The relationship between dimensional tolerances, geometric tolerances, and surface roughness values is too valuable

2021.08.18

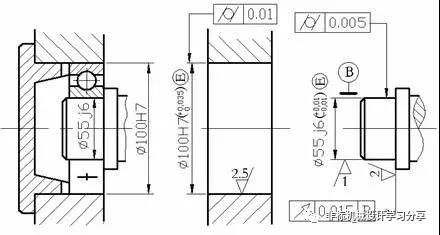

1. The relationship between dimensional tolerances, geometric tolerances, and surface roughness values:

1) Numerical relationship between shape tolerance and dimensional tolerance

When the dimensional tolerance accuracy is determined, the shape tolerance has an appropriate value, that is, generally about 50% of the dimensional tolerance value is used as the shape tolerance value; about 20% of the dimensional tolerance value in the instrument industry is used as the shape tolerance value; heavy industry Approximately 70% of the dimensional tolerance value is used as the shape tolerance value. This shows that. The higher the dimensional tolerance accuracy, the smaller the proportion of the shape tolerance in the dimensional tolerance. Therefore, when designing the size and shape tolerance requirements, except for special circumstances, when the dimensional accuracy is determined, the 50% dimensional tolerance value is generally used as the shape tolerance value. , Which is not only good for manufacturing but also good for ensuring quality.

2) Numerical relationship between shape tolerance and position tolerance

There is also a certain relationship between shape tolerance and position tolerance. From the perspective of the cause of the error, the shape error is caused by machine tool vibration, tool vibration, spindle runout, etc.; while the position error is caused by the non-parallelism of the machine tool rails, the non-parallel or non-perpendicular tool clamping, and the effect of clamping force. As a result, from the definition of tolerance zone, the position error includes the shape error of the measured surface. For example, the parallelism error contains the flatness error, so the position error is much larger than the shape error. Therefore, under normal circumstances, when there is no further requirement, the position tolerance is given, and the shape tolerance is no longer given. When there are special requirements, the shape and position tolerance requirements can be marked at the same time, but the marked shape tolerance value should be less than the marked position tolerance value, otherwise, the parts cannot be manufactured according to the design requirements during production.

3)The relationship between shape tolerance and surface roughness

Although there is no direct connection between shape error and surface roughness in numerical and measurement, there is a certain proportional relationship between the two under certain processing conditions. According to experimental research, in general accuracy, the surface roughness accounts for the shape tolerance 1/5 to 1/4 of. It can be seen that in order to ensure the shape tolerance, the maximum allowable value of the corresponding surface roughness height parameter should be appropriately limited.

Under normal circumstances, the tolerance values among dimensional tolerances, shape tolerances, position tolerances, and surface roughness have the following relationship: dimensional tolerance>position tolerance>shape tolerance>surface roughness height parameter

It is not difficult to see from the numerical relationship between size, shape and position and surface roughness that the numerical relationship of the three should be coordinated during design, and the tolerance value should be marked on the drawing: the roughness value of the given same surface should be less than Its shape tolerance value; and its shape tolerance value should be less than its position tolerance value; each position difference value should be less than its size tolerance value. Otherwise, it will bring all kinds of troubles to manufacturing. However, the most involved in the design work is how to deal with the relationship between dimensional tolerances and surface roughness and the relationship between various matching accuracy and surface roughness.

Under normal circumstances, it is determined according to the following relationship:

1) When the shape tolerance is 60% of the dimensional tolerance (medium relative geometric accuracy), Ra≤0.05IT;

2)When the shape tolerance is 40% of the dimensional tolerance (high relative geometric accuracy), Ra≤0.025IT;

3)When the shape tolerance is 25% of the dimensional tolerance (high relative geometric accuracy), Ra≤0.012IT;

4)When the shape tolerance is less than 25% of the dimensional tolerance (super high relative geometric accuracy), Ra≤0.15Tf (shape tolerance value).

The simplest reference value: the dimensional tolerance is 3-4 times the roughness, which is the most economical.

2. The choice of shape and position tolerance

1) Selection of form and position tolerance items

The functions of comprehensive control items should be fully utilized to reduce the geometric tolerance items and corresponding geometric error detection items given on the drawings.

Under the premise of meeting the functional requirements, items that are easy to measure should be selected. For example, the coaxiality tolerance is often replaced by radial runout tolerance or radial runout tolerance. However, it should be noted that radial runout is a combination of concentricity error and cylindrical shape error, so when replacing, the runout tolerance value given should be slightly larger than the concentricity tolerance value, otherwise it will be too strict.

2)Selection of tolerance principles

According to the functional requirements of the measured elements, the tolerance function and the feasibility and economy of adopting the tolerance principle should be fully exerted.

The principle of independence is used in occasions where there is a big difference between dimensional accuracy and form and position accuracy requirements, and the requirements must be met separately, or the two are not related to ensure movement accuracy, tightness, and no tolerances.

Inclusive requirements are mainly used in occasions that require strict assurance of the nature of cooperation.

The maximum entity requirement is used for the central element, and is generally used in occasions where the accessory requirement is assembleability (no requirement for matching properties).

The minimum entity requirement is mainly used in occasions where the strength of the part and the minimum wall thickness need to be guaranteed.

The combination of the reversible requirement and the maximum (minimum) entity requirement can make full use of the tolerance zone, expand the actual size range of the measured element, and improve the efficiency. It can be selected under the premise of not affecting the performance.

3)Selection of benchmark elements

Selection of reference parts

(1) Select the joint surface of the part positioned in the machine as the reference part. For example, the bottom plane and side of the box, the axis of disc parts, the supporting journal or supporting hole of rotating parts, etc.

(2) The reference element should have sufficient size and rigidity to ensure stable and reliable positioning. For example, using two or more axes that are far apart to form a common reference axis is more stable than one reference axis.

(3) Choose the more precise surface as the reference part.

(4) Try to make the assembly, processing and testing standards uniform. In this way, the errors caused by the inconsistent reference can be eliminated; the design and manufacture of fixtures and measuring tools can also be simplified, and the measurement is convenient.

Determination of the benchmark quantity

Generally speaking, the number of datums should be determined according to the orientation and positioning geometric function requirements of the tolerance items. Orientation tolerances mostly require only one datum, while positioning tolerances require one or more datums. For example, for parallelism, perpendicularity, and coaxiality tolerance items, generally only one plane or one axis is used as the reference element; for position tolerance items, if you need to determine the position accuracy of the hole system, you may need two or three Benchmark elements.

Base order arrangement

When selecting two or more reference elements, the order of the reference elements must be clarified and written in the tolerance box in the first, second, and third order. The first reference element is the main one, and the second reference element is the second. .

Selection of shape and position tolerance value

The general principle: Under the premise of satisfying the function of the part, select the most economical tolerance value.

◆According to the functional requirements of the parts, considering the economy of processing and the structure and rigidity of the parts, the tolerance values of the elements are determined according to the table. And consider the following factors:

◆The shape tolerance given by the same element should be less than the position tolerance value;

◆The shape tolerance value of cylindrical parts (except the straightness of the axis) should be less than its dimensional tolerance value; if it is on the same plane, the flatness tolerance value should be less than the parallelism tolerance value of the plane to the datum.

◆The parallelism tolerance value should be less than the corresponding distance tolerance value.

◆The approximate proportional relationship between surface roughness and shape tolerance: Generally, the Ra value of surface roughness can be taken as the value of shape tolerance (20%~25%).

◆For the following situations, taking into account the difficulty of processing and the influence of other factors besides the main parameters, when meeting the requirements of the function of the part, the selection of 1 to 2 is appropriately reduced:

○The hole is relative to the shaft;

○Slim and larger shafts and holes; shafts and holes with larger distance;

○The surface of parts with large width (more than 1/2 length);

○Tolerance of parallelism and perpendicularity of line-to-line and line-to-face relative to face-to-face.

Provisions for shape and position without tolerance

In order to simplify the drawing, the shape and position accuracy that can be guaranteed by the general machine tool processing, there is no need to indicate the shape and position tolerance on the drawing, and the shape and position without tolerance shall be implemented in accordance with the provisions of GB/T1184-1996. The general content is as follows:

(1) Three tolerance levels of H, K, L are specified for straightness, flatness, perpendicularity, symmetry, and circular runout that are not marked.

(2) The uninjected roundness tolerance value is equal to the diameter tolerance value, but cannot be greater than the uninjected tolerance value of radial circle runout.

(3) The tolerance value of non-inscribed cylindricity is not specified, and it is controlled by the injection or non-injection tolerance of the roundness tolerance, the straightness of the element line and the parallelism of the relative element line.

(4) The unmarked parallelism tolerance value is equal to the larger of the dimensional tolerance between the measured element and the reference element and the unmarked tolerance value of the measured element shape tolerance (straightness or flatness), and take two The longer of the elements serves as the benchmark.

(5) The tolerance value of coaxiality is not specified. If necessary, the unmarked tolerance value of coaxiality can be equal to the unmarked tolerance of circle runout.

(6) The tolerance values of uninjected line profile, surface profile, inclination, and position degree are all controlled by the injection or uninjected linear dimensional tolerance or angle tolerance of each element.

(7) The total runout tolerance value is not specified.

Graphic representation of the shape and position without tolerance value

If the unmarked tolerance value specified in GB/T1184-1996 is used, the standard and grade code should be noted in the title bar or technical requirements. : "GB/T1184-K". is not marked "tolerance principle according to GB/T 4249" working tolerance on the drawing, it should be implemented according to the requirements of "GB/T 1800.2-1998".

Previous:Summary and explanation of basic knowledge points related to hole processing

Next:What kind of turning tool can be used as a fine turning tool?

Related Information

- Industry news

- The tap or drill bit breaks in the hole, how to fix it?

- Why do airplanes use rivets instead of welding?

- Why are engineering drawings all blueprints?

- How is a ping pong ball made? It turns out that it is made of two pieces of plas

- What to do if quality is abnormal? Doing these 3 things well is the key!

- Weekly News 9.7-9.13

- Huawei's three-fold screen is approaching, and the domestic supply chain is wait

- Innovative application of digital twin technology in integrated die-casting prod

- 5 types of carbide cutting tools, what are the differences? Save this article an

- Global manufacturing PMI in June was 49.5% | Weekly News 7.6-7.12

- Raw material defects | Machining special operations and practical cases 109

- No wonder Toyota stamping is so good: a day in the life of a Toyota stamping sho

- Analysis on the development trend and demand of China's mold industry

- How many types of sealing rings are there in machinery? What are they used for?

- Hangfa, Hangfa, a scar on the hearts of machine processing workers

- How to mill a large arc surface with a small cutter?

- Dynamics of the processing center of the process! What is the fundamental reason

- 500 ° C ultra -strong aluminum alloy! This problem is overcome

- How much do you know about the hometown of machine tools and molds, how much do

BACK

BACK MT HOME

MT HOME Navbar

Navbar