The method of selecting the positioning datum for machining parts of machining center

2021.11.09

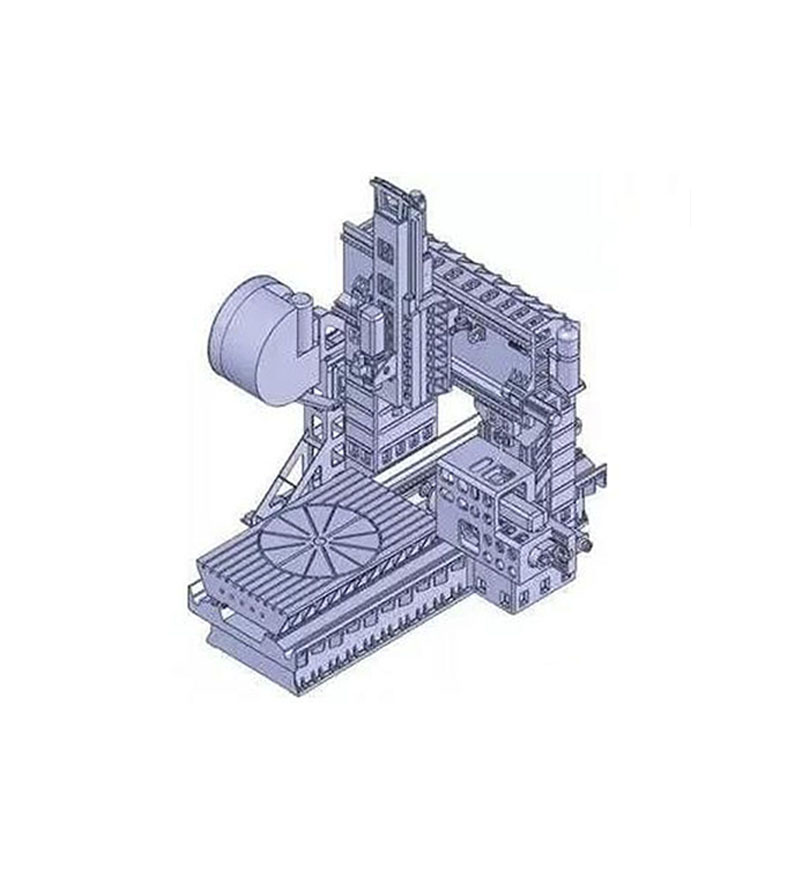

In the process of CNC machining center processing, whether the selection of positioning reference is reasonable or not determines the quality of the parts, whether it can ensure the dimensional accuracy and mutual position accuracy requirements of the parts, and the processing sequence arrangement between the surfaces of the parts. , When using fixtures to install the workpiece, the choice of positioning datum will also affect the complexity of the fixture structure. This requires that the fixture can not only withstand large cutting forces, but also meet the positioning accuracy requirements.

Therefore, the choice of positioning datum is a very important process issue. So how do we choose the positioning datum when machining parts with a CNC machining center? Here is a brief introduction:

1. The selected datum should be able to ensure the accurate positioning of the workpiece, convenient to load and unload the workpiece, can quickly complete the positioning and clamping of the workpiece, the clamping is reliable, and the fixture structure is simple.

2. The selected datum of the CNC machining center and the dimensions of each processing part are simple to calculate, minimize the calculation of the dimensional chain, and avoid or reduce the calculation links and calculation errors.

3. Ensure the accuracy of various processing. When determining the positioning datum of the parts, the following principles should be followed:

(1) The origin of the workpiece coordinate system, that is, the "programming zero point", and the part positioning datum do not necessarily have to coincide, but there must be a definite geometric relationship between the two. The main consideration for the selection of the origin of the workpiece coordinate system is to facilitate programming and measurement. For parts with high dimensional accuracy requirements, when determining the positioning datum, it should be considered whether the coordinate origin of the CNC machining center can be accurately measured by the positioning datum.

(2) When both the processing datum and the processing of each station are completed on the CNC machining center, the selection of the positioning datum needs to consider the completion of as much processing content as possible. For this reason, it is necessary to consider a positioning method that facilitates all surfaces to be processed. For example, for a box, it is best to use a positioning method of two pins on one side to facilitate the processing of other surfaces by the tool.

(3) Try to choose the design datum on the part as the positioning datum. This requires that when roughing, consider what rough datum to use to machine each surface of the fine datum, that is, each positioning datum used on the CNC machining center should be processed in the previous ordinary machine tool or other machine tools, so that it is easy to ensure that each work The precision relationship between the machined surfaces.

(4) When the positioning datum of the CNC machining center parts is difficult to coincide with the design datum, the assembly drawings should be carefully analyzed to determine the design function of the part design datum, and the shape and position between the positioning datum and the design datum shall be strictly specified through the calculation of the dimensional chain. Tolerance range to ensure machining accuracy.

(5) When the station processing including the design datum cannot be completed on the CNC machining center at the same time, the positioning datum and the design datum should be overlapped as much as possible. At the same time, it must be considered that after positioning with this reference, all key precision parts can be processed in one clamping.

Previous:Six steps allow you to become a CNC programmer, how many steps have you taken?

Next:Do you know how to choose the material of the parts after many years of working in machinery?

Related Information

- Industry news

- The tap or drill bit breaks in the hole, how to fix it?

- Why do airplanes use rivets instead of welding?

- Why are engineering drawings all blueprints?

- How is a ping pong ball made? It turns out that it is made of two pieces of plas

- What to do if quality is abnormal? Doing these 3 things well is the key!

- Weekly News 9.7-9.13

- Huawei's three-fold screen is approaching, and the domestic supply chain is wait

- Innovative application of digital twin technology in integrated die-casting prod

- 5 types of carbide cutting tools, what are the differences? Save this article an

- Global manufacturing PMI in June was 49.5% | Weekly News 7.6-7.12

- Raw material defects | Machining special operations and practical cases 109

- No wonder Toyota stamping is so good: a day in the life of a Toyota stamping sho

- Analysis on the development trend and demand of China's mold industry

- How many types of sealing rings are there in machinery? What are they used for?

- Hangfa, Hangfa, a scar on the hearts of machine processing workers

- How to mill a large arc surface with a small cutter?

- Dynamics of the processing center of the process! What is the fundamental reason

- 500 ° C ultra -strong aluminum alloy! This problem is overcome

- How much do you know about the hometown of machine tools and molds, how much do

BACK

BACK MT HOME

MT HOME Navbar

Navbar