on the weldability, mainly in two aspects: heat source characteristics and protection conditions.

Different welding methods have different heat sources in terms of power, energy density, and maximum heating temperature. Metals welded under different heat sources will show different welding properties. For example, the power of electroslag welding is very high, but the energy density is very low, the maximum heating temperature is not high, the heating is slow during welding, and the high temperature residence time is long, which makes the grains in the heat affected zone coarse and the impact toughness is significantly reduced, which must be normalized. improve. On the contrary, electron beam welding, laser welding and other methods have low power, but high energy density and rapid heating. The high temperature residence time is short, the heat affected zone is very narrow, and there is no danger of grain growth.

Adjusting the welding process parameters, taking other process measures such as preheating, post-heating, multi-layer welding and controlling the temperature between layers, can adjust and control the welding thermal cycle, thereby changing the weldability of the metal. If measures such as preheating before welding or post-welding heat treatment are taken, it is entirely possible to obtain welded joints without crack defects and meeting the performance requirements.

3 Structural Factors

It mainly refers to the design form of welded structure and welded joint, such as the influence of structural shape, size, thickness, joint groove form, welding seam layout and its cross-sectional shape on weldability. Its influence is mainly manifested in the transfer of heat and the state of force. Different plate thicknesses, different joint forms or groove shapes have different heat transfer speed directions and heat transfer speeds, thus affecting the crystallization direction and grain growth of the molten pool. The opening and closing of the structure, the thickness of the plate and the arrangement of the welds, etc., determine the stiffness and restraint of the joint, and have an impact on the stress state of the joint. Poor crystal morphology, severe stress concentration and excessive welding stress are the basic conditions for the formation of welding cracks. In the design, reducing the stiffness of joints, reducing cross welds, and reducing various factors that cause stress concentration are important measures to improve weldability.

4 Conditions of use

It refers to the working temperature, load conditions and working medium of the welded structure during service. These working environments and operating conditions require welding structures to have corresponding performance. For example, the welded structure working at low temperature must have brittle fracture resistance; the structure working at high temperature must have creep resistance; the structure working under alternating load has good fatigue resistance; working in acid, alkali or salt medium The welded container should have high corrosion resistance and so on. In short, the harsher the conditions of use, the higher the quality requirements for welded joints, and the more difficult it is to ensure the weldability of materials.

Identification and evaluation index of weldability of metal materials

During the welding process, the product undergoes welding thermal process, metallurgical reaction, as well as welding stress and deformation, resulting in changes in chemical composition, metallographic structure, size and shape, so that the performance of welded joints is often different from that of the base metal, and sometimes even The usage requirements cannot be met. For many active metals or refractory metals, special welding methods, such as electron beam welding or laser welding, should be used in order to obtain high-quality joints. The less equipment conditions and the less difficulty a material requires to make a good welded joint, the better the weldability of the material; on the contrary, complex and expensive welding methods, special welding materials and process measures are required, indicating that this material poor weldability.

When manufacturing products, the weldability of the materials used must be evaluated first to judge whether the selected structural materials, welding materials and welding methods are appropriate. There are many methods for evaluating the weldability of materials, and each method can only describe a certain aspect of the weldability, so it is necessary to conduct tests to fully determine the weldability. Test methods can be divided into simulation type and experimental type. The former simulates welding heating and cooling characteristics; the latter is tested according to actual welding conditions. The main contents of the test are to detect the chemical composition, metallographic structure, mechanical properties, and the presence or absence of welding defects of the base metal and weld metal, and to determine the low-temperature properties, high-temperature properties, corrosion resistance and crack resistance of welded joints.

Method for estimating and testing the weldability of metallic materials

1 Indirect evaluation method of process weldability

Since the influence of carbon is the most obvious, the influence of other elements can be converted into the influence of carbon, so carbon equivalent is used to evaluate the quality of weldability.

Carbon equivalent calculation formula of carbon steel and low alloy structural steel:

When C E <0.4%, the plasticity of the steel is good, the hardening tendency is not obvious, and the weldability is good. Under the general welding technical conditions, the welded joint will not have cracks, but for thick and large parts or welding at low temperature, preheating should be considered;

When C E is 0.4-0.6%, the plasticity of the steel decreases, the hardening tendency increases gradually, and the weldability is poor. The workpiece needs to be properly preheated before welding and slow cooling after welding to prevent cracks;

When C E > 0.6%, the plasticity of steel deteriorates. The hardening tendency and cold crack tendency are large, and the weldability is worse. The workpiece must be preheated to a higher temperature, technical measures to reduce welding stress and prevent cracking should be taken, and appropriate heat treatment should be carried out after welding.

The larger the carbon equivalent value obtained from the calculation results, the greater the hardening tendency of the steel to be welded, and the heat-affected zone is prone to cold cracks. Therefore, when C E > 0.5%, the steel is easy to be hardened, and it must be preheated during welding to prevent cracks. , with the increase of plate thickness and CE, the preheating temperature should also increase accordingly.

2 Direct evaluation method of process weldability

Weld crack test method, cracks generated in welded joints can be divided into hot cracks, cold cracks, reheat cracks, stress corrosion, laminar tearing, etc.

(1) T-joint welding crack test method, this method is mainly used to evaluate the hot crack susceptibility of carbon steel and low alloy steel fillet welds, and can also be used to determine the influence of electrodes and welding parameters on hot crack susceptibility.

(2) Press plate butt welding crack test method, which is mainly used to evaluate the hot crack susceptibility of carbon steel, low alloy steel, austenitic stainless steel electrodes and welds. It is by installing the specimen in the FISCO test device, and adjusting the size of the groove gap has a great influence on the crack generation. With the increase of the gap, the crack sensitivity is greater.

(3) Rigid butt crack test method, this method is mainly used to measure hot cracks and cold cracks in the weld area, as well as cold cracks in the heat-affected zone. The surrounding of the test piece is first welded with tack welds in the area with high rigidity. On the bottom plate, the test weld shall be welded according to the actual construction welding parameters during the test. It is mainly used for electrode arc welding. After welding, the test piece is placed at room temperature for 24 hours. First check the surface of the weld, and then cut off the sample abrasive sheet to check whether there is any Cracks are generally evaluated on the basis of cracking and no cracking, and two test pieces are welded for each condition.

Welding characteristics of commonly used metal materials

1 Welding of carbon steel

(1) Welding of low carbon steel

Low carbon steel has low carbon content, low manganese and silicon content, and will not cause serious structural hardening or quenching structure due to welding under normal circumstances. This steel has excellent plasticity and impact toughness, and the plasticity and toughness of its welded joints are also extremely good. Generally, there is no need for preheating and post-heating during welding, and no special technological measures are required to obtain welded joints with satisfactory quality. Therefore, low carbon steel has excellent welding performance and is the steel with the best welding performance among all steels. .

(2) Welding of medium carbon steel

The carbon content of medium carbon steel is higher, and its weldability is worse than that of low carbon steel. When C E is close to the lower limit (0.25%), the weldability is good. With the increase of carbon content, the hardening tendency increases, and the low plasticity martensitic structure is easily generated in the heat affected zone. When the rigidity of the weldment is large or the welding materials and process parameters are not selected properly, cold cracks are prone to occur. When the first layer of weld is welded by multi-layer welding, due to the large proportion of the base metal fused into the weld, its carbon content, sulfur and phosphorus content increase, and it is easy to produce hot cracks. In addition, when the carbon content is high, the stomatal sensitivity also increases.

(3) Welding of high carbon steel

High carbon steel with C E greater than 0.6% has high hardenability and is prone to produce hard and brittle high carbon martensite. Cracks are prone to occur in the weld and heat affected zone, making it difficult to weld. Therefore, such steels are generally not used to manufacture welded structures, but are used to manufacture high-hardness or wear-resistant components or parts, and most of their welding is the repair and repair of damaged parts. These parts and components should be annealed before welding to reduce welding cracks, and then heat treated again after welding.

2 Welding of low-alloy high-strength steels

The carbon content of low-alloy high-strength steel generally does not exceed 0.20%, and the total amount of alloying elements generally does not exceed 5%. It is precisely because low-alloy high-strength steel contains a certain amount of alloying elements that its welding performance is different from that of carbon steel. Its welding characteristics are as follows:

(1) Welding cracks in welded joints

Cold-cracked low-alloy high-strength steel contains elements such as C, Mn, V, and Nb that strengthen the steel, so it is easy to be hardened during welding, and these hardened structures are very sensitive. Therefore, in the case of high rigidity or high restraint stress, if Improper welding process can easily cause cold cracks. Moreover, such cracks have a certain delay, which is extremely harmful.

Reheat cracks (SR) cracks Reheat cracks are intergranular cracks that occur in the coarse-grained region near the fusion line during post-weld stress relief heat treatment or long-term high-temperature operation. It is generally believed that its occurrence is due to the fact that carbides such as V, Nb, Cr, Mo, etc. near the HAZ are dissolved in the austenite due to the high temperature of welding, and there is no time for precipitation during cooling after welding. , the creep deformation during stress relaxation is concentrated at the grain boundaries.

Low-alloy high-strength steel welded joints are generally not prone to reheat cracks, such as 16MnR, 15MnVR, etc. However, for Mn-Mo-Nb and Mn-Mo-V series low-alloy high-strength steels, such as 07MnCrMoVR, since Nb, V, and Mo are elements that promote reheat crack sensitivity, this type of steel should be treated during post-weld heat treatment. Care should be taken to avoid the sensitive temperature area of reheat cracks to prevent the occurrence of reheat cracks.

(2) Embrittlement and softening of welded joints

Strain aging embrittlement welded joints need to undergo various cold workings (cutting shearing, cylinder rolling, etc.) before welding, and the steel will undergo plastic deformation. . Strain aging embrittlement will reduce the plasticity of the steel and increase the brittle transition temperature, resulting in brittle fracture of the equipment. Post-weld heat treatment can eliminate such strain aging of the welded structure and restore the toughness.

Weld and HAZ Embrittlement Welding is a process of uneven heating and cooling, resulting in uneven structure. The brittle transition temperature of the weld (WM) and heat affected zone (HAZ) is higher than that of the base metal and is the weak link in the joint. Welding line energy has an important influence on the properties of low-alloy high-strength steel WM and HAZ. Low-alloy high-strength steel is easy to be hardened. If the line energy is too small, martensite will cause cracks in HAZ; if the line energy is too large, the grains of WM and HAZ will be coarse. Will cause joint embrittlement. Compared with hot-rolled and normalized steel, low-carbon quenched and tempered steel has a more serious tendency of HAZ embrittlement caused by excessive line energy. Therefore, when welding, the line energy should be limited to a certain range.

Softening of the heat-affected zone of welded joints Due to the heat of welding, the outside of the heat-affected zone (HAZ) of low-carbon quenched and tempered steel is heated above the tempering temperature, especially the area near Ac1, resulting in a softening zone with reduced strength. The softening of the structure in the HAZ zone increases with the increase of the welding line energy and the increase of the preheating temperature, but generally the tensile strength of the softened zone is still higher than the lower limit of the standard value of the base metal, so the heat-affected zone of this type of steel softens. As long as the problem is properly crafted, it will not affect the performance of its joints.

3 Welding of stainless steel

Stainless steel can be divided into four categories according to the structure of its steel, namely austenitic stainless steel, ferritic stainless steel, martensitic stainless steel, and austenitic-ferritic duplex stainless steel. The following mainly analyzes the welding characteristics of austenitic stainless steel and duplex stainless steel.

(1) Welding of austenitic stainless steel

Austenitic stainless steels are easier to weld than other stainless steels. No phase transformation occurs at any temperature, and it is not sensitive to hydrogen embrittlement. Austenitic stainless steel joints also have good plasticity and toughness in the welded state. The main problems of welding are: welding hot cracks, embrittlement, intergranular corrosion and stress corrosion. In addition, due to poor thermal conductivity, large coefficient of linear expansion, large welding stress and deformation. During welding, the welding heat input should be as small as possible, and the interlayer temperature should not be preheated. The interlayer temperature should be controlled below 60 °C, and the weld joints should be staggered. To reduce the heat input, the welding speed should not be increased excessively, but should be adapted to reduce the welding current.

(2) Welding of austenitic-ferritic duplex stainless steel

Austenitic-ferritic duplex stainless steel is a duplex stainless steel composed of austenite and ferrite. It combines the advantages of austenitic steel and ferritic steel, so it has the characteristics of high strength, good corrosion resistance and easy welding. At present, there are mainly three types of duplex stainless steels: CR18, CR21, and CR25. This type of steel welding

Previous:Seven common metal materials

Next:Calculation of bearing heating

Related Information

- Industry news

- The tap or drill bit breaks in the hole, how to fix it?

- Why do airplanes use rivets instead of welding?

- Why are engineering drawings all blueprints?

- How is a ping pong ball made? It turns out that it is made of two pieces of plas

- What to do if quality is abnormal? Doing these 3 things well is the key!

- Weekly News 9.7-9.13

- Huawei's three-fold screen is approaching, and the domestic supply chain is wait

- Innovative application of digital twin technology in integrated die-casting prod

- 5 types of carbide cutting tools, what are the differences? Save this article an

- Global manufacturing PMI in June was 49.5% | Weekly News 7.6-7.12

- Raw material defects | Machining special operations and practical cases 109

- No wonder Toyota stamping is so good: a day in the life of a Toyota stamping sho

- Analysis on the development trend and demand of China's mold industry

- How many types of sealing rings are there in machinery? What are they used for?

- Hangfa, Hangfa, a scar on the hearts of machine processing workers

- How to mill a large arc surface with a small cutter?

- Dynamics of the processing center of the process! What is the fundamental reason

- 500 ° C ultra -strong aluminum alloy! This problem is overcome

- How much do you know about the hometown of machine tools and molds, how much do

BACK

BACK MT HOME

MT HOME Navbar

Navbar