Reference System and Angle of Drill Bit

2022.12.06

Drilling is the only method (machining) for machining holes from solids. The tools used are mainly fried dough twist drills, as well as flat drills, deep hole drills, center drills, group drills, etc.

The machining accuracy is IT13 ~ IT10, Ra=20 ~ 10 μ m.

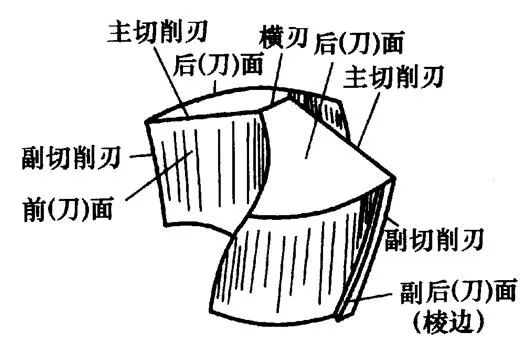

1.Structure of drill bit

The coordinate planes of each reference coordinate system of turning tool angle can be used on drill bits.

Front face: spiral face of spiral groove

Main cutting edge: two intersecting lines between the main rear cutter face and the spiral groove

Auxiliary cutting edge: two intersecting lines of edge and spiral groove

Horizontal edge: the intersection line of two rear tool faces at the drill center

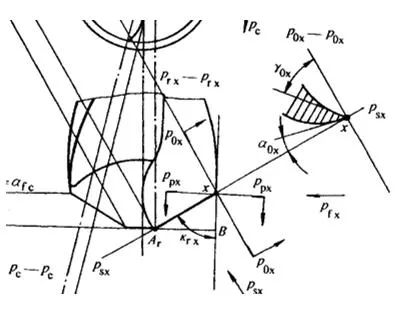

In addition, due to the particularity of the bit structure, three measuring planes are specified, namely

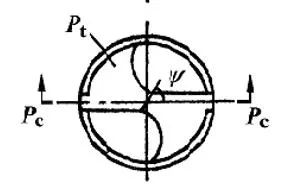

End plane: the projection plane of the end face perpendicular to the drill axis. (Pt)

Mid section: the plane passing through the drill axis and parallel to the two main cutting edges. (Pc)

Column section: the cylindrical surface formed by making a straight line parallel to the drill axis through a selected point on the main cutting edge, and the straight line rotates around the drill axis. (Pz)

2. Angle of drill bit

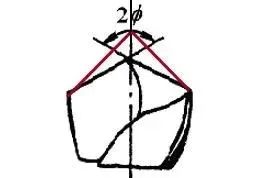

(1) Apex angle

The included angle of two main cutting edges in the projection of the middle plane

Decreasing the apex angle can increase the cutting edge length, reduce the load on the cutting edge per unit length, reduce the axial force, improve the axial stability of the drill bit, and improve the tool tip strength and heat dissipation conditions. However, if the tip angle is too small, the strength of the drill point will be reduced, the chip will curl seriously, and the torque will increase, which is not conducive to chip removal.

The top angle of standard fried dough twist drill is 20=116 °~118 °.

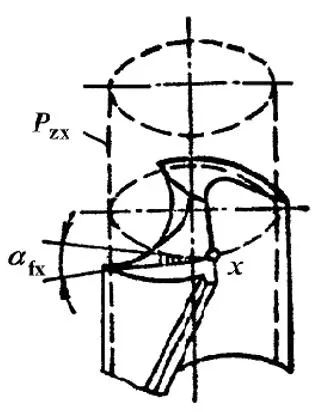

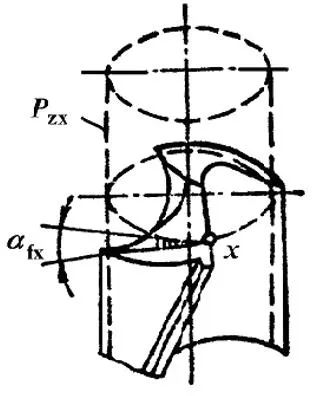

(2) Posterior horn

The back angle of the drill bit is the included angle between the back tool face and the end plane measured in the cylindrical surface through a selected point x on the main cutting edge

The back angle of a standard fried dough twist drill increases from 8~14 to 20 °~27 ° from the outer edge to the center. The back angle of the cutting edge refers to the back angle of the outermost edge of the cutting edge. For a large diameter drill, take a smaller value, and for a small diameter drill, take a larger value.

(3) Transverse edge bevel

The oblique angle of the transverse edge is the angle between the transverse edge and the middle plane measured in the end plane. After the back corner of the fried dough twist drill is grinded, the oblique angle of the horizontal edge will naturally form. 50 °~55 ° for standard fried dough twist drill

(4) Anterior horn

Since the rake face is helical, the rake angle on the main cutting edge varies from 30 ° to - 30 ° from the outer edge of the drill to the drill core

Next:Master copper and its welding with different materials

Related Information

- Industry news

- The tap or drill bit breaks in the hole, how to fix it?

- Why do airplanes use rivets instead of welding?

- Why are engineering drawings all blueprints?

- How is a ping pong ball made? It turns out that it is made of two pieces of plas

- What to do if quality is abnormal? Doing these 3 things well is the key!

- Weekly News 9.7-9.13

- Huawei's three-fold screen is approaching, and the domestic supply chain is wait

- Innovative application of digital twin technology in integrated die-casting prod

- 5 types of carbide cutting tools, what are the differences? Save this article an

- Global manufacturing PMI in June was 49.5% | Weekly News 7.6-7.12

- Raw material defects | Machining special operations and practical cases 109

- No wonder Toyota stamping is so good: a day in the life of a Toyota stamping sho

- Analysis on the development trend and demand of China's mold industry

- How many types of sealing rings are there in machinery? What are they used for?

- Hangfa, Hangfa, a scar on the hearts of machine processing workers

- How to mill a large arc surface with a small cutter?

- Dynamics of the processing center of the process! What is the fundamental reason

- 500 ° C ultra -strong aluminum alloy! This problem is overcome

- How much do you know about the hometown of machine tools and molds, how much do

BACK

BACK MT HOME

MT HOME Navbar

Navbar