The mystery of the hot pulley

2021.08.24

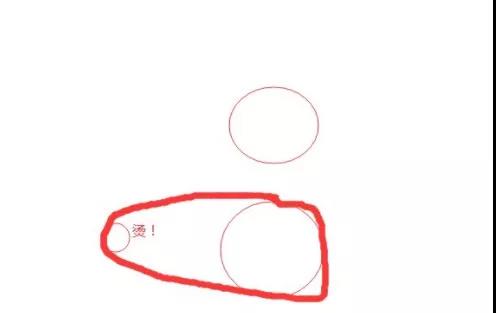

It’s the same belt pulley. Today, the thread was tapped on the belt pulley. The motor shaft is completely impossible to slip, and a large amount of rosin has also been applied to the belt. The remaining reason may be that the belt is not slipping at all. Is the inner diameter of the outer diameter of 50 and the inner diameter of 22 caused by the excessive deformation of the wrap angle and the heat accumulation caused by the fast speed of the small wheel?

If this is the reason, will replacing the toothed belt solve this problem?

In addition, I found that the driving wheel is actually O-shaped, and the A belt is full of dots. If the O belt is installed, will the driven wheel not have enough contact surface? Will the difference of O type and A type cause fever?

The Brain Congress conducted an emergency meeting on site and made several suggestions:

1. Use two o-shaped belts

2. Use two tooth type A

3. Use two o-shaped long straps, use a triangle winding method, and add an empty wheel at a high place to make his wrap angle not so big

4 Use two A-type long straps

As for why there are so many entanglements, is the V-belt grip better than the toothed belt? Does the toothed belt generate less heat than the triangle belt?

Previous:A complete list of CNC tools, some of which you have never used!

Next:Summary and explanation of basic knowledge points related to hole processing

Related Information

- Industry news

- The tap or drill bit breaks in the hole, how to fix it?

- Why do airplanes use rivets instead of welding?

- Why are engineering drawings all blueprints?

- How is a ping pong ball made? It turns out that it is made of two pieces of plas

- What to do if quality is abnormal? Doing these 3 things well is the key!

- Weekly News 9.7-9.13

- Huawei's three-fold screen is approaching, and the domestic supply chain is wait

- Innovative application of digital twin technology in integrated die-casting prod

- 5 types of carbide cutting tools, what are the differences? Save this article an

- Global manufacturing PMI in June was 49.5% | Weekly News 7.6-7.12

- Raw material defects | Machining special operations and practical cases 109

- No wonder Toyota stamping is so good: a day in the life of a Toyota stamping sho

- Analysis on the development trend and demand of China's mold industry

- How many types of sealing rings are there in machinery? What are they used for?

- Hangfa, Hangfa, a scar on the hearts of machine processing workers

- How to mill a large arc surface with a small cutter?

- Dynamics of the processing center of the process! What is the fundamental reason

- 500 ° C ultra -strong aluminum alloy! This problem is overcome

- How much do you know about the hometown of machine tools and molds, how much do

BACK

BACK MT HOME

MT HOME Navbar

Navbar