Commonly used functions of several gaskets

2022.07.05

There are many kinds of gaskets, different sizes, thicknesses, materials, and different functions. Now the editor will introduce the functions and installation precautions of several commonly used gaskets to you.

Copper skin asbestos pad

Copper skin asbestos pads have the characteristics of high pressure resistance and high temperature resistance, and are used in engine cylinder head gaskets. Before using the copper-skin asbestos pad, it is necessary to remove the dirt or sand on the clean joint surface first. Note that the copper-skin flanging side should face the cylinder head side to prevent reverse air leakage. The copper skin asbestos pad should not be folded hard during storage and installation, and should be kept intact and with sufficient elasticity. If it is found to be damaged or used for too long, it should be replaced in time.

Paper Pad

It has two uses. One is to increase sealing to prevent oil leakage; the other is to adjust the gap between components. The components that use paper pads cannot be increased or decreased at will. For example, the paper pads between each side cover of the diesel pump are used to adjust the oil supply time. The thickness of the gasket is 0.1 mm. Every time the gasket increases or decreases by 0.1 mm, the oil supply angle of the flywheel is corresponding. Change 1.7 degrees. The axial clearance between the crank bush and the crankshaft is also achieved by adjusting the paper pad between the side cover of the flywheel end and the body. If the paper pad is damaged, it should be replaced in time to prevent oil leakage.

Flat pad

Its function is to distribute the pressure of the nut evenly on the pressure-receiving part through the flat washer, and at the same time protect the surface of the bolt thread and the connecting body. Generally, thin metal shells are fixed with metal flat pads.

Aluminum flat pad

Aluminum flat pads have certain toughness, and can be used at the joints of diesel and oil pipelines. Before installing the aluminum flat gasket, check whether there are dents or cracks on the plane, otherwise, air will be sucked into the oil leakage pipe, which will not only cause the waste of oil, affect the power of the engine, but also cause the burning tile to hold the shaft due to insufficient oil supply. Wait for the failure to occur.

Copper flat pad

The material of the copper flat gasket is generally made of red copper, and it is mostly used in parts with high pressure, such as the gasket of the fuel injector.

cork mat

Cork pads have certain toughness and are generally used between the water tank, the engine oil pan and the body. The cork pad has a soft texture and good sealing performance, reducing vibration, collision and wear of parts. The weak point is that it is crunchy and brittle. When making cork pads, you should pay attention to drilling first and then cutting, so that it is not easy to damage. When installing, scrape the joint surface and apply butter on both sides of the cork pad to increase its sealing performance. When tightening the bolts, tighten the fixing bolts evenly and in a diagonal order.

Asbestos mat

Asbestos gasket has the characteristics of high temperature resistance, so the parts using it are high temperature parts, such as between the exhaust pipe and the cylinder head, these parts cannot be replaced by other gaskets.

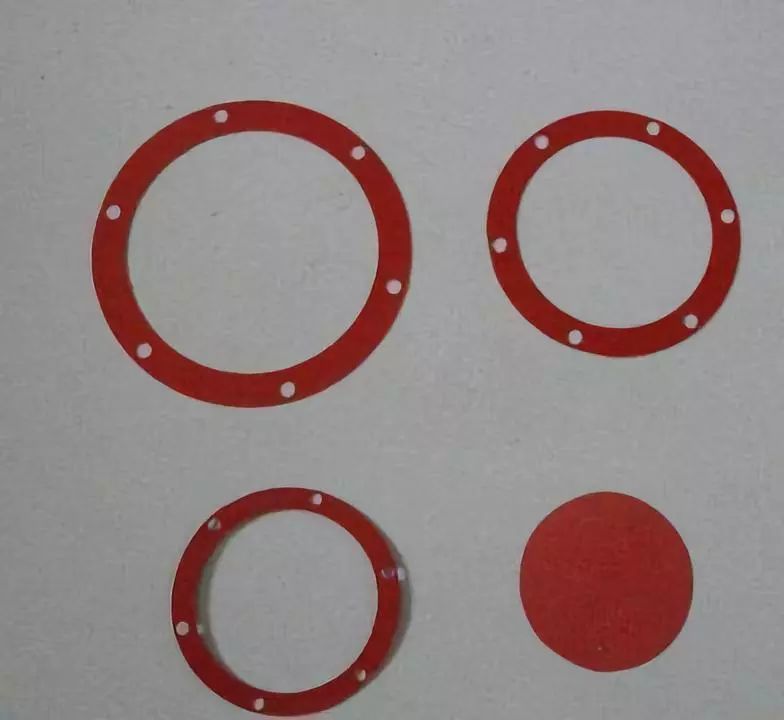

Rubber mat

The rubber gasket is made of two kinds of raw materials, one is a gasket made of non-oil-resistant raw materials for the air-sealing part, such as the gasket used on the air filter housing; the other is a gasket made of oil-resistant raw materials for oil-sealing parts Gaskets, such as the rubber pads on both ends of the diesel oil filter. When using, it should be noted that the oil-resistant rubber pad can replace the non-oil-resistant rubber pad, and the non-oil-resistant rubber pad cannot be used instead of the oil-resistant rubber pad. In the long-term use of the rubber pad, if it is found that it has hardened and lost its elasticity, it should be replaced in time to avoid wear of the parts.

Felt pad

Felt pads have certain wear resistance and shock absorption, and are generally used at the bottom of thin metal boxes or at the clamps, such as the bottom of diesel tanks.

Previous:Technical requirements for common mechanical drawings

Next:Summary of basic knowledge points related to hole processing

Related Information

- Industry news

- The tap or drill bit breaks in the hole, how to fix it?

- Why do airplanes use rivets instead of welding?

- Why are engineering drawings all blueprints?

- How is a ping pong ball made? It turns out that it is made of two pieces of plas

- What to do if quality is abnormal? Doing these 3 things well is the key!

- Weekly News 9.7-9.13

- Huawei's three-fold screen is approaching, and the domestic supply chain is wait

- Innovative application of digital twin technology in integrated die-casting prod

- 5 types of carbide cutting tools, what are the differences? Save this article an

- Global manufacturing PMI in June was 49.5% | Weekly News 7.6-7.12

- Raw material defects | Machining special operations and practical cases 109

- No wonder Toyota stamping is so good: a day in the life of a Toyota stamping sho

- Analysis on the development trend and demand of China's mold industry

- How many types of sealing rings are there in machinery? What are they used for?

- Hangfa, Hangfa, a scar on the hearts of machine processing workers

- How to mill a large arc surface with a small cutter?

- Dynamics of the processing center of the process! What is the fundamental reason

- 500 ° C ultra -strong aluminum alloy! This problem is overcome

- How much do you know about the hometown of machine tools and molds, how much do

BACK

BACK MT HOME

MT HOME Navbar

Navbar