Three common surface treatment processes for aluminum alloys make the product more textured!

2022.05.10

What are the processing techniques of aluminum alloys

Aluminum alloys are the most widely used non-ferrous metals in the industry, and are widely used in aviation, aerospace, automobile, machinery manufacturing and other industries. Due to its own advantages, aluminum alloys have various processing techniques and can be made into various forms of products. The following will give you a detailed introduction to the processing techniques of aluminum alloys.

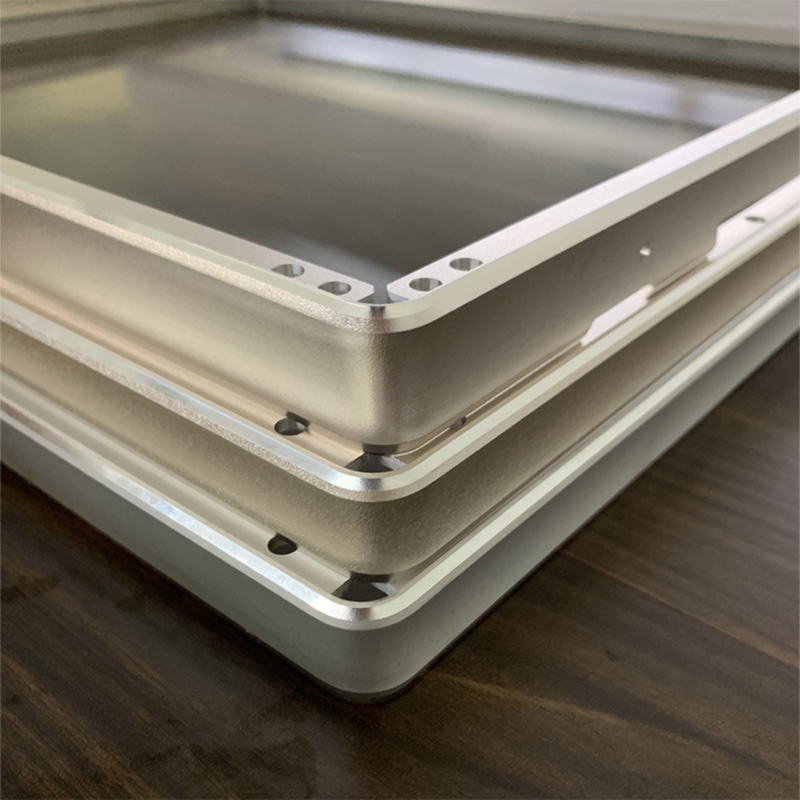

Aluminum alloy sandblasting advertising frame↑

The surface of aluminum alloy can be cleaned and roughened by the impact of high-speed sand flow, which can form different roughness on the surface of aluminum alloy, change the mechanical properties of the surface of the workpiece, and improve the operability of aluminum alloy. TV borders and advertising borders will use this process

polishing process

Polished aluminum alloy TV stand↑

The sandblasting process is to increase the roughness of the aluminum alloy surface, then the polishing process is to reduce the roughness of the aluminum alloy surface and make the surface bright and smooth. This kind of processing can make the aluminum alloy surface close to the stainless steel mirror effect, giving people a simple and fashionable feeling

Drawing process

The lower frame of the TV with brushed surface↑

The wire drawing process is to repeatedly scrape lines on the surface of the aluminum alloy with sandpaper. The lines of the wire drawing are various, and the lines of each fine line can be clearly displayed. The wire drawing process can make the aluminum alloy both fashionable and technological.

High gloss cutting process

The high-gloss cutting process is to use the engraving machine to process local high-brightness areas on the surface of the product. This processing is widely used in various aluminum alloy frames. The high-gloss edge makes the product have more different forms and has a strong sense of fashion.

TV frame after high-gloss cutting ↑

Anodizing process

Two-color oxide aluminum alloy

Anodizing is the electrochemical oxidation of metal or alloy in aluminum alloy processing. Under the corresponding electrolyte and specific process conditions, the aluminum alloy forms an oxide film on the aluminum product due to the action of the applied current.

Anodizing can not only solve the shortcomings of aluminum surface hardness and wear resistance, but also prolong the service life of aluminum and enhance the aesthetics. It has become an indispensable part of aluminum surface treatment and is currently widely used and very successful. .

Previous:How to choose a sheet metal bending die?

Next:14 Operating modes of automated logistics sorting systems in one article!

Related Information

- Industry news

- The tap or drill bit breaks in the hole, how to fix it?

- Why do airplanes use rivets instead of welding?

- Why are engineering drawings all blueprints?

- How is a ping pong ball made? It turns out that it is made of two pieces of plas

- What to do if quality is abnormal? Doing these 3 things well is the key!

- Weekly News 9.7-9.13

- Huawei's three-fold screen is approaching, and the domestic supply chain is wait

- Innovative application of digital twin technology in integrated die-casting prod

- 5 types of carbide cutting tools, what are the differences? Save this article an

- Global manufacturing PMI in June was 49.5% | Weekly News 7.6-7.12

- Raw material defects | Machining special operations and practical cases 109

- No wonder Toyota stamping is so good: a day in the life of a Toyota stamping sho

- Analysis on the development trend and demand of China's mold industry

- How many types of sealing rings are there in machinery? What are they used for?

- Hangfa, Hangfa, a scar on the hearts of machine processing workers

- How to mill a large arc surface with a small cutter?

- Dynamics of the processing center of the process! What is the fundamental reason

- 500 ° C ultra -strong aluminum alloy! This problem is overcome

- How much do you know about the hometown of machine tools and molds, how much do

BACK

BACK MT HOME

MT HOME Navbar

Navbar