Raw material defects | Mechanical processing characteristic operation and practical case

2024.03.14

Section 1 raw material defect category

1. Case 3: Aluminum Fracture

Material: 7A04-T6 aluminum stick.

Faculture background: During the use of a model of a model, aluminum fracture and falling off during the use of the development phase causes the problem of product failure.

Invasion characteristics:

-

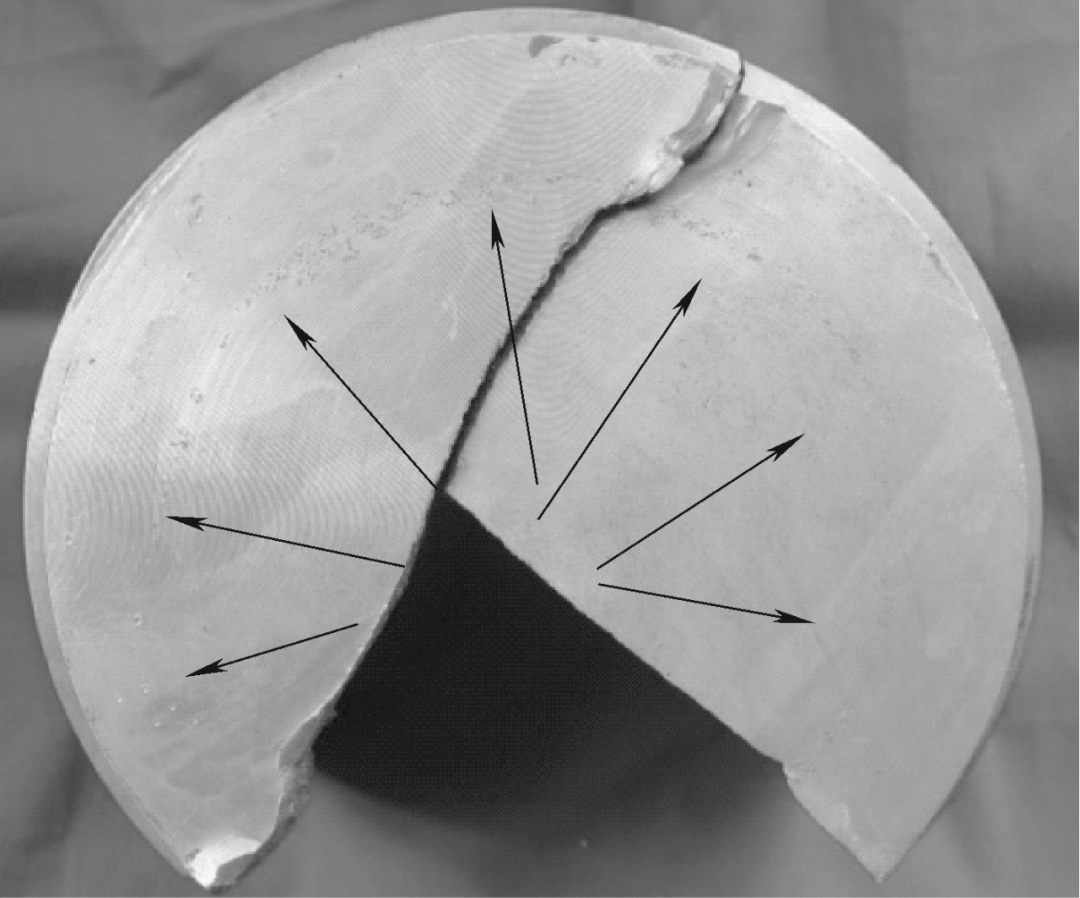

The shape of the fragments of aluminum pieces, as shown in Figure 5-8.

Recycling aluminum remnants form

-

It is found that there is a ring-shaped and continuous distribution at the bottom surface of the aluminum part, as shown in Figure 5-9.

-

A total of crack sources were found on the broken surface of the two aluminum pieces. The extension direction is an axis of the aluminum parts, and the length penetrates the entire aluminum part. The linen of a ring-shaped and continuous distribution in Figure 5-9 is actually exposed to defective tissue; And aerobic spinach is mixed, and its color is shown in Figure 5-10, which is darker than the surrounding area.

Figure 5-10 The biggest crack source

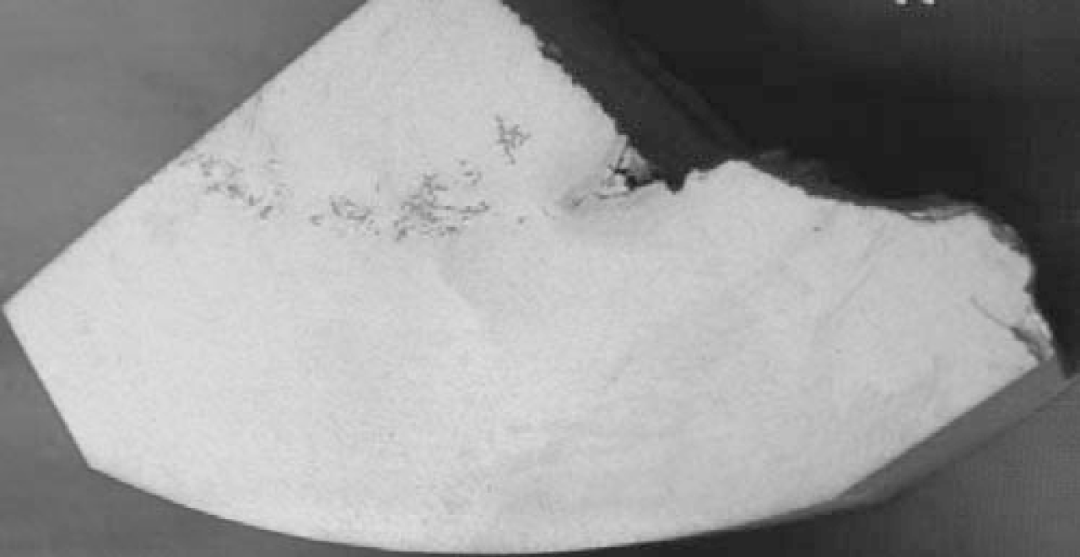

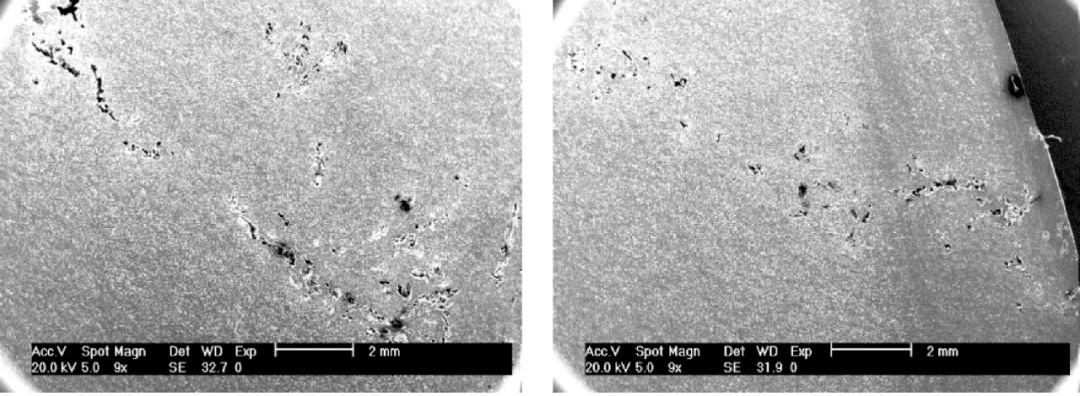

Cut a low-twice sample in the center of the maximum crack source, as shown in Figure 5-11, after corrosion, the arc band flawed belt is shown in Figure 5-12; The situation is shown in Figures 5-13 and Figure 5-14.

Figure 5-11 Sittage of Low-magnalor Simage Sample

Figure 5-12 The surface state after the sample corrodes

Failure mode: Crispy break.

The cause of failure: The raw material (aluminum alloy rod material) itself has serious tail contraction defects that causes aluminum crispy to break.

Correction measures: Add the detection process before the feeding.

Figure 5-13 Lower amplification multiple Mirror image diagram of each part of each part

For inquiry and quotation of CNC custom service, please contact :

Phone /Wechat/Whatsapp: +86 13612776575

E-mail:sales03@dgmtwj.cn

Previous:What is the difference between chrome -plated, nickel -plated and galvanized?

Next:Why does the German work 6 hours a day, the manufacturing industry is still strong?

Related Information

- Industry news

- The tap or drill bit breaks in the hole, how to fix it?

- Why do airplanes use rivets instead of welding?

- Why are engineering drawings all blueprints?

- How is a ping pong ball made? It turns out that it is made of two pieces of plas

- What to do if quality is abnormal? Doing these 3 things well is the key!

- Weekly News 9.7-9.13

- Huawei's three-fold screen is approaching, and the domestic supply chain is wait

- Innovative application of digital twin technology in integrated die-casting prod

- 5 types of carbide cutting tools, what are the differences? Save this article an

- Global manufacturing PMI in June was 49.5% | Weekly News 7.6-7.12

- Raw material defects | Machining special operations and practical cases 109

- No wonder Toyota stamping is so good: a day in the life of a Toyota stamping sho

- Analysis on the development trend and demand of China's mold industry

- How many types of sealing rings are there in machinery? What are they used for?

- Hangfa, Hangfa, a scar on the hearts of machine processing workers

- How to mill a large arc surface with a small cutter?

- Dynamics of the processing center of the process! What is the fundamental reason

- 500 ° C ultra -strong aluminum alloy! This problem is overcome

- How much do you know about the hometown of machine tools and molds, how much do

BACK

BACK MT HOME

MT HOME Navbar

Navbar