Why is the tool intentionally passivated? Ten years of teachers do not necessarily understand!

2021.07.14

The CNC tool used in machining center is not the faster the better, why passivation treatment? In fact, tool passivation is not a literal meaning, but a way to improve tool life.

The quality of the cutting tool can be improved by leveling, polishing and deburring. This is actually a normal process after finishing and before coating.

What is tool passivation?

By deburring, leveling and polishing the cutting tool, the quality and service life of the cutting tool can be improved. At present, the name of a process after finishing grinding and before coating is not unified at home and abroad, such as "edge passivation", "edge strengthening", "edge honing", "edge preparation" or "Er (edge radiation) treatment".

Why tool passivation?

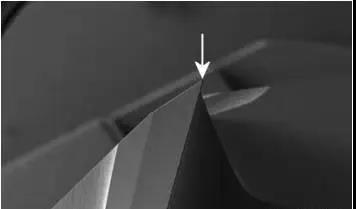

There are micro notches (micro chipping and sawing) in the cutting edge after grinding with ordinary grinding wheel or diamond grinding wheel. In the cutting process, the micro notch of the cutting edge is easy to expand, which speeds up the tool wear and damage.

Modern high-speed machining and automatic machine tools put forward higher requirements for tool performance and stability, especially the coated tool must be passivated before coating, so as to ensure the firmness and service life of the coating.

Purpose of tool passivation

The purpose of edge passivation technology is to solve the defect of micro notch of tool edge after grinding, reduce or eliminate the edge value, and achieve the purpose of smooth, sharp and durable.

Main effects of tool passivation

Edge rounding: deburring the edge to achieve accurate and consistent rounding.

The burr of the edge causes the tool to wear, and the surface of the workpiece will become rough. After passivation, the edge becomes very smooth, which greatly reduces the edge breakage, and the surface finish of the workpiece will be improved.

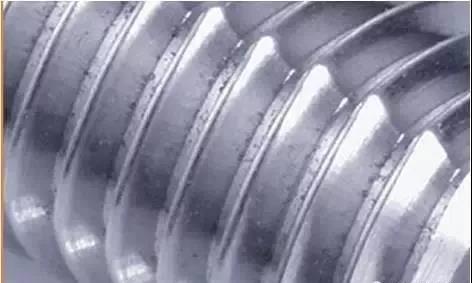

Polishing treatment of the slotting

The surface quality and cutting performance are improved by polishing the groove evenly.

The smoother the groove surface is, the better chip removal is, and the higher cutting speed can be achieved. At the same time, with the improvement of surface quality, the risk of tool and material biting is reduced. And can reduce 40% of the cutting force, cutting more smoothly.

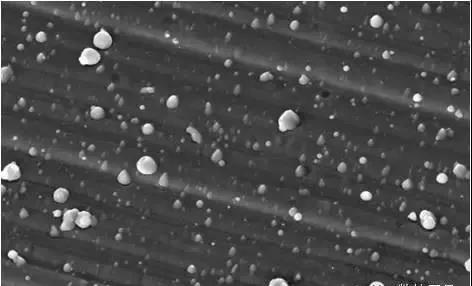

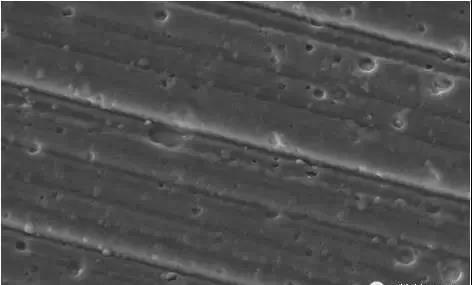

Polishing of coatings

After removing the tool coating, the protruding droplets can improve the surface finish and increase the adsorption of lubricating oil.

After coating, the tool surface will produce some tiny protruding droplets, which improves the surface roughness and makes the tool easy to produce greater friction heat in the cutting process, reducing the cutting speed. After passivation and polishing, the droplets are removed and many small holes are left. More cutting fluid can be absorbed during machining, which greatly reduces the heat generated during machining and greatly improves the cutting speed.

Welcome to visit our Alibaba

https://dgmtwj.en.alibaba.com/?spm=a2700.7756200.0.0.622571d2XUN8qD

Previous:How to tighten flange bolts is scientifically standardized? do you know?

Next:The harm of cutting fluid to human body must not be ignored!

Related Information

- Industry news

- The tap or drill bit breaks in the hole, how to fix it?

- Why do airplanes use rivets instead of welding?

- Why are engineering drawings all blueprints?

- How is a ping pong ball made? It turns out that it is made of two pieces of plas

- What to do if quality is abnormal? Doing these 3 things well is the key!

- Weekly News 9.7-9.13

- Huawei's three-fold screen is approaching, and the domestic supply chain is wait

- Innovative application of digital twin technology in integrated die-casting prod

- 5 types of carbide cutting tools, what are the differences? Save this article an

- Global manufacturing PMI in June was 49.5% | Weekly News 7.6-7.12

- Raw material defects | Machining special operations and practical cases 109

- No wonder Toyota stamping is so good: a day in the life of a Toyota stamping sho

- Analysis on the development trend and demand of China's mold industry

- How many types of sealing rings are there in machinery? What are they used for?

- Hangfa, Hangfa, a scar on the hearts of machine processing workers

- How to mill a large arc surface with a small cutter?

- Dynamics of the processing center of the process! What is the fundamental reason

- 500 ° C ultra -strong aluminum alloy! This problem is overcome

- How much do you know about the hometown of machine tools and molds, how much do

BACK

BACK MT HOME

MT HOME Navbar

Navbar