The diagnosis and disposal of the bearing installation are not installed

2022.10.12

Rolling bearing is very common in early failure caused by bad bearings caused by adverse bearing. This article introduces the bad inspection, diagnosis and response method of the bearings.

Basic types of bearing to medium bad

The bearing to the adverseness of the bearing usually refers to the case where the axis of the inner ring and the outer ring in the lower bearing inner ring and the outer ring of the bearing state after the bearing is installed.

For a single bearing, there is a certain angle between the inner ring of the bearing and the axis of the bearing room, which is the wrong medium of a single bearing.

For the general dual -branch shaft system, the two support point connection should be a shaft, and the connection of the center point of the two bearing room should also be a shaft. If the two axes present the angle, the axis we say is not right in the middle Essence

In a shaft system, if the inner and outer circle axis of a support point (bearing) is good, and another bearing angle is presented, the bearing of the bad bearing will be easily invalidable. It will also be indirectly affected for good bearing.

In a bearing system, if the two support points (bearing) itself are good, and the connection between the center point of the two support points is not good, then the two bearing will be directly affected by the badness of the middle. The additional load appears inside the bearing, which will shorten the bearing life.

Many materials are not summarized by the bearing into the bearing to the middle bad and the bearing room. Among them, the boring of the axis is the situation where the two fulcrum connection between the above two fulcrum is incorrectly in the case; This situation is often related to the processing accuracy of components.

The above is the bad in the axis system. When one shaft is connected to the other, two shafts are not good. If the two axes have a certain angle, the angle is wrong. If the two axes are parallel to each other, but not on a straight line, it is not right in parallel.

Bearing inspection of bad Chinese

For the middle situation of the two axis connections, the medium level can be used directly to the medium measurement. No repeated here.

For a situation on a bearing, if there is a bad in the bearing after installation, the basic inspection methods include: measurement inspection, vibration examination, bearing marks analysis and other methods.

Measurement

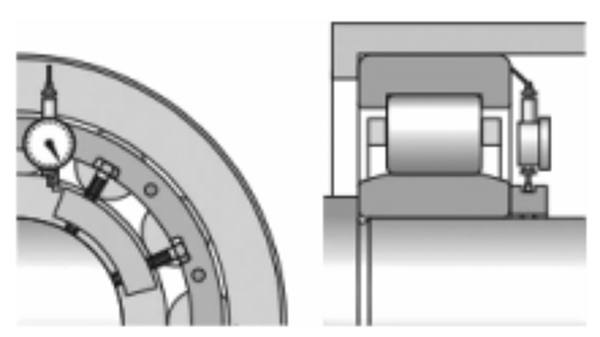

After the bearing is installed, you can check it as shown below.

The figure uses a cylindrical roller bearings as an example. In fact, this method is also applicable to other types of bearings. The specific operation is to rotate a circle along the end surface with thousands of tables, measure the maximum minimum value difference, and then change it to a non -middle angle.

Vibration

Vibration analysis is performed when the bearing is running. The method of frequency domain analysis is usually used to develop Fourier on the medium vibration signal. When the rotating axis is not good, the two times frequency will have a large amplitude value. When this amplitude exceeds half of the frequency (frequency conversion) amplitude, it means that the non -gear condition must be corrected.

There are also some differences in the characteristics of various bad vibrations. You can refer to the corresponding vibration analysis literature, or the relevant content of the book "Motor Bearing Fault Diagnosis and Analysis", which is not repeated here.

Bearing trace analysis

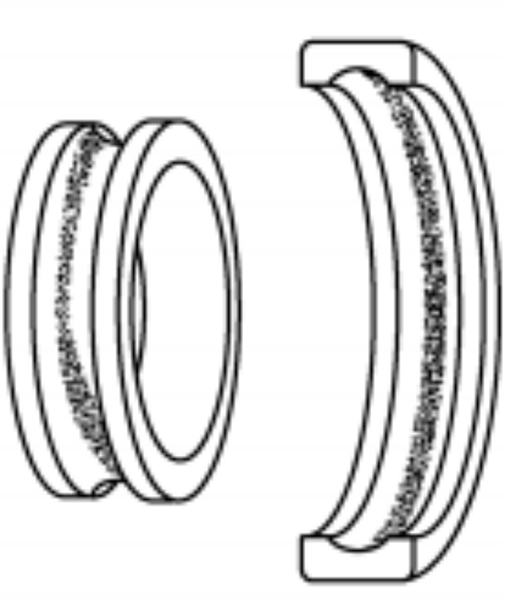

The running bearing generally leaves a trajectory in the rolling road. By identifying the characteristics of the connection trajectory, you can determine whether there is a bad situation.

The picture below shows the traces of the neutralizes when the bearing room is eccentric.

The picture below is the traces of the middle of the bias when the axis is eccentric.

Bearing measures for bad response to China

The existence of the bearing will bring an additional additional load to the bearing to the bearing. The bearings will fail early, so it must be processed and corrected. Specific measures include:

l Check the shape and position accuracy of the relevant parts. If the shape position accuracy is caused by the processing problem of parts processing, it is necessary to re -process and strictly control the position accuracy. For specific control requirements, please refer to the "Diagnosis and Analysis of Motor Bearing Faults".

l The bad damage to the installation process. During the installation process, if the bearing and the shaft are mandatory and mandatory, the bearing may be damaged. At this time, we should design the corresponding installation to ensure the simple installation of the operator and ensure the accuracy of the medium.

l In the multi -axis system, if there is a bad situation in the inspection, the situation of the dedicated instrument is needed to adjust and correct the middle situation between the axis.

Previous:The latest fastener standard model control table

Next:Some principles to be considered in sheet metal product design

Related Information

- Industry news

- The tap or drill bit breaks in the hole, how to fix it?

- Why do airplanes use rivets instead of welding?

- Why are engineering drawings all blueprints?

- How is a ping pong ball made? It turns out that it is made of two pieces of plas

- What to do if quality is abnormal? Doing these 3 things well is the key!

- Weekly News 9.7-9.13

- Huawei's three-fold screen is approaching, and the domestic supply chain is wait

- Innovative application of digital twin technology in integrated die-casting prod

- 5 types of carbide cutting tools, what are the differences? Save this article an

- Global manufacturing PMI in June was 49.5% | Weekly News 7.6-7.12

- Raw material defects | Machining special operations and practical cases 109

- No wonder Toyota stamping is so good: a day in the life of a Toyota stamping sho

- Analysis on the development trend and demand of China's mold industry

- How many types of sealing rings are there in machinery? What are they used for?

- Hangfa, Hangfa, a scar on the hearts of machine processing workers

- How to mill a large arc surface with a small cutter?

- Dynamics of the processing center of the process! What is the fundamental reason

- 500 ° C ultra -strong aluminum alloy! This problem is overcome

- How much do you know about the hometown of machine tools and molds, how much do

BACK

BACK MT HOME

MT HOME Navbar

Navbar