Never loosen the nut: give you the drawing, you can't make it!

2021.07.26

China's high-speed rail has built the world's largest high-speed rail system and technology platform, leading the world's high-speed rail trend. However, the nuts used on the high-speed railway have to be imported. We can only buy the never loose nuts of hard lock industry Co., Ltd., a Japanese small enterprise with only 45 employees.

Not only China, but also the world's leading countries in science and technology, including Britain, Australia and the United States, have to order small nuts from Japan's hadlock company. There is only one in the world. It can be imagined how much market share of hadlock nuts has made a nut to the extreme.

During the operation of high-speed railway, the high-speed train is in constant contact with the rail, resulting in a very large vibration. In this vibration, ordinary screws will be loosened and fly. If you don't want to be shaken, you need screws and nuts to be tight and never loose.

1. Nuts have changed life

In fact, as early as 1961, Lin Keyan invented the U nut, a nut that won't rotate.

After he had worked for five years, as an employee of the company, he visited an international industrial product exhibition held in Osaka. He took back a bag of materials and samples from the exhibition. In these materials and samples, an anti rotation nut attracted Ruolin's attention.

It is a nut with stainless steel wire as a clip to prevent loosening. It has complex structure and high price“ Can't it be simple and cheap? " Ruolin began to study hard.

Soon he came up with a method to clamp the screw thread with a leaf spring, and the test product achieved satisfactory results. Ruolin, 28, named the anti rotation nut u nut and founded a company to produce and sell the nut. This is the first company founded by Ruolin - Fuji Precision Manufacturing Institute. It took Ruolin more than an hour to develop the anti rotation nut, but it took more than two years to promote it to the market. With the increase of sales, Ruolin's confidence also increased greatly and advertised "never loose nut".

I didn't expect that this advertisement brought trouble to Ruolin. The U nut assembled on the excavator and pile driver is loose due to too much vibration.

Some customers Sue. At that time, the monthly sales of Fuji precision production office had reached 100 million yen, and loosening was not common. Many people in the company regarded the sentence "never loose nut" as just an advertising word, so they did not take these lawsuits seriously. But if Lin doesn't think so.

He said that since it was publicly stated that such a nut would never loosen, it should be made so that it would not loosen under any conditions. But can you do that? Partners are skeptical. In order to keep his faith, Ruolin left the company he founded.

At the end of 1973, when Ruolin was passing by Zhuji Da she (Zhuji District, Osaka City) near his home, he looked up at the tall memorial archway at the entrance and suddenly flashed the idea that "if you insert that wedge, it won't loosen". He immediately started to hit the "a" in the gap between the nut and the screw, and the result was "right in the heart". Inspired by the familiar shrine, Ruolin said, "this may be the apocalypse."

Ruolin got inspiration from the tenon in ancient wooden structure buildings and invented the nut that never loosens by adding tenon in the nut. In 1974, in order to produce this new non loose nut, Ruolin established a second enterprise from scratch - Hard Lock Industry Co., Ltd. But waiting for him is the same long and painful promotion road as when he started his first business. Because the structure of this hard lock nut is more complex than ordinary nuts and the cost is also high, the sales price is about 30% higher than ordinary nuts. This has become the biggest obstacle to the promotion of this kind of nut.

When hard lock nut had no sales, the new company had to do some other work to maintain the company's operation in addition to the patent fee of u nut. Finally, a railway company adopted Ruolin's products, which proved the strength of never loosening nuts.

Railway companies need shock proof and anti loose nuts very much, and there are many Japanese railway companies, which brings development opportunities to Ruolin's new company. Jr company, Japan's largest railway company, finally adopted hard lock nuts and is fully used in Shinkansen in Japan.

Hard lock nut has become the only nut that never loosens in the world. It is widely used not only in Japan, but also in major bridges and buildings around the world.

2. Wedge and hammer two in one nut

China's high-speed rail has built the world's largest high-speed rail system and technology platform, leading the world's high-speed rail trend. However, the nuts used on the high-speed railway have to be imported. We can only buy the never loose nuts of hard lock industry Co., Ltd., a Japanese small enterprise with only 45 employees.

Not only China, but also the world's leading countries in science and technology, including Britain, Australia and the United States, have to order small nuts from Japan's hadlock company. There is only one in the world. It can be imagined how much market share of hadlock nuts has made a nut to the extreme.

During the operation of high-speed railway, the high-speed train is in constant contact with the rail, resulting in a very large vibration. In this vibration, ordinary screws will be loosened and fly. If you don't want to be shaken, you need screws and nuts to be tight and never loose.

1. Nuts have changed life

In fact, as early as 1961, Lin Keyan invented the U nut, a nut that won't rotate.

After he had worked for five years, as an employee of the company, he visited an international industrial product exhibition held in Osaka. He took back a bag of materials and samples from the exhibition. In these materials and samples, an anti rotation nut attracted Ruolin's attention.

It is a nut with stainless steel wire as a clip to prevent loosening. It has complex structure and high price“ Can't it be simple and cheap? " Ruolin began to study hard.

Soon he came up with a method to clamp the screw thread with a leaf spring, and the test product achieved satisfactory results. Ruolin, 28, named the anti rotation nut u nut and founded a company to produce and sell the nut. This is the first company founded by Ruolin - Fuji Precision Manufacturing Institute. It took Ruolin more than an hour to develop the anti rotation nut, but it took more than two years to promote it to the market. With the increase of sales, Ruolin's confidence also increased greatly and advertised "never loose nut".

I didn't expect that this advertisement brought trouble to Ruolin. The U nut assembled on the excavator and pile driver is loose due to too much vibration.

Some customers Sue. At that time, the monthly sales of Fuji precision production office had reached 100 million yen, and loosening was not common. Many people in the company regarded the sentence "never loose nut" as just an advertising word, so they did not take these lawsuits seriously. But if Lin doesn't think so.

He said that since it was publicly stated that such a nut would never loosen, it should be made so that it would not loosen under any conditions. But can you do that? Partners are skeptical. In order to keep his faith, Ruolin left the company he founded.

At the end of 1973, when Ruolin was passing by Zhuji Da she (Zhuji District, Osaka City) near his home, he looked up at the tall memorial archway at the entrance and suddenly flashed the idea that "if you insert that wedge, it won't loosen". He immediately started to hit the "a" in the gap between the nut and the screw, and the result was "right in the heart". Inspired by the familiar shrine, Ruolin said, "this may be the apocalypse."

Ruolin got inspiration from the tenon in ancient wooden structure buildings and invented the nut that never loosens by adding tenon in the nut. In 1974, in order to produce this new non loose nut, Ruolin established a second enterprise from scratch - Hard Lock Industry Co., Ltd. But waiting for him is the same long and painful promotion road as when he started his first business. Because the structure of this hard lock nut is more complex than ordinary nuts and the cost is also high, the sales price is about 30% higher than ordinary nuts. This has become the biggest obstacle to the promotion of this kind of nut.

When hard lock nut had no sales, the new company had to do some other work to maintain the company's operation in addition to the patent fee of u nut. Finally, a railway company adopted Ruolin's products, which proved the strength of never loosening nuts.

Railway companies need shock proof and anti loose nuts very much, and there are many Japanese railway companies, which brings development opportunities to Ruolin's new company. Jr company, Japan's largest railway company, finally adopted hard lock nuts and is fully used in Shinkansen in Japan.

Hard lock nut has become the only nut that never loosens in the world. It is widely used not only in Japan, but also in major bridges and buildings around the world.

2. Wedge and hammer two in one nut

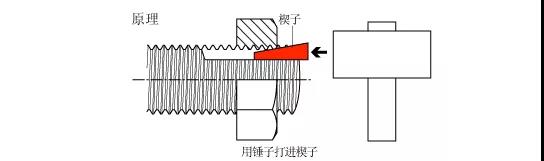

The concept of "hard lock nut" is very simple, that is, a wedge is inserted between the nut and the screw to prevent loosening( Fig. 1) however, it is neither efficient nor realistic to insert wedges one by one into the nuts to be used at the construction site. How can the wedge function? Ruolin thought hard.

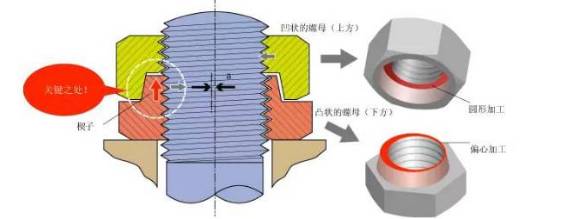

The method he thought of was to use two kinds of nuts in the shape of "concave" and "convex" on a screw. The convex nut below acts as a wedge when the center is slightly staggered during machining (eccentric machining). The concave nut above does not deviate from the center (circular processing), so it forms the function of hammering wedges( Figure 2) when the two nuts are combined into one, the loosening problem is solved.

3. Although there are many imitators, there are few winners

Of course, the success of hardlock nut will also attract many imitators to imitate.

In fact, the principle and structure of hardlock nuts are relatively simple, which is introduced in detail on the website of hardlock industry. Although there are many imitators, there are few winners. This is the key to technology. Although you know the principle and structure of this tenon nut, you just can't produce a nut that won't loosen. This is what people are good at.

From the above introduction, it seems that the invention of this nut is not difficult, but it is very difficult to popularize. In fact, this is an illusion. It is not very difficult to invent a nut with such a structure, but it still needs to be continuously improved in use to really turn the invention into a real nut that will never loosen.

From the establishment of this company to the full use of Japan's largest railway company, Ruolin spent nearly 20 years. The continuous technical improvement in the past 20 years has made the hard lock nut the only nut that will never loosen in the world.

Hadlock company specially noted on the website that the unique technology and know-how accumulated by the company over the years have different corresponding eccentric core quantities for different sizes and materials, which is the key to the impossibility of hard lock nuts.

Well, even if people clearly tell you the principle and structure of this nut, the actual production still needs special experience. This is technology and this is know-how.

Without this technology, even if you understand the principle of this nut, you can't produce it. The awesome thing about many enterprises is that they have this unique technology that you can't learn.

4. Transactions from aircraft manufacturers

So far, "hard lock nut" has been adopted by railways in Australia, Britain, Poland, China and South Korea, and Shinkansen (Taiwan High Speed Railway) in Taiwan has also adopted this product.

In addition to railways, many countries and regions at home and abroad, such as the world's longest suspension bridge, Japan's "Akashi Strait Bridge", the world's highest self-supporting radio tower "Tokyo Sky Tree", the U.S. space shuttle launch pad and ocean drilling machine, have adopted the "hard lock nut".

Inventor Ruolin is still buried in technological innovation today when "hard lock nut" is famous in the world, and has successively developed new products such as "single nut" to improve operation efficiency and "special bearing nut" to prevent bearing loosening. In addition, they are still negotiating with Boeing of the United States and Rolls Royce of Europe, the world's largest aircraft manufacturer, to develop lightweight products for aircraft.

Ruolin is one of the few collectors of railway models. He said that when playing with railway models, inspiration will also flash in his mind. He opened a collection exhibition area on the second floor of the factory. The visitors were all excited after the visit. Ruolin said that whether in work or hobbies, "it can make everyone happy, happier than anything."

The concept of "hard lock nut" is very simple, that is, a wedge is inserted between the nut and the screw to prevent loosening( Fig. 1) however, it is neither efficient nor realistic to insert wedges one by one into the nuts to be used at the construction site. How can the wedge function? Ruolin thought hard.

The method he thought of was to use two kinds of nuts in the shape of "concave" and "convex" on a screw. The convex nut below acts as a wedge when the center is slightly staggered during machining (eccentric machining). The concave nut above does not deviate from the center (circular processing), so it forms the function of hammering wedges( Figure 2) when the two nuts are combined into one, the loosening problem is solved.

3. Although there are many imitators, there are few winners

Of course, the success of hardlock nut will also attract many imitators to imitate.

In fact, the principle and structure of hardlock nuts are relatively simple, which is introduced in detail on the website of hardlock industry. Although there are many imitators, there are few winners. This is the key to technology. Although you know the principle and structure of this tenon nut, you just can't produce a nut that won't loosen. This is what people are good at.

From the above introduction, it seems that the invention of this nut is not difficult, but it is very difficult to popularize. In fact, this is an illusion. It is not very difficult to invent a nut with such a structure, but it still needs to be continuously improved in use to really turn the invention into a real nut that will never loosen.

From the establishment of this company to the full use of Japan's largest railway company, Ruolin spent nearly 20 years. The continuous technical improvement in the past 20 years has made the hard lock nut the only nut that will never loosen in the world.

Hadlock company specially noted on the website that the unique technology and know-how accumulated by the company over the years have different corresponding eccentric core quantities for different sizes and materials, which is the key to the impossibility of hard lock nuts.

Well, even if people clearly tell you the principle and structure of this nut, the actual production still needs special experience. This is technology and this is know-how.

Without this technology, even if you understand the principle of this nut, you can't produce it. The awesome thing about many enterprises is that they have this unique technology that you can't learn.

4. Transactions from aircraft manufacturers

So far, "hard lock nut" has been adopted by railways in Australia, Britain, Poland, China and South Korea, and Shinkansen (Taiwan High Speed Railway) in Taiwan has also adopted this product.

In addition to railways, many countries and regions at home and abroad, such as the world's longest suspension bridge, Japan's "Akashi Strait Bridge", the world's highest self-supporting radio tower "Tokyo Sky Tree", the U.S. space shuttle launch pad and ocean drilling machine, have adopted the "hard lock nut".

Inventor Ruolin is still buried in technological innovation today when "hard lock nut" is famous in the world, and has successively developed new products such as "single nut" to improve operation efficiency and "special bearing nut" to prevent bearing loosening. In addition, they are still negotiating with Boeing of the United States and Rolls Royce of Europe, the world's largest aircraft manufacturer, to develop lightweight products for aircraft.

Ruolin is one of the few collectors of railway models. He said that when playing with railway models, inspiration will also flash in his mind. He opened a collection exhibition area on the second floor of the factory. The visitors were all excited after the visit. Ruolin said that whether in work or hobbies, "it can make everyone happy, happier than anything."

Previous:Why do wind turbine blades not fall during transportation? You'll know after reading this

Next:Basic knowledge of rolling bearing

Related Information

- Industry news

- The tap or drill bit breaks in the hole, how to fix it?

- Why do airplanes use rivets instead of welding?

- Why are engineering drawings all blueprints?

- How is a ping pong ball made? It turns out that it is made of two pieces of plas

- What to do if quality is abnormal? Doing these 3 things well is the key!

- Weekly News 9.7-9.13

- Huawei's three-fold screen is approaching, and the domestic supply chain is wait

- Innovative application of digital twin technology in integrated die-casting prod

- 5 types of carbide cutting tools, what are the differences? Save this article an

- Global manufacturing PMI in June was 49.5% | Weekly News 7.6-7.12

- Raw material defects | Machining special operations and practical cases 109

- No wonder Toyota stamping is so good: a day in the life of a Toyota stamping sho

- Analysis on the development trend and demand of China's mold industry

- How many types of sealing rings are there in machinery? What are they used for?

- Hangfa, Hangfa, a scar on the hearts of machine processing workers

- How to mill a large arc surface with a small cutter?

- Dynamics of the processing center of the process! What is the fundamental reason

- 500 ° C ultra -strong aluminum alloy! This problem is overcome

- How much do you know about the hometown of machine tools and molds, how much do

BACK

BACK MT HOME

MT HOME Navbar

Navbar