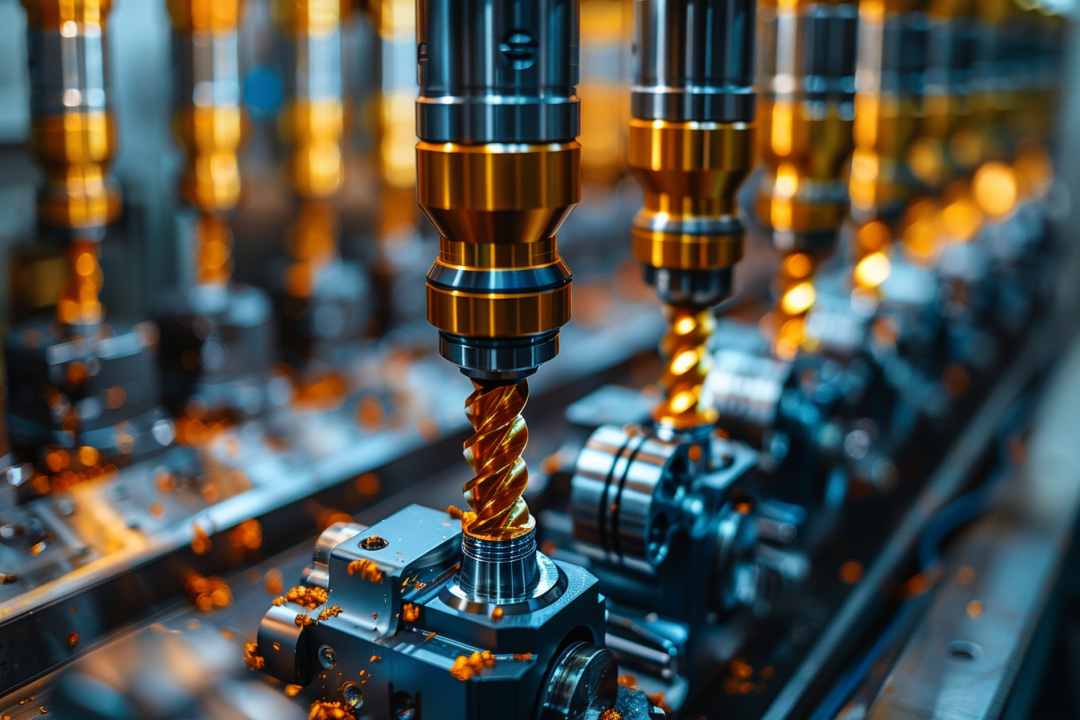

Keyword: CNC machining parts Auto Spare Parts Milling machining Turning parts Grinding machining

Contact person: Nick Lee

Phone: (86) 15362887736

E-mail: sales03@dgmtwj.cn

Tel: (86) 769-88388276

Factory: No.2, Baidai Industrial Park, Daojiao Town, Dongguan, China ,

Carbide tools have excellent performance and their current status needs no further explanation. However, there are many types of carbide tools, and some readers only know the characteristics of one or two of them, or rarely think about the differences between them. Therefore, we have collected information on 14 types of carbide tools, hoping to be helpful to everyone.

1 Tungsten-cobalt carbide (tungsten steel)

Tools made of WC-Co tungsten-cobalt carbide are suitable for processing ordinary steel and stainless steel, cast iron, non-ferrous metals (such as copper, aluminum, brass), alloy steel and tool steel, high-hardness materials (such as hardened steel) and other hard and high-strength materials.

1. Material characteristics

① High hardness: extremely high hardness, so that it can maintain a sharp blade during cutting.

② High toughness: good toughness, can withstand large cutting forces and impacts.

③ Wear resistance: very good wear resistance, can extend the service life of the tool.

④ Thermal stability: can maintain mechanical properties during high-temperature cutting, reduce tool wear and deformation.

2. Processing advantages

① High precision: tungsten-cobalt carbide tools can achieve high-precision processing and are suitable for the manufacture of precision parts.

② Fast speed: suitable for high-speed cutting, improve processing efficiency and shorten processing time.

③ Wide applicability: can adapt to a variety of processing conditions and environments, with a wide range of applications.

3. Typical applications

①Automobile manufacturing: used to produce engine parts and gearbox gears.

②Aerospace: manufacturing aircraft fuselages and engine parts.

③Mold manufacturing: used to manufacture high-precision injection molds and stamping molds.

④Machining: used to process various precision mechanical parts.

In short, compared with other cemented carbides, tungsten-cobalt cemented carbides have extremely high toughness, are particularly suitable for withstanding large cutting forces and impacts, and are more suitable for heavy-duty processing tasks that require high strength and durability.

02 Titanium, tungsten and cobalt cemented carbide

Tools made of TiC-WC-Co titanium tungsten cobalt cemented carbide are suitable for processing high-strength steel, titanium alloy, nickel-based alloy, stainless steel and other difficult-to-process materials.

1. Material characteristics

① High hardness: It has extremely high hardness, which enables it to maintain a sharp blade during cutting.

② High strength: Good strength, able to withstand large cutting forces and impacts.

③ Wear resistance: Very good wear resistance, which can extend the service life of the tool.

④ Anti-oxidation: It can maintain mechanical properties during high-temperature cutting and reduce tool wear and deformation.

2. Processing advantages

① High precision: Titanium tungsten cobalt cemented carbide tools can achieve high-precision processing and are suitable for the manufacture of precision parts.

② Fast speed: Suitable for high-speed cutting, improve processing efficiency and shorten processing time.

③ Good heat resistance: Able to adapt to high-temperature processing conditions and maintain stable performance.

3. Typical applications

① Automobile manufacturing: used to produce high-strength parts and engine components.

② Aerospace: Manufacturing aircraft fuselages, engines and other key components.

③ Medical equipment: used to manufacture high-precision medical tools and equipment.

④ Energy industry: used to process key parts in oil, gas and power equipment.

In short, compared with other cemented carbides, titanium-tungsten-cobalt cemented carbides have better oxidation resistance and heat resistance, and are particularly suitable for processing tasks with high strength and durability requirements in high temperature environments.

03 Tantalum, tungsten and cobalt cemented carbide

Tools made of TaC-WC-Co tantalum tungsten cobalt carbide are suitable for processing wear-resistant steel, high-temperature alloys, difficult-to-cut materials, etc.

1.Material characteristics

①High hardness: It has extremely high hardness to ensure that the blade is sharp during the cutting process.

②High toughness: Good toughness, able to withstand large cutting forces and impacts.

③Wear resistance: Excellent wear resistance, significantly extending the service life of the tool.

④ Thermal stability: It can maintain mechanical properties in high temperature environments and reduce tool wear and deformation.

2. Processing advantages

① High precision: It can achieve high-precision processing and is suitable for the manufacturing of high-precision parts.

② Good heat resistance: capable of cutting under high temperature conditions to improve processing efficiency.

③ Corrosion resistance: It can maintain stable performance in corrosive environments and has a wide range of applications.

3.Typical applications

①Aerospace: used to manufacture high-temperature components and turbine blades.

②Electronics industry: production of wear-resistant electronic components.

③Medical equipment: manufacturing high-strength surgical tools.

④Energy industry: used to manufacture key parts of nuclear power plant equipment.

In short, compared with other cemented carbide, tantalum, tungsten and cobalt cemented carbide has higher corrosion resistance and toughness, and is particularly suitable for precision machining tasks in corrosive environments and high stress conditions.

4. Titanium Tantalum Tungsten Cobalt Cemented Carbide

Tools made of TiC-TaC-WC-Co titanium tantalum tungsten cobalt cemented carbide are suitable for processing high-strength alloys, heat-resistant alloys and difficult-to-process materials.

1. Material characteristics

① High hardness: It has extremely high hardness to ensure that the tool remains sharp during the cutting process.

② High strength: Excellent strength, able to withstand large cutting forces and impacts.

③ Wear resistance: Excellent wear resistance, extending the service life of the tool.

④ Heat resistance: Maintain good mechanical properties in high-temperature cutting, reduce tool wear and deformation.

2. Processing advantages

① High precision: Suitable for high-precision processing, meeting the requirements of precision parts manufacturing.

② Good heat resistance: Able to process in high-temperature environments to improve processing efficiency.

③ Widely applicable: Suitable for the processing of a variety of materials, with a wide range of applications.

3. Typical applications

① Automobile manufacturing: used for the production of high-precision engine parts.

② Mold manufacturing: Produce high-wear-resistant and high-precision molds.

③ Medical equipment: Suitable for the manufacture of complex surgical implants.

④ Petroleum industry: Key parts for drilling equipment.

In short, compared with other cemented carbides, titanium, tantalum, tungsten and cobalt cemented carbides have higher comprehensive performance and are particularly suitable for complex and precision machining under high strength and high temperature conditions.

5. Aluminum oxide-based cemented carbide

Tools made of Al2O3 aluminum oxide-based cemented carbide are suitable for processing heat-resistant alloys, high-hardness materials and non-metallic materials.

1. Material characteristics

① High hardness: With extremely high hardness, the tool remains sharp during cutting.

② Wear resistance: Excellent wear resistance, extending the service life of the tool.

③ High temperature resistance: Maintain mechanical properties during high-temperature cutting, reduce tool wear and deformation.

④ Chemical stability: Good tolerance to chemical substances such as acids and alkalis.

2. Processing advantages

① High precision: Able to achieve high-precision processing, suitable for the manufacture of precision parts.

② High temperature resistance: Suitable for high-temperature cutting, improve processing efficiency.

③ Corrosion resistance: Can maintain stable performance in corrosive environments.

3. Typical applications

① Aerospace: Used to manufacture high-temperature components and combustion chambers.

② Semiconductor manufacturing: Produce high-purity semiconductor wafers.

③ Optical industry: Used for optical lens processing.

④ Chemical equipment: Manufacture corrosion-resistant chemical reactors.

In summary, compared with other cemented carbides, aluminum oxide-based cemented carbide has higher chemical stability and is particularly suitable for precision machining in high temperature and corrosive environments.

For inquiry and quotation of CNC custom service, please contact :

Phone /Wechat/Whatsapp: +86 13612776575

E-mail:sales03@dgmtwj.cn