Does the machine tool have a headache? Master teaches you these 3 tricks

2021.04.26

Nowadays, it is becoming more and more difficult to make products in the machinery industry, the tolerance requirements are getting stricter, and the requirements for surface roughness are getting higher and higher. Master teaches you a few tricks!

If it is processed like this

The product is basically scrapped...

Shaking knives like this...

Most people have only seen it once...

Then, then he was gone...

However, we often say that it is not difficult to solve the problem, but to analyze it correctly and find the right method. Therefore, the experience of shaking the knife taught us by the master is particularly important:

Three elements reconcile each other

The cooperation of fixtures, tools and programs determines the processing effect. For example, if a long tool is used, then our clamping must have better rigidity to make up for it, and the program must also be set accordingly for the long tool.

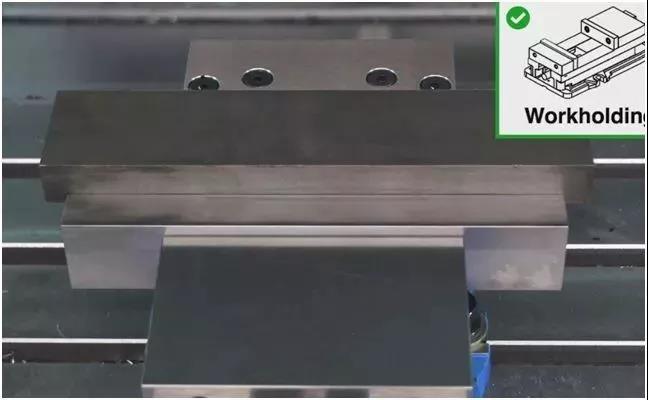

For example, if the overhang is too long during clamping:

Then it will really bounce:

In this case, we need a larger vise to support, and the most important thing is to ensure that the workpiece is placed in the center.

Prefer short tools

In the case of meeting the processing requirements, the shorter the tool set, the better. But don't get caught in the blade!

Like the following, it is best to choose a short handle↓↓↓

There are also milling cutters with unequal distances, like this ↓↓↓

Can avoid resonance! ! !

More modern processing path

If the machining situation does not allow us to improve our own tools, for example, we must use long tools for deep cavity machining, then we have to use the modern tool path on the left of the following figure:

↓↓↓The effect is remarkable when processing↓↓↓

Previous:Calculation of cutting parameters and symbols used in turning

Next:The Germans' understanding of quality is streamlined and just the point!

Related Information

- Industry news

- The tap or drill bit breaks in the hole, how to fix it?

- Why do airplanes use rivets instead of welding?

- Why are engineering drawings all blueprints?

- How is a ping pong ball made? It turns out that it is made of two pieces of plas

- What to do if quality is abnormal? Doing these 3 things well is the key!

- Weekly News 9.7-9.13

- Huawei's three-fold screen is approaching, and the domestic supply chain is wait

- Innovative application of digital twin technology in integrated die-casting prod

- 5 types of carbide cutting tools, what are the differences? Save this article an

- Global manufacturing PMI in June was 49.5% | Weekly News 7.6-7.12

- Raw material defects | Machining special operations and practical cases 109

- No wonder Toyota stamping is so good: a day in the life of a Toyota stamping sho

- Analysis on the development trend and demand of China's mold industry

- How many types of sealing rings are there in machinery? What are they used for?

- Hangfa, Hangfa, a scar on the hearts of machine processing workers

- How to mill a large arc surface with a small cutter?

- Dynamics of the processing center of the process! What is the fundamental reason

- 500 ° C ultra -strong aluminum alloy! This problem is overcome

- How much do you know about the hometown of machine tools and molds, how much do

BACK

BACK MT HOME

MT HOME Navbar

Navbar