Common defects and preventive measures in carburizing and quenching

2023.03.03

Guide

Crystal carburizing quenching is actually a composite process, that is, carburizing+quenching. We are always used to connecting the two, because the two processes are completed on the same equipment that are most commonly encountered in production, but there are also carburizing air -cooled cold, carbonate slowly cold, and then re -heating the quenching process, secondary time, secondary time Exercise process). Then some of the adverse phenomena encountered in production are some problems of carburizing, some are quenching problems, and some are the result of the comprehensive impact of carburizing quenching.

We know that all thermal treatment processes are inseparable from three core issues: heating, insulation, and cooling. Including the heating temperature, heating speed, thermal insulation time, cooling speed, of course, there are atmosphere problems. So once there is a problem, we will habitually analyze the reasons from these aspects.

Crystal carburizing quenching often detects these indicators: product surface appearance, surface hardness, heart hardness, depth of carburizing layer, (effective hardening layer, deep hardening depth) gold phase tissue and deformation. Let's share the views from these indicators below.

1 appearance problem

1. Oxidation skin: This is mainly because the equipment is leaking, impure, or water -containing, and it needs to be found from the equipment and raw supplementary materials.

2. Another most headache is the problem of pigmentation. This is also a challenging new requirement proposed by heat treatment in modern times. The reasons are intricate and very profound.

2 Hardness is unqualified

1. High hardness (no discussion)

2. Low hardness: divided into two cases, one is unqualified in carburizing. The reason may be that the carburizing layer is shallow and does not meet the requirements of the drawing (carburizing is not penetrated) or the selected detection ruler is overcarring with a carburizing layer to withstand the carburizing layer to penetrate.

Solution: Replenishment, detection ruler according to. JBT 6050-2006 "Steel Parts Thermal Treatment Hardness Testing Plum" is actually a function of temperature, time, and carbon potential. Judging from the above elements, it is possible to consider the method of increasing heating temperature, extending the heat insulation time, and increasing carburizing and carbon. (Of course, the adjustment of each parameter must fully combine its own equipment and product requirements.) It may also be because the existence of non -horse organizations on the surface will also occur.

Low hardness will also occur in another situation, that is, the carburizing is qualified, but the quenching is not qualified. This situation is the most complicated. As the saying goes: heat treatment is heated by three points, and seven points depend on cooling. It also reflects the position of the cooling process in the heat treatment process. The following is a comparison test I designed. Everyone can discuss the effects of cooling on hardness. Take 3 sets of different materials but the size of the specifications are exactly the same. The size is φ20mmx100mm. (We say that No. 20 steel test rod is No. 1, 20CR test rod to No. 2, 20CRMNTI as the 3rd test bar) The trial rod is used to complete the carburizing with the same process in the same furnace. Assume that the depth of the three test rod carburizing layers is 0.6-0.7mm (PS: assuming it is only established in an ideal state). Please think about the following conditions:

a. Relaxation of quenching under the same conditions.

b. The quenching medium is slow, fast oil, water, saline.

c. Do not stir in the same medium and stir with strong stirring and quenching.

After completing the carburizing, group A uses 800 ° C quenching, and group B uses 860 ° C quenching. What is the order of their hardness from high to low? How to sort the hardening layer (with 550HV1.0 as the boundary) from deep to shallow? Take the two test rods of the same material, which group can get higher quenching hardness and effective hardening depth? Whether the results of the above test can be concluded that the depth of the carburizing layer is not the same as the depth of the effective sclerosis layer, the actual hardening layer depth is affected by material quenchability, quenching temperature, and cooling speed. The cooling characteristics of the cooling medium also affect the quenching effect. Of course, the size effect of the parts also affects the harder effect.

3. Unemployment of hardness: The furnace temperature is uniform (affecting the uniformity of carburizing), the equipment structure, the atmosphere circulation, the amount of furnace, (affecting the uniformity of the peak layer, and affecting the uniformity of quenching).

4. The core hardness is unqualified.

Highly high: The quenching temperature is high, the material is too good, the upper limit of the carbon and alloy ingredients, and the medium cooling speed is too fast.

Low hardness: It is just the opposite.

Example sharing: No. 20 steel 1.5mm products, requirements: lying layer 0.2-0.4mm core HV250, some friends who think of the requirements are unreasonable, (everyone should know that the maximum hardness of the 20 steel bars macaronia will be at HV450 at HV450 -470) To solve this problem, we must first know the characteristics of this material: including quenchability and hardness. Then combined with the major factors mentioned above the effects of quenching effect, find ways to heal and cool down. In this case, the materials are fixed. We can think of the method from quenching temperature and cooling speed. This manufacturer just uses super speed oil. If the quenching intensity cannot meet the requirements, we can also think from the reduction of quenching temperature. Method. When the temperature is reduced to a certain degree, the chills of the cold Olympic Ainer will precipitate a certain amount of ferrite. At this time, the hardness will decrease, the more the temperature will be reduced. The more, the more hardness decreases. Here is a reminder that it is necessary to fully combine the existing conditions of the equipment and the special favorable indicator of the shallow peak layer.

3 The penetration layer or the effect of the effect of the effect of the effect of the effect of the deeper and shallow

As mentioned earlier, the depth of the infiltration layer is a comprehensive function of temperature, time, and carbon concentration. In order to solve this problem, you have to start with the heating temperature, heating speed, thermal insulation time, cooling speed, and controlling the carbon concentration gradient in the carbon layer. The higher the temperature, the longer the time, and the higher the carbon potential, the deeper, and vice versa. But in fact, it is far more than that. To design a carburizing process, you must comprehensively consider equipment, furnace volume, oil characteristics, gold phase tissue, material quenchability, carbon concentration gradient and cooling speed in the carburizing layer. There are many factors. This can be analyzed with a low hardness of the previous hardness and no longer explained in depth.

4 gold phase organization

Matrier exceeds the standard: The grains of raw materials are thick, or the temperature is too high, and the carburizing temperature is too high.

Solution: Positive fire or multiple times of fire, (It is recommended that the temperature of the positive fire higher than the carburizing temperature 20-30 ° C). If possible, consider the cold and cooling of the carburizing.

Olympic Olympics exceeds the standard: The quenching temperature is too high, and the amount of carbon content in the austenitic is too high (too high in carbon potential).

Solution: Fully diffuse, conditions allow the quenching temperature, recovery high temperature recovery, re -heating quenching, or deep cold treatment.

Carbides exceeded standards: The austenite contains too much carbon content (too high carbon potential), and the cooling process is too slow.

Solution: Fully diffuse, control cooling speed, reduce carburizing and quench temperature differences in conditions, and use low temperature or quenching of Asian temperature as much as possible. If you must use this process, you must control the amount of furnace. Everyone thinks about it: Similarly, the device uses 920 ° C for 820 ° C for quenching. The amount of furnace is 1000kg and 600kg. Is the cooling speed the same? Which time does it take? Which carbides are higher?

5 non -horse and oxidation

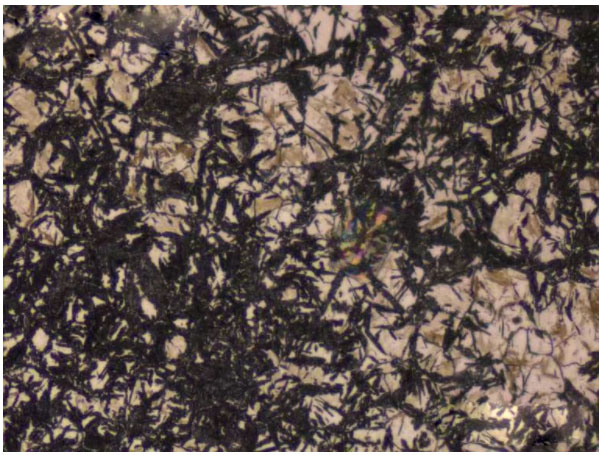

Internal oxidation: It is the response of alloy elements such as chromium and manganese molybdenum in the steel (mainly oxygen, water, and carbon dioxide) in the atmosphere, which causes the alloy element in the matrix to poverty and cause the material to quench. Under a microscope, a black mesh tissue can be seen, and its essence is the poverty alloy element in the substrate.

The solution is to find a way to improve the medium cooling speed, enhance the hardening intensity of quenching, and reduce the oxidized atmosphere in the furnace (to ensure the purity of the raw and auxiliary materials of the carburizing, minimize the amount of balance of the air, control the balanced air content, ensure that the equipment does not leak air, and the equipment does not leak air, and the equipment does not leak air, and the equipment does not leak air. It is difficult to eliminate conventional equipment. It is said that low -voltage vacuum carburizing equipment can be completely eliminated. Because it has not been exposed to it, it is not easy to express opinions. In addition, a strong spray can also reduce the internal oxidation level. See the point of view of some experts, and some believe that excessive ammonia in the co -seepage of carbon and nitrogen can also produce serious non -horses. Some foreign machinery industries attach great importance to internal oxidation, especially the gear industry. Generally, it is generally required that its depth is not greater than 0.02mm.

Non -horses: After quenching the carburizing layer is caused by the problem of quenching or quenching problems, non -Matima tissues appear on the surface, such as: Ichinophyll, asbone, and of course, and of course, it also includes an internal oxidation type. Its mechanism is similar to internal oxidation, and the solution is similar.

6 Deformation problem

This is a systematic problem, and it is also the most headache for staff who are engaged in hot treatment. It is guaranteed from several aspects of raw material process cooling medium. The above content is only a talk with personal experience. If there is no rigorous feature, please correct me, thank you.

Previous:Hot treatment and tensile strength

Next:What does public threads and US -British thread letters and numbers mean?

Related Information

- Industry news

- The tap or drill bit breaks in the hole, how to fix it?

- Why do airplanes use rivets instead of welding?

- Why are engineering drawings all blueprints?

- How is a ping pong ball made? It turns out that it is made of two pieces of plas

- What to do if quality is abnormal? Doing these 3 things well is the key!

- Weekly News 9.7-9.13

- Huawei's three-fold screen is approaching, and the domestic supply chain is wait

- Innovative application of digital twin technology in integrated die-casting prod

- 5 types of carbide cutting tools, what are the differences? Save this article an

- Global manufacturing PMI in June was 49.5% | Weekly News 7.6-7.12

- Raw material defects | Machining special operations and practical cases 109

- No wonder Toyota stamping is so good: a day in the life of a Toyota stamping sho

- Analysis on the development trend and demand of China's mold industry

- How many types of sealing rings are there in machinery? What are they used for?

- Hangfa, Hangfa, a scar on the hearts of machine processing workers

- How to mill a large arc surface with a small cutter?

- Dynamics of the processing center of the process! What is the fundamental reason

- 500 ° C ultra -strong aluminum alloy! This problem is overcome

- How much do you know about the hometown of machine tools and molds, how much do

BACK

BACK MT HOME

MT HOME Navbar

Navbar