Comparison of the advantages and disadvantages of using aluminum shells for motors

2022.04.27

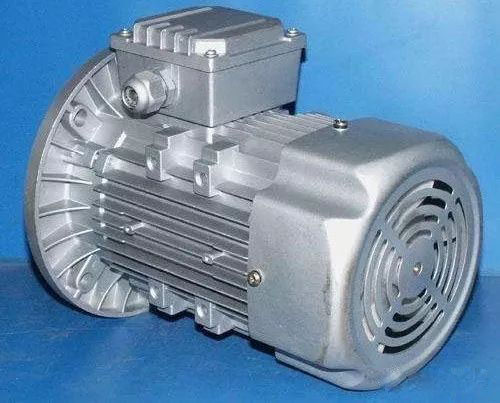

The metal shell of the motor is mainly made of cast iron, steel plate and aluminum. With the pursuit of the aesthetic appearance of the motor, the aluminum shell motor is constantly recognized by the market, but as a motor person, we are very aware of the aluminum shell motor and the cast iron shell. We should evaluate the motor performance, cost, compliance with operating conditions and market acceptance and other aspects.

Motors with a center height of 80 to 200 have both cast iron shells and aluminum shells; motors with a center height of 315 or more have almost no aluminum shells, mainly because the mechanical strength is relatively poor. But the two materials do not have much influence on other properties of the motor. Ms. Shen made a basic classification of the differences between the two and shared them with you.

The difference between cast iron and aluminum shell

(1) The density of aluminum is relatively small, which can reduce the weight of the whole machine. For small-sized motors, the aluminum casing is preferred on the premise of strength compliance. The overall price of the two is basically the same, but the apparent effect of the aluminum casing motor is better.

(2) The cast iron shell is durable, can withstand beating, and has high mechanical strength; compared with the aluminum shell, it is softer, and it is easy to form scars on the surface.

(3) Iron-shell motors are prone to rust, especially in hot weather; however, aluminum-shell motors have poor corrosion resistance.

(4) The heat dissipation coefficient of aluminum is much better than that of cast iron, and the heat dissipation of iron is worse than that of aluminum.

The advantages of aluminum

The mechanical function of pure aluminum itself is not high, but its light weight and good casting fluidity are unmatched by other metals, and aluminum is relatively active and can be organically combined with other metals to become aluminum alloys. Impressively, some sophisticated equipment, such as airplanes and other equipment, takes advantage of this. In fact, most of the aluminum we see is aluminum alloy.

The characteristics of cast iron are that the manufacturing process is very mature, the threshold for entry is low, and the cost is low, but its own defects are only iron-carbon alloys, and compared with aluminum, cast iron is not easy to combine with other metals, which is inherently determined by its own characteristics.

Aluminum is an active metal, and a dense oxide film with a thickness of about 50 angstroms (1 angstrom = 0.1 nanometers) is immediately formed on the surface of aluminum in dry air, so that aluminum will not be further oxidized and resistant to water; but aluminum powder is easily mixed with air. Combustion; molten aluminum can react violently with water; aluminum is amphoteric, easily soluble in strong alkalis, and also soluble in dilute acids. This is a problem that must be considered when choosing an aluminum housing base.

Previous:14 Operating modes of automated logistics sorting systems in one article!

Next:How to play with the size chain

Related Information

- Industry news

- The tap or drill bit breaks in the hole, how to fix it?

- Why do airplanes use rivets instead of welding?

- Why are engineering drawings all blueprints?

- How is a ping pong ball made? It turns out that it is made of two pieces of plas

- What to do if quality is abnormal? Doing these 3 things well is the key!

- Weekly News 9.7-9.13

- Huawei's three-fold screen is approaching, and the domestic supply chain is wait

- Innovative application of digital twin technology in integrated die-casting prod

- 5 types of carbide cutting tools, what are the differences? Save this article an

- Global manufacturing PMI in June was 49.5% | Weekly News 7.6-7.12

- Raw material defects | Machining special operations and practical cases 109

- No wonder Toyota stamping is so good: a day in the life of a Toyota stamping sho

- Analysis on the development trend and demand of China's mold industry

- How many types of sealing rings are there in machinery? What are they used for?

- Hangfa, Hangfa, a scar on the hearts of machine processing workers

- How to mill a large arc surface with a small cutter?

- Dynamics of the processing center of the process! What is the fundamental reason

- 500 ° C ultra -strong aluminum alloy! This problem is overcome

- How much do you know about the hometown of machine tools and molds, how much do

BACK

BACK MT HOME

MT HOME Navbar

Navbar