The differences and misunderstandings of high -strength bolts and ordinary bolts

2024.02.22

High -strength bolts are the most common construction content in steel structure construction. All steel structure engineers will feel that they are no longer familiar.

However, this may not be the case. Today, we start with the most basic concept and take you to re -understand high -strength bolts, which may subvert your most basic understanding.

01 What is high -strength bolt

High-Stringth FricTion Grip Bolt, English literally translates: high-strength friction pre-bolt, English abbreviation: HSFG. The full name of high -strength bolt is called high -strength bolt connection. Generally, it is generally not abbreviated as high -strength bolts.

It can be seen that the high -intensity bolts mentioned in our Chinese construction are the abbreviation of high -strength friction pre -bolts. In daily communication, the words "friction" and "gRIP" "are simply briefly tormented, which has caused many engineering and technical personnel to understand the basic definition of high -strength bolts and have misunderstandings.

Misunderstanding 1: The bolt with a material level of more than 8.8 is "high -intensity bolt"?

The core difference between high -intensity bolts and ordinary bolts is not in the strength of the use of materials, but in the form of force. The essence is whether to exert a pre -tightening force and use the static friction to resist shear.

In fact, in the British standard specification, the high-strength bolts (HSFG Bolt) mentioned in the US standard specifications are only 8.8 and 10.9 levels (BS EN 14399 / ASTM-A325 & ASTM-490), but the ordinary bolts include 4.6, which contains 4.6. 5.6, 8.8, 10.9, 12.9 et al. (BS 3692 11 tables 2); from this, it can be seen that the strength of the material is not the key to the difference between high -strength bolts and ordinary bolts.

02 Where is the "Gao Qiang" correctly?

According to GB50017, a single ordinary bolt (Class B) level 8.8 and high -intensity bolt 8.8 levels of tensile and shear strength are calculated.

By calculating, we can see that under the same level, the design values of the tensile strength and shear strength of ordinary bolts are higher than high -strength bolts.

So where is the high -strength bolt, "strong"?

In order to answer this question, it is necessary to start with the design of the two bolts, study the law of bullet plastic deformation, and understand the limit state when designing destruction.

Ordinary bolt and high -strength bolt working state under work stress strain curve

The extreme state when designing destruction

Ordinary bolt: The screw itself exceeds the plastic deformation allowed by the design, and the screw is cut.

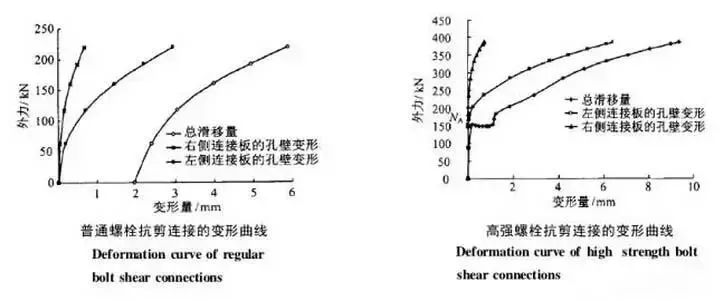

Ordinary bolt connections will start with a relatively slippery panel between the front connection board, and then the bolt rod is in contact with the connecting plate.

High -intensity bolt: The static friction between the effective friction surface is overcome, and the two steel plates have relative displacement. The design considerations are damaged.

High -strength bolt connection, the friction force is first affected by the shear force. When the load increases to the friction force is not enough to resist the shear force, the static rubbing force is overcome, and the connection board is relatively slippery (limit state). However, although it is destroyed at this time, the bolt rod is in contact with the connecting board, and it can still use its own bullet plastic deformation to withstand shear power.

Misunderstanding 2: The carrying capacity of high -strength bolts is higher than that of ordinary bolts, for "high strength"?

It can be seen from the calculation of a single bolt that the design intensity of high -strength bolt -up resistance and shear resistance is lower than that of ordinary bolts. The essence of its high strength is: when working normally, nodes do not allow any relative slip, that is,: the bullet plastic deformation is small, and the node has a large rigidity.

It can be seen: In the case of a given design node load, nodes designed with high -strength bolts do not necessarily save bolts, but their deformation, large rigidity, and high safety reserves. Suitable for the position with a large rigidity of the node in accordance with the main beam, which is in line with the basic seismic design principle of "strong node, weak rod".

The strength of high -intensity bolts is not the design value of its own load capacity, but it is manifested in its design node, high, high safety performance, and strong ability to resist destruction.

03 The difference between ordinary bolts and high -strength bolts

Ordinary bolts can be reused,High -strength bolts cannot be reused.

High -strength bolts are generally made of high -strength steel (No. 45 steel (8.8s), 20mmTib (10.9s). It is a prestressed bolt. The friction type uses a torque wrench to apply a prescribed prestress, and the pressure type is twisted.Ordinary bolts are generally made of ordinary steel (Q235), just tightened.

Ordinary bolts are generally level 4.4, level 4.8, level 5.6 and 8.8.

High -strength bolts are generally 8.8 and 10.9, of which 10.9 are mostly.

For inquiry and quotation of CNC custom service, please contact :

Phone /Wechat/Whatsapp: +86 13612776575

E-mail:sales03@dgmtwj.cn

Previous:Why does the German work 6 hours a day, the manufacturing industry is still strong?

Next:Mechanical engineers must master the theoretical knowledge

Related Information

- Industry news

- The tap or drill bit breaks in the hole, how to fix it?

- Why do airplanes use rivets instead of welding?

- Why are engineering drawings all blueprints?

- How is a ping pong ball made? It turns out that it is made of two pieces of plas

- What to do if quality is abnormal? Doing these 3 things well is the key!

- Weekly News 9.7-9.13

- Huawei's three-fold screen is approaching, and the domestic supply chain is wait

- Innovative application of digital twin technology in integrated die-casting prod

- 5 types of carbide cutting tools, what are the differences? Save this article an

- Global manufacturing PMI in June was 49.5% | Weekly News 7.6-7.12

- Raw material defects | Machining special operations and practical cases 109

- No wonder Toyota stamping is so good: a day in the life of a Toyota stamping sho

- Analysis on the development trend and demand of China's mold industry

- How many types of sealing rings are there in machinery? What are they used for?

- Hangfa, Hangfa, a scar on the hearts of machine processing workers

- How to mill a large arc surface with a small cutter?

- Dynamics of the processing center of the process! What is the fundamental reason

- 500 ° C ultra -strong aluminum alloy! This problem is overcome

- How much do you know about the hometown of machine tools and molds, how much do

BACK

BACK MT HOME

MT HOME Navbar

Navbar