The slider comes out of the slider. Have you ever used this classic mold structure?

2021.01.25

When we design the mold, we always encounter some more complex mechanisms, such as the slider out of the slider, the slider out of the inclined top, the slider out of the top needle, and so on. Today I would like to share three classic structures.

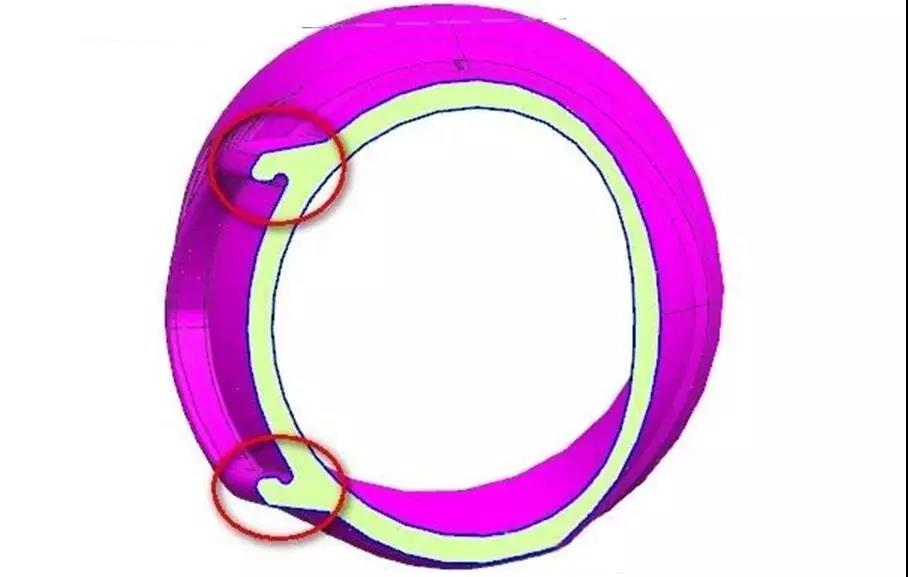

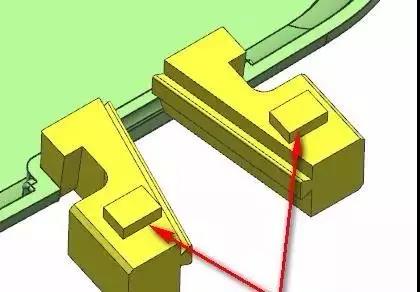

Case 1:

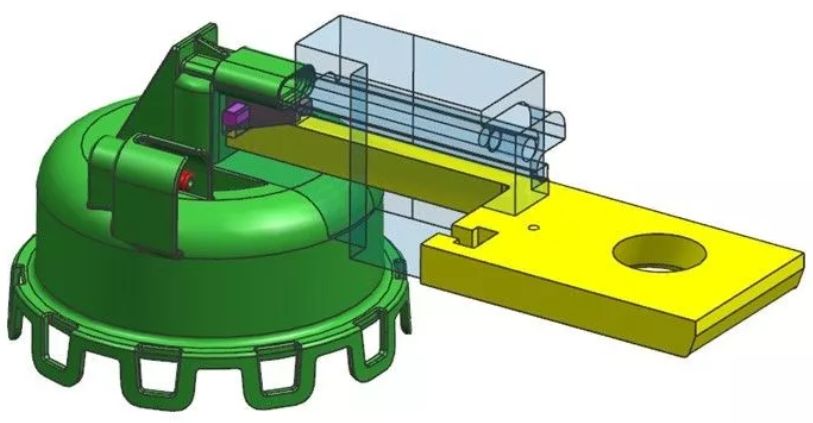

1. Slider design idea: the inside buckle must be separated first, and then side core pulling together, as shown in the figure, the small green slider must be core pulling in the middle first, and separated from the inner buckle.

2. The driving force of the small green slider is a gray driving block, which is designed with dovetail groove and driven by inclined guide post, as shown in the figure

3. Because the small green slider must be pulled out of the buckle first, and the large slider cannot be pulled out of the core first, so the delay mechanism must be made. The inclined guide post through hole of the large slider is designed as an ellipse, as shown in the figure

4. The limit device must be designed for the small green slider to slide along the tripping direction, as shown in the figure:

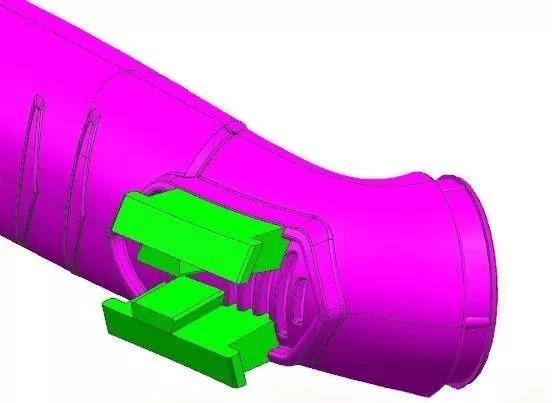

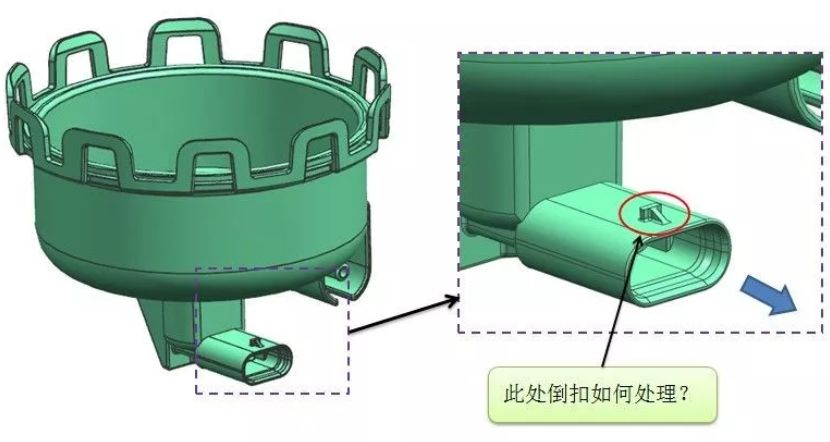

Case 2:

1. There are two side holes in this product. It is impossible to get out of the mold when making ordinary slider, so it is necessary to design the slider inside.

2. Firstly, two small sliders are designed, and the inclined plane is provided with dovetail groove, and the direction of the small sliders is the direction of the red arrow.

3. The pipe position should be made when the small slider slides, and a guide groove should be opened on the back die core, as shown in the figure

4. The insert for driving the small slider is designed to fit with the swallow tail of the small slider, as shown in the figure.

5. The inclined guide pillar drives the slide block to pull the core laterally, and the dovetail groove drives the small slide block to pull the core inward to complete the core pulling of the lateral hole.

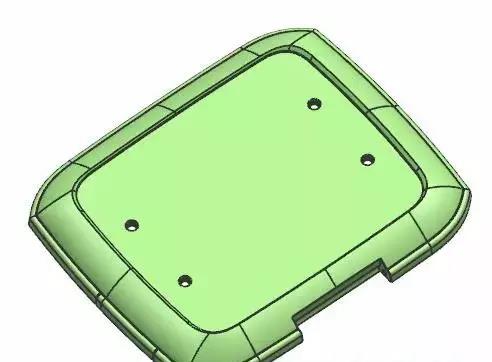

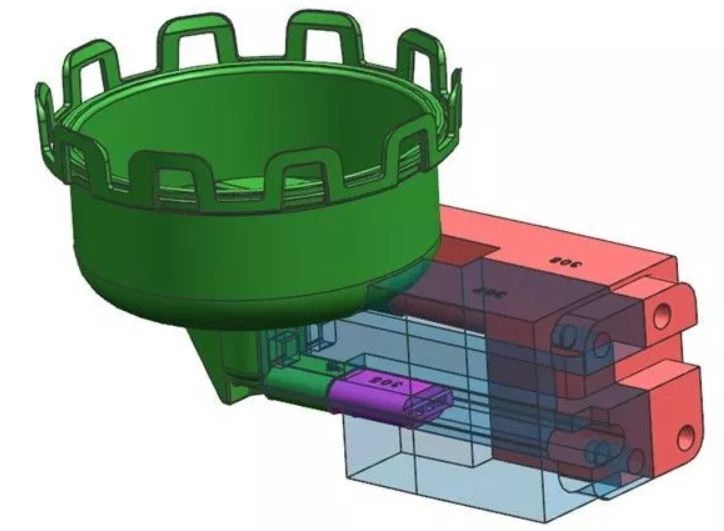

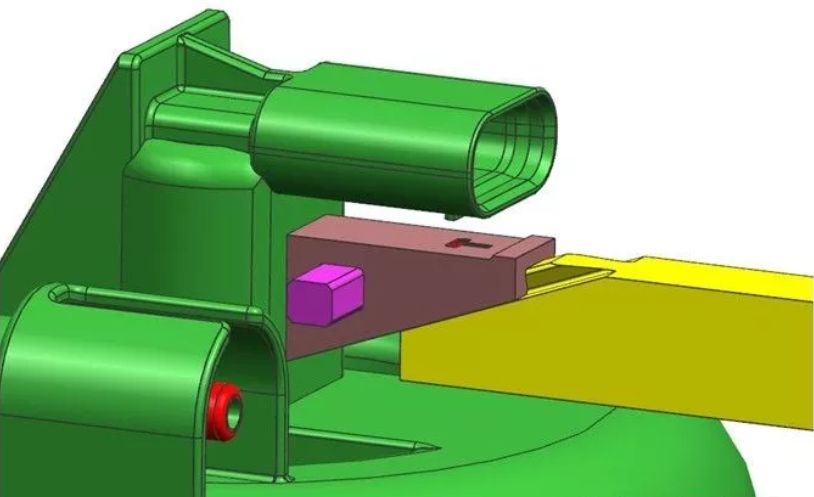

Case 3:

1. Design the slider insert first, and do not need to deal with the bone position inside, as shown in the figure.

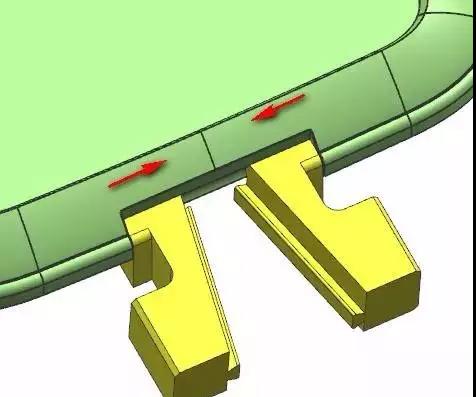

2. Design a small slider. The swallow tail groove is used to drive the small slider. The pink square is the positioning block, and the Yellow driving block is pulled in the direction of the arrow. Due to the function of the swallow tail groove, the small slider slides downward and breaks away from the buckle

3. Use the inclined guide post to drive the slider, the slider needs to do delayed core pulling, first drive the Yellow drive block, drive the small slider to pull the core, and then delay the core pulling in place, continue to pull the core, and take off all the buckles.

Previous:CNC skills: judging the processing condition by looking at the color of scrap iron

Next:The selection skill of gate position (water inlet) in mold design

Related Information

- Industry news

- The tap or drill bit breaks in the hole, how to fix it?

- Why do airplanes use rivets instead of welding?

- Why are engineering drawings all blueprints?

- How is a ping pong ball made? It turns out that it is made of two pieces of plas

- What to do if quality is abnormal? Doing these 3 things well is the key!

- Weekly News 9.7-9.13

- Huawei's three-fold screen is approaching, and the domestic supply chain is wait

- Innovative application of digital twin technology in integrated die-casting prod

- 5 types of carbide cutting tools, what are the differences? Save this article an

- Global manufacturing PMI in June was 49.5% | Weekly News 7.6-7.12

- Raw material defects | Machining special operations and practical cases 109

- No wonder Toyota stamping is so good: a day in the life of a Toyota stamping sho

- Analysis on the development trend and demand of China's mold industry

- How many types of sealing rings are there in machinery? What are they used for?

- Hangfa, Hangfa, a scar on the hearts of machine processing workers

- How to mill a large arc surface with a small cutter?

- Dynamics of the processing center of the process! What is the fundamental reason

- 500 ° C ultra -strong aluminum alloy! This problem is overcome

- How much do you know about the hometown of machine tools and molds, how much do

BACK

BACK MT HOME

MT HOME Navbar

Navbar