Can I do CNC programming if I have never done a CNC operation of a machining center and have no experience in using the machine?

2021.04.20

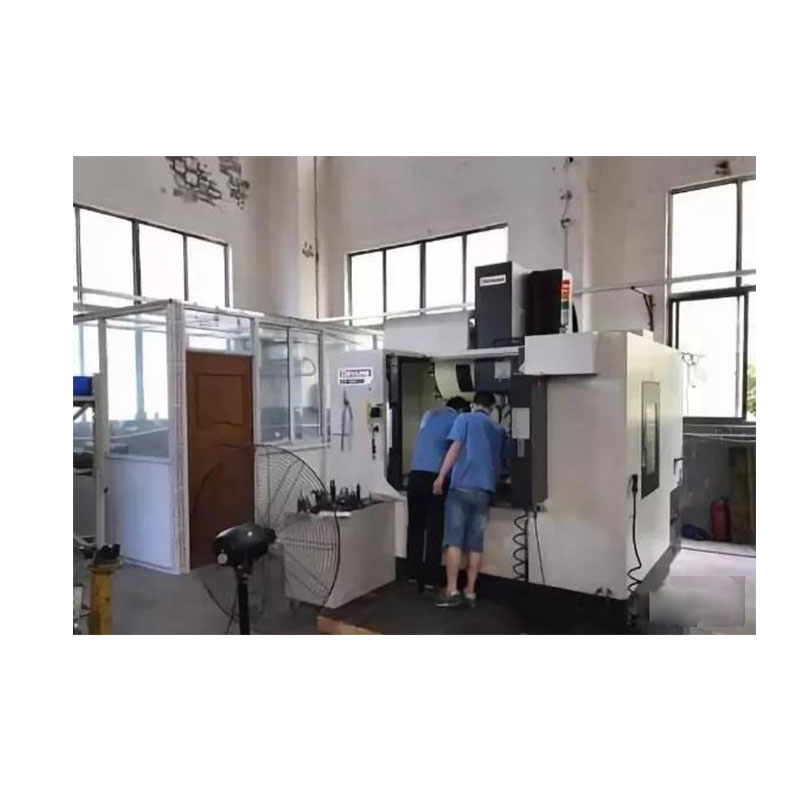

Without operating experience, all kinds of problems will definitely arise in the compiled program, and practical operation is the only criterion for testing truth. Only a master who has been accumulated for a long time can compile a soulful program. Many factors must be considered in programming: cutting tools, fixtures, product technology, and machine tool performance are all involved. It is not just a program that can be solved with a regular knife.

If you want to learn programming, you have to start with the operation first, and there is no rush. I used to work in a machinery factory, and the factory bought more than 800,000 imported CNCs for finishing. A college graduate came for an interview. He brags that he has experience. Within two days, he broke the boss’s 3,000 knives, and the glass on the machine’s door was rotten. As soon as he saw that there was no problem with his program, he just installed the knife and replaced it. The knife didn't consider it well. It seems simple to make machinery, but in fact a small detail will make you regret it.

Each of us has had an internship experience. During the internship process, you will find that the work you are currently engaged in may be just a certain course you learned in school, and a lot of knowledge is not used. But it is precisely how proficient you can master this course. Take the general car as an example. You can practice for up to two months during the school period, but you can really learn the general car technology. I think two years may be counted. Fast.

Besides, what have they been studying during the extra two years? It's definitely not the same as training basic skills at school! Talking about CNC programming again, it can be said that all experience is included in the program. Without practical experience, your program may not be used by others! It takes 45 seconds for your program to process a workpiece, and 43 seconds for a program compiled by others. The difference between a workpiece is 2 seconds, and all employees of an enterprise may not be 2 seconds!

In addition, as far as I know, all those who study CNC majors, whether they are junior colleges or undergraduates, or even graduate students, must go to the front line of the company to work for about half a year after entering the company, and then transfer to the office to engage in craftsmanship and design. Only after you fully understand the production conditions of your company, can you compile the correct CNC machining process and the reasonable CNC program! But nothing is absolute. I have seen people who can't program at all operate CNC machine tools. Some people go directly to the technical department after graduation! How to say?

Previous:The Germans' understanding of quality is streamlined and just the point!

Next:How to judge the accuracy of a machining center?

Related Information

- Industry news

- The tap or drill bit breaks in the hole, how to fix it?

- Why do airplanes use rivets instead of welding?

- Why are engineering drawings all blueprints?

- How is a ping pong ball made? It turns out that it is made of two pieces of plas

- What to do if quality is abnormal? Doing these 3 things well is the key!

- Weekly News 9.7-9.13

- Huawei's three-fold screen is approaching, and the domestic supply chain is wait

- Innovative application of digital twin technology in integrated die-casting prod

- 5 types of carbide cutting tools, what are the differences? Save this article an

- Global manufacturing PMI in June was 49.5% | Weekly News 7.6-7.12

- Raw material defects | Machining special operations and practical cases 109

- No wonder Toyota stamping is so good: a day in the life of a Toyota stamping sho

- Analysis on the development trend and demand of China's mold industry

- How many types of sealing rings are there in machinery? What are they used for?

- Hangfa, Hangfa, a scar on the hearts of machine processing workers

- How to mill a large arc surface with a small cutter?

- Dynamics of the processing center of the process! What is the fundamental reason

- 500 ° C ultra -strong aluminum alloy! This problem is overcome

- How much do you know about the hometown of machine tools and molds, how much do

BACK

BACK MT HOME

MT HOME Navbar

Navbar