Keyword: CNC machining parts Auto Spare Parts Milling machining Turning parts Grinding machining

Contact person: Nick Lee

Phone: (86) 15362887736

E-mail: sales03@dgmtwj.cn

Tel: (86) 769-88388276

Factory: No.2, Baidai Industrial Park, Daojiao Town, Dongguan, China ,

This article explores the innovative application of digital twin technology in the integrated die-casting production of new energy vehicles, focusing on analyzing how virtual debugging and virtual machine tool technology provide key support for the production line. With these advanced digital technologies, production efficiency, process flexibility and quality accuracy are significantly improved.

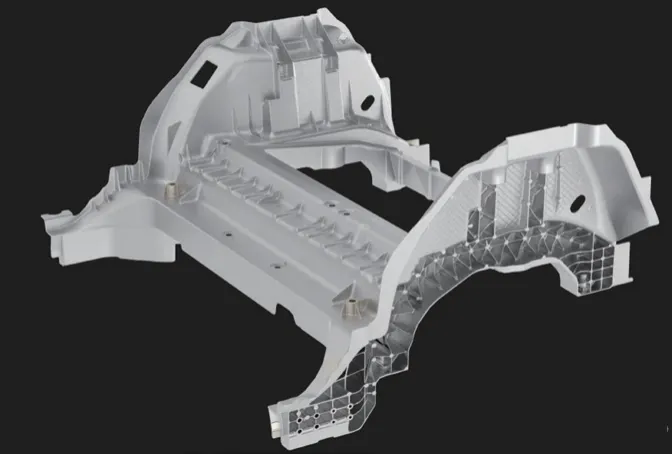

As the world pays more and more attention to sustainable energy and environmental protection, the new energy vehicle industry has ushered in unprecedented development opportunities. In this context, one-piece die-casting technology has become particularly important due to its key role in automobile lightweighting and cost control [1]. Since one-piece die-casting technology is directly related to the performance and market competitiveness of the entire vehicle, its production efficiency and product quality are crucial. One-piece die-casting parts are shown in Figure 1.

Figure 1: One-piece die casting

However, traditional processing equipment faces a series of challenges in the production of one-piece die castings, such as low production efficiency, high cost, and unstable product quality. Fortunately, the rapid development of digital technology has provided a new way to solve these problems. As a cutting-edge concept in modern manufacturing, digital twin technology has been widely used in the one-piece die casting production of new energy vehicles, showing its great potential [2]. It provides an innovative solution for improving production efficiency, reducing production costs, and ensuring product quality by building an accurate digital replica of the physical equipment.

2 Industry Status and New Technologies

With the increase in new energy vehicle brands and models on the market, as well as competition within the industry and the rise of "new forces in car manufacturing", the speed of product iteration is getting faster and faster to adapt to market changes and consumer demand. In order to maintain their competitiveness, companies must speed up product development and iteration, which also brings huge challenges to machine tools supporting new energy. For example, the one-piece die-casting component subframe is a brand-new processing category. In order to meet the requirements of new energy vehicle manufacturers, the supporting machine tool factory needs to redesign and develop production equipment. However, since the machine tool factory faces many difficulties in equipment development, it takes a long time from development to market launch, which cannot meet the changing needs of the market. The introduction of digital twin technology has provided strong support for the technological progress of the new energy vehicle industry. In the development and production process of new energy vehicle processing equipment, the virtual debugging technology of digital twin technology has greatly shortened the equipment development cycle and on-site debugging time. Through the virtual machine tool, the process beat of the parts can be pre-verified before production to ensure a smooth production process [3]. In addition, the machine tool protection function of digital twin technology provides a guarantee for the all-round safety of the machine tool, thereby improving production efficiency and safety.

3 Application of virtual commissioning in equipment development

3.1 Introduction to Virtual Commissioning

The application of virtual commissioning of digital twin technology has brought revolutionary changes to the R&D stage of production equipment. The comparison between virtual commissioning and conventional commissioning is shown in Figure 2. Virtual commissioning abandons the traditional linear R&D process from mechanical design to electrical commissioning and then to automation, and instead adopts a powerful digital design platform to achieve parallel development of mechanical design, electrical commissioning and automation. In this process, repeated trial and error and iterative optimization can be carried out without relying on hardware investment, and all work can be completed in the software environment. After verification and confirmation that the requirements are met, the actual equipment production stage is entered. This method can shorten the actual commissioning time of the equipment by 50%, speed up the product launch, and shorten the overall R&D cycle by about 30%.

3.2 Advantages of Virtual Debugging

Digital twin technology virtual debugging has the following advantages in the production of new energy vehicle parts.

(1) Improve efficiency. Virtual debugging can verify and optimize equipment and process flow before actual equipment manufacturing, reducing actual debugging time and cost.

(2) Reduce risk. By conducting various tests and verifications in a virtual environment, the risk of problems can be reduced, potential problems can be discovered in advance and adjusted.

(3) Improve product quality. Virtual debugging helps to discover and solve problems before production, ensure the accuracy and performance of the subframe, and improve product consistency and reliability.

(4) Optimize design. Virtual debugging can evaluate the design of the subframe, verify its feasibility in actual production, and optimize design parameters.

(5) Reduce physical prototypes. Through virtual debugging, the reliance on physical prototypes can be reduced, R&D costs can be reduced, and the R&D cycle can be shortened.

(6) Training and education. Virtual debugging provides a risk-free environment for operator training and education to improve their familiarity with machine tools and production processes.

(7) Strong adaptability Virtual debugging technology can adapt to different machine tools and production needs, providing flexible solutions for machine tool manufacturers.

(8) Technology integration Virtual debugging technology can be integrated with existing machine tool control systems to achieve more intelligent and automated production processes.

(9) Data-driven decision-making Virtual debugging provides a large amount of data that can be used for analysis, helping machine tool manufacturers make more accurate production decisions based on data.

(10) Environmental friendliness By optimizing the production process, reducing energy consumption and material waste, it meets the requirements of environmental protection and sustainable development.

With the help of virtual debugging technology, machine tool manufacturers can predict the feasibility of producing one-piece die-casting parts in advance and adjust the equipment configuration in time according to changes in part design. This method effectively reduces production costs and risks, while breaking the bottleneck of continuous innovation in the new energy vehicle industry, providing strong support for the vigorous development of the new energy vehicle industry.

For inquiry and quotation of CNC custom service, please contact :

Phone /Wechat/Whatsapp: +86 13612776575

E-mail:sales03@dgmtwj.cn