Opportunities and Challenges that China's Intelligent Manufacturing facing

2020.11.05

Intelligent manufacturing is a human-machine integrated intelligent system composed of intelligent machines and human experts. It can perform intelligent activities during the manufacturing process, such as analysis, reasoning, judgment, conception, and decision-making. Through the cooperation of humans and intelligent machines, to expand, extend and partially replace the mental work of human experts in the manufacturing process. It updates the concept of manufacturing automation and extends it to flexibility, intelligence and high integration.

At present, intelligent manufacturing has become the main direction of our country's construction of a manufacturing power. Accelerating the development of intelligent manufacturing is the only way to promote high-quality development of Chinese manufacturing and form new advantages in international competition. Chinese manufacturing companies must use digital transformation to enhance product innovation and management capabilities, improve quality and efficiency, and gain a competitive advantage.

Chinese smart manufacturing has obvious advantages and huge market development space

During the COVID-19 pandemic in 2020, many smart manufacturing companies demonstrated their "intelligent manufacturing" capabilities. In the face of restrictions on residents' travel, companies' resumption of work, and medical staff shortages, some smart manufacturing companies rely on technological accumulation and manufacturing advantages to launch meal delivery drones, automatic temperature measurement robots, and smart medical service robots to help the epidemic Life underneath works.

Smart manufacturing companies are ushering in a "high-light moment", from which we can see the huge development potential of Chinese smart manufacturing. According to the "2016-2020 China Intelligent Manufacturing Industry In-depth Investigation and Investment Prospect Forecast Report" released by China Investment Consultants, our country's intelligent manufacturing industry will grow at a compound annual growth rate of about 20% by 2020, and the output value is expected to exceed 3 trillion yuan.

At the same time, our country's manufacturing industry has gone through the development stages of mechanization, automation, and digitalization, and has built a complete manufacturing system and manufacturing infrastructure, which has an important position in the global industrial chain. This gives China the possibility and basic strength to realize intelligent manufacturing and promote the transformation of the global industrial chain.

Intelligent manufacturing promotes enterprise transformation and upgrading

The accelerated integration of advanced manufacturing technologies has made the design, production, management, and service links of the manufacturing industry increasingly intelligent. Intelligent manufacturing is leading the value of the entire process of manufacturing enterprises. In summary, smart manufacturing can promote enterprise transformation and upgrading from at least the following three aspects.

1. Smart design

Refers to the application of intelligent design methods and advanced design information systems (CAX, networked collaborative design, design knowledge base, etc.) to support the intelligent promotion and optimized operation of all links in the enterprise product development and design process. For example, in practice, modeling and simulation have been widely used in product design, and the time for new products to enter the market has been greatly reduced.

2. Smart products

In the field of smart products, Internet technology, artificial intelligence, and digital technology are embedded in traditional product designs, making products gradually become Internet-based smart terminals. For example, sensors, memories, transmitters, processors, and other equipment are incorporated into products to produce The product has dynamic storage, communication and analysis capabilities, so that the product has the characteristics of traceability, traceability, and location. At the same time, it can also extensively collect individual consumer needs for innovative product design, making smart products more market dynamic .

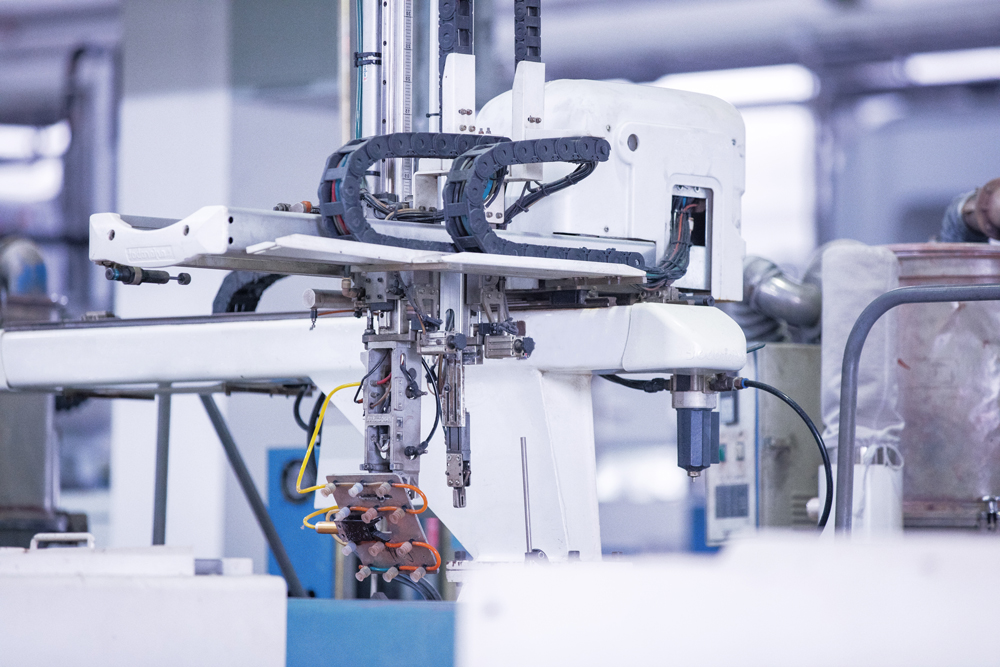

3. Intelligent equipment

Industrial production equipment under the intelligent manufacturing mode needs to be integrated and fused with information technology and artificial intelligence technology, so that traditional production equipment has the ability to perceive, learn, analyze and execute. In the process of equipment intelligence transformation, production enterprises can start from two aspects: stand-alone intelligence or stand-alone equipment interconnection to form an intelligent production line or intelligent workshop. However, it is worth noting that simply making production equipment intelligent cannot be regarded as equipment intelligence in the true sense. Only when market and consumer needs are integrated into equipment upgrades and transformations can it be regarded as the real realization of equipment intelligence throughout the industry chain.

Previous:Quality is not tested out! How to do a good job in quality management?

Next:Don't forget the process industry to build a smart factory

Related Information

- Industry news

- The tap or drill bit breaks in the hole, how to fix it?

- Why do airplanes use rivets instead of welding?

- Why are engineering drawings all blueprints?

- How is a ping pong ball made? It turns out that it is made of two pieces of plas

- What to do if quality is abnormal? Doing these 3 things well is the key!

- Weekly News 9.7-9.13

- Huawei's three-fold screen is approaching, and the domestic supply chain is wait

- Innovative application of digital twin technology in integrated die-casting prod

- 5 types of carbide cutting tools, what are the differences? Save this article an

- Global manufacturing PMI in June was 49.5% | Weekly News 7.6-7.12

- Raw material defects | Machining special operations and practical cases 109

- No wonder Toyota stamping is so good: a day in the life of a Toyota stamping sho

- Analysis on the development trend and demand of China's mold industry

- How many types of sealing rings are there in machinery? What are they used for?

- Hangfa, Hangfa, a scar on the hearts of machine processing workers

- How to mill a large arc surface with a small cutter?

- Dynamics of the processing center of the process! What is the fundamental reason

- 500 ° C ultra -strong aluminum alloy! This problem is overcome

- How much do you know about the hometown of machine tools and molds, how much do

BACK

BACK MT HOME

MT HOME Navbar

Navbar