What kind of turning tool can be used as a fine turning tool?

2021.08.17

We always say that rough and fine turning should be separated. Rough turning tools are used for rough turning, and fine turning tools are used for fine turning. Rough turning generally requires strong and durable tools, while fine turning tools generally require more. With the popularity of machine clamp tools, we can choose different blades for different processing, but for welding tools, we still need to use sharpening. Today, we will mainly discuss how to use welding tools for finishing.

We know that the purpose of fine turning is to obtain a good finish and ensure the dimensional accuracy of the machining. Therefore, the precision turning tool should always have a sharp edge, capable of micro-cutting and high-speed cutting. The surface of each edge of the fine turning tool should have a higher finish. When choosing the geometric angle of the fine turning tool, pay attention to the relationship between the angles, and it cannot be viewed separately.

The following introduces several commonly used precision turning tools, including welding tools and organic clamping tools.

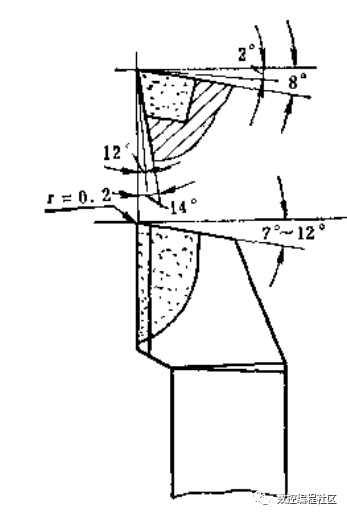

1. High-speed welding turning tool with small rake angle

The blade material is YT30, the rake angle is 2 during cutting, and the welding rake angle of the shank is 8°. This is to consider reducing the amount of sharpening of the turning tool and matching with the blade inclination angle -5° to control the flow of chips to the surface to be machined. The clearance angle is 12°, which reduces the arc radius of the cutting edge and reduces the friction between the back of the turning tool and the workpiece. The smoothness of the front and rear blades is relatively high.

Cutting rate: v=100~150m/min; s=0,08mm/revolution; t=0.05~0.5mm. If a smaller feed amount s=0.02 mm/revolution is used, the main and auxiliary clearance angles can be increased to 16°, and the auxiliary deflection angle can be reduced to 2°~4°. The arc radius is not ground at the tool tip, and the blade inclination angle is 0°. A good surface quality can be achieved.

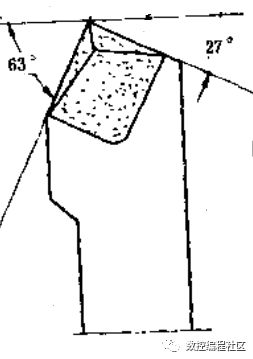

2. Hardened steel welding turning tool

The blade material is YT30, and the main and secondary cutting edges adopt a negative rake angle of -8°, so that a convex peak is formed at the intersection of the main and secondary cutting edges in front of the turning tool, which improves the strength of the cutting edge and can withstand greater pressure. . The main and auxiliary clearance angles are both 3°, the blade inclination angle is +5°, and the blade inclination angle of the auxiliary blade is +3° to enhance the strength of the cutter head. The main deflection angle is 63°, the secondary deflection angle is 27°, and the tool nose radius is 1 to 2 mm. When the rigidity of the lathe or the workpiece is poor, the tool nose radius can be smaller.

Cutting rate v=27m/min; s=0.08~0.1mm/revolution; t=0.03~0.5mm. Suitable for processing hardened steel parts. When processing, it is easy to produce whistling, which can be eliminated by the damping tool bar.

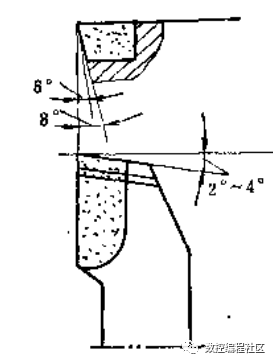

3. Mirror welding turning tool

The blade material is YG6X or YA6, and the blade inclination angle is -10°, so that the chips can be discharged smoothly. The use of 6° of relief angle and 3° of secondary relief angle can reduce vibration and make the back slightly squeeze the workpiece. The size of the entering angle has little effect on the finish. According to the processing requirements, 45°, 60°, 75°, and 90° can be selected. The secondary deflection angle is 2~4° to reduce the residual area.

This turning tool can replace the diamond turning tool. Cutting amount n=600~1000 revolutions/min; s=0.02 mm/revolution; t=0.2~0.3 mm. It is suitable for processing copper materials on precision lathes or instrument lathes. But when this kind of fine turning tool is used, the requirements on the machine tool are higher.

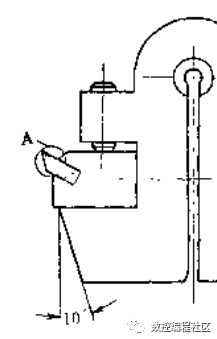

4. Low-speed flat-blade large-cutting machine plus turning tool

The blade material is YT15 or YW, and the rake angle is 25°. As a machine clamp, the blade can be a standard blade or simple sharpening. The sharpening requirements: the rear angle is sharpened at 35° and the installation will form a 10° job For the relief angle, a double relief angle of 0°~4° is ground at 1 mm near the main blade to prevent vibration and knife sticking. The spring cutter bar of the rotatable cutter head is used to adjust the blade inclination to control the outflow direction of the chips, so that the cutting is stable.

The cutting amount adopts low speed n=12-14 rpm; S=8-14 mm/revolution; t=0.02-0.05 mm. Use vulcanized cutting oil as cooling lubricant. When the turning tool is installed, the cutting edge should be about 0.2~0.5mm lower than the working center to increase the working clearance angle, and when the force is unbalanced during the cutting process, the cutting edge will move down due to the elastic action of the tool bar. , Will not cause piercing.

With the advancement of tool technology and the introduction of advanced foreign tools, there are more and more styles of precision turning tools, and their performance is getting better and better. However, as a more economical and commonly used welding tool in processing, it is necessary to have a certain understanding .

Next:Balance method of pump axial force

Related Information

- Industry news

- The tap or drill bit breaks in the hole, how to fix it?

- Why do airplanes use rivets instead of welding?

- Why are engineering drawings all blueprints?

- How is a ping pong ball made? It turns out that it is made of two pieces of plas

- What to do if quality is abnormal? Doing these 3 things well is the key!

- Weekly News 9.7-9.13

- Huawei's three-fold screen is approaching, and the domestic supply chain is wait

- Innovative application of digital twin technology in integrated die-casting prod

- 5 types of carbide cutting tools, what are the differences? Save this article an

- Global manufacturing PMI in June was 49.5% | Weekly News 7.6-7.12

- Raw material defects | Machining special operations and practical cases 109

- No wonder Toyota stamping is so good: a day in the life of a Toyota stamping sho

- Analysis on the development trend and demand of China's mold industry

- How many types of sealing rings are there in machinery? What are they used for?

- Hangfa, Hangfa, a scar on the hearts of machine processing workers

- How to mill a large arc surface with a small cutter?

- Dynamics of the processing center of the process! What is the fundamental reason

- 500 ° C ultra -strong aluminum alloy! This problem is overcome

- How much do you know about the hometown of machine tools and molds, how much do

BACK

BACK MT HOME

MT HOME Navbar

Navbar