Whirlwind milling , the magical tool for thread processing

2020.11.02

What is whirlwind milling?

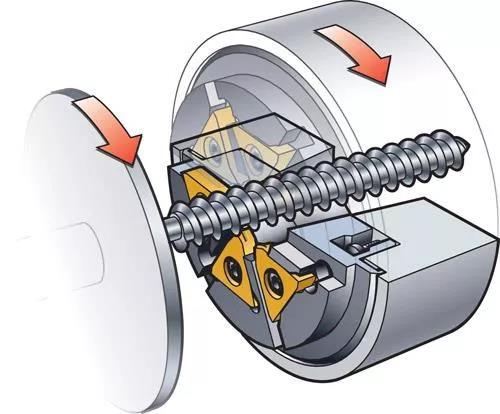

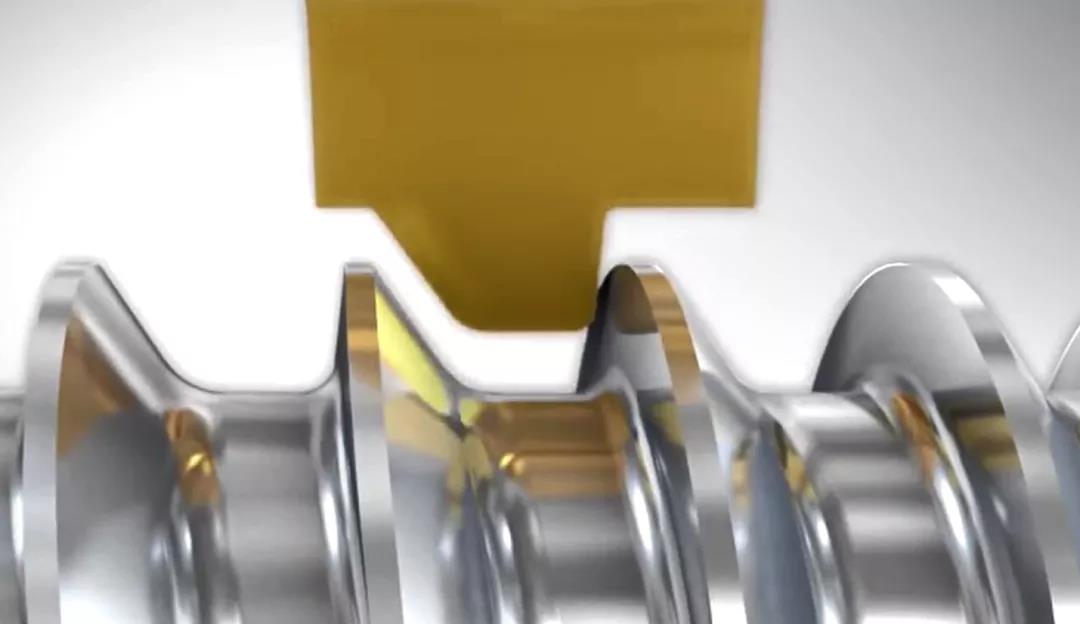

Because of its high milling speed (speed up to 400m/min), the processing efficiency is fast, and compressed air is used for chip cooling. The cutting splash during the machining process is named after the whirlwind.

Whirlwind milling thread is a whirlwind milling head to process the thread, and only one cut can complete the thread processing method.

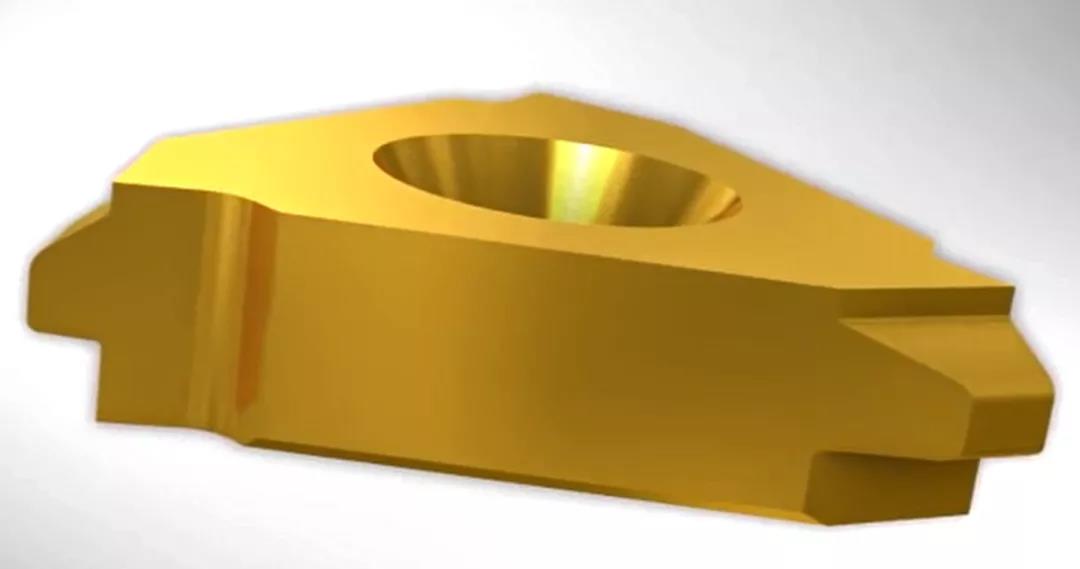

Whirlwind milling tool determination process

01. Determine part shape

02. Determine the tool shape according to the part

03. Make the corresponding blade

Several companies specialize in the production of thread milling blades, such as Camus, NTK, Haoen and domestically made Fengyi. Fengyi cutters are commonly used professional blades for domestic whirlwind milling equipment.

04. Install the blade on the cutter head

Five movements of whirlwind milling

After the cyclone milling machine is matched with the lathe, five processing motions need to be completed during the processing process:

The cutter head drives the cemented carbide forming knife to rotate at high speed (main movement)

The lathe spindle drives the workpiece to rotate slowly (auxiliary movement)

Cyclone milling moves along the workpiece axis (feed motion) according to the workpiece pitch or lead

Cyclone milling carries out radial movement (cutting movement) driven by the carriage in the lathe

Whirlwind milling has the freedom to adjust the helix angle within a certain angle range (rotational movement)

Advantages of whirlwind milling

The advantages of whirling thread cutting:

1. High processing efficiency, higher than traditional turning processing efficiency! The highest can reach more than 10 times.

2. The product is formed in one cut, no need to retract for eccentric cutting.

3. Without changing the structure of the lathe, the spiral lift angle is adjustable, and the installation is convenient.

4. The surface roughness can reach Ra0.8 microns or even higher, and the processing accuracy can be improved by 2 levels.

5. The programming method is simple and fast, and the positioning accuracy of the forming blade, the blade and the blade slot is high, which reduces the technical requirements of the workers.

Cyclone milling can achieve dry cutting, heavy-duty cutting, difficult-to-machine materials and ultra-high-speed cutting, with low power consumption. The surface roughness can reach Ra0.8μm. The spindle speed of the lathe is slow, so the machine has high motion accuracy and good dynamic stability. It is an advanced thread processing method.

Previous:Don't forget the process industry to build a smart factory

Next:5 common misunderstandings in mechanical equipment lubrication

Related Information

- Industry news

- The tap or drill bit breaks in the hole, how to fix it?

- Why do airplanes use rivets instead of welding?

- Why are engineering drawings all blueprints?

- How is a ping pong ball made? It turns out that it is made of two pieces of plas

- What to do if quality is abnormal? Doing these 3 things well is the key!

- Weekly News 9.7-9.13

- Huawei's three-fold screen is approaching, and the domestic supply chain is wait

- Innovative application of digital twin technology in integrated die-casting prod

- 5 types of carbide cutting tools, what are the differences? Save this article an

- Global manufacturing PMI in June was 49.5% | Weekly News 7.6-7.12

- Raw material defects | Machining special operations and practical cases 109

- No wonder Toyota stamping is so good: a day in the life of a Toyota stamping sho

- Analysis on the development trend and demand of China's mold industry

- How many types of sealing rings are there in machinery? What are they used for?

- Hangfa, Hangfa, a scar on the hearts of machine processing workers

- How to mill a large arc surface with a small cutter?

- Dynamics of the processing center of the process! What is the fundamental reason

- 500 ° C ultra -strong aluminum alloy! This problem is overcome

- How much do you know about the hometown of machine tools and molds, how much do

BACK

BACK MT HOME

MT HOME Navbar

Navbar