If the small mold exhaust is not done well, the product can be messed up

2021.02.18

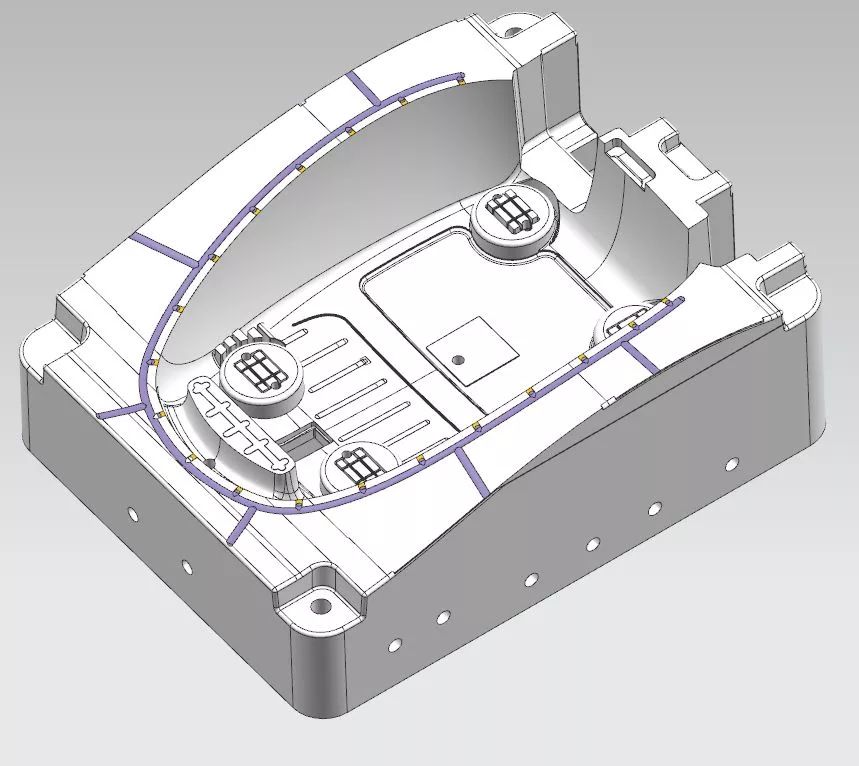

In a sense, the injection mold is also a displacement device, that is, the plastic melt enters the mold cavity and simultaneously replaces the air in the mold cavity. In fact, the air in the mold is not limited to the cavity, especially the three-plate injection mold. The air in the runner cannot be ignored. In addition, the plastic melt will generate a small amount of decomposition gas. These gases must be discharged in time.

If the mold's exhaust performance is poor, it is easy to produce bubbles, silver streaks, clouds, filling dissatisfaction, surface burn marks, intermittent injection and other defects. Therefore, the mold must be equipped with a reasonable exhaust structure to avoid product defects caused by poor exhaust.

1. Several common exhaust methods

1) Exhaust from the exhaust slot

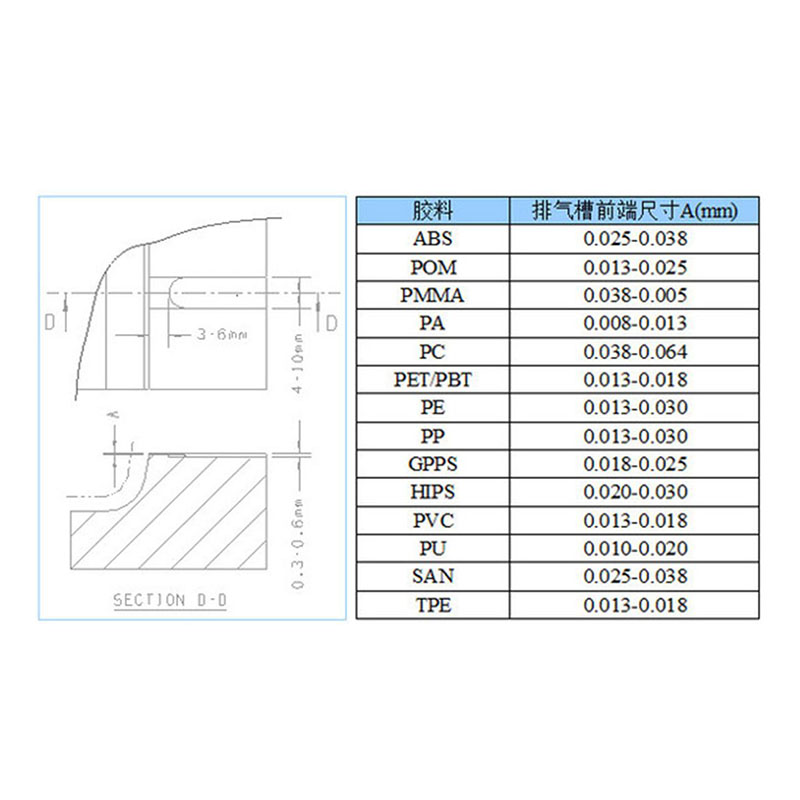

For molds for forming large and medium-sized plastic parts, the amount of gas that needs to be removed is large, and the exhaust groove is usually opened on the side of the concave mold on the parting surface. The location of the exhaust slot is better at the end of the melt flow, and the size of the exhaust slot is based on the principle that the gas can be smoothly discharged without overflow. The width of the exhaust groove is generally about 3-5mm, the depth of the front end of the exhaust groove is less than 0.05mm, and the length is generally 0.7-1.0mm. The depth of the commonly used exhaust groove can be verified in the <Plastic Mold Technical Manual>.

2) Parting surface exhaust

For small molds, the parting surface gap can be used to vent, but the parting surface must be at the end of the melt flow.

3) Exhaust the gap of the mosaic

For combined die or cavity, the split gap can be used to vent.

4) Exhaust the push rod gap

Use the matching clearance between the push rod and the template or core to exhaust, or intentionally increase the clearance between the push rod and the template.

5) Exhaust of powder unsintered alloy block

The powder unsintered alloy is a material sintered with a spherical particle alloy, which has poor strength but is loose in texture and allows gas to pass through. Placing a piece of such alloy in the part that needs to be vented can meet the requirements of venting, but the diameter of the bottom vent hole should not be too large to prevent it from being squeezed and deformed by the pressure of the cavity.

6) Exhaust well

On the outside of the plastic melt confluence, a cavity is provided to allow gas to be discharged into it, and a good exhaust effect can also be obtained.

7) Mandatory exhaust

Set the exhaust rod in the part where the gas is enclosed. This method has a good exhaust effect but will leave traces of the rod on the plastic part, so the exhaust rod should be located in a hidden place of the plastic part.

2. Matters needing attention in exhaust design

1) When the exhaust is extremely difficult, the inlay structure is used. If the dead corners of the mold are not easy to open the exhaust groove, first of all, the mold should be appropriately changed to inlay processing without affecting the appearance and accuracy of the product, which is not only beneficial to processing Exhaust can also improve the original processing difficulty and facilitate maintenance.

2)In the closed shape of the plastic product, a thimble must be added to exhaust gas and prevent burns and melting marks.

3) For product molds with complex geometric shapes, it is best to determine the opening of the exhaust slot after several mold trials.

4) The thinner the product, the farther away from the gate, the opening of the exhaust groove is particularly important.

5)For small parts or precision parts, we should also pay attention to the opening of the exhaust groove, because it can avoid surface burns and insufficient injection volume of the product, and can also eliminate various defects of the product.

3.Summary

Properly opening the exhaust groove can greatly reduce the injection pressure, injection time, holding time and clamping pressure, so that the molding of plastic parts is changed from difficult to easy, thereby improving production efficiency, reducing production costs, and reducing machine energy consumption.

Details determine success or failure, and the details of the mold must be handled carefully!

Previous:How to choose gate location (water inlet) for mold design

Next:Take a look at what is screen printing technology!

Related Information

- Industry news

- The tap or drill bit breaks in the hole, how to fix it?

- Why do airplanes use rivets instead of welding?

- Why are engineering drawings all blueprints?

- How is a ping pong ball made? It turns out that it is made of two pieces of plas

- What to do if quality is abnormal? Doing these 3 things well is the key!

- Weekly News 9.7-9.13

- Huawei's three-fold screen is approaching, and the domestic supply chain is wait

- Innovative application of digital twin technology in integrated die-casting prod

- 5 types of carbide cutting tools, what are the differences? Save this article an

- Global manufacturing PMI in June was 49.5% | Weekly News 7.6-7.12

- Raw material defects | Machining special operations and practical cases 109

- No wonder Toyota stamping is so good: a day in the life of a Toyota stamping sho

- Analysis on the development trend and demand of China's mold industry

- How many types of sealing rings are there in machinery? What are they used for?

- Hangfa, Hangfa, a scar on the hearts of machine processing workers

- How to mill a large arc surface with a small cutter?

- Dynamics of the processing center of the process! What is the fundamental reason

- 500 ° C ultra -strong aluminum alloy! This problem is overcome

- How much do you know about the hometown of machine tools and molds, how much do

BACK

BACK MT HOME

MT HOME Navbar

Navbar