Keyword: CNC machining parts Auto Spare Parts Milling machining Turning parts Grinding machining

Contact person: Nick Lee

Phone: (86) 15362887736

E-mail: sales03@dgmtwj.cn

Tel: (86) 769-88388276

Factory: No.2, Baidai Industrial Park, Daojiao Town, Dongguan, China ,

Section 1 raw material defect category

1. Case 3: Aluminum Fracture

Material: 7A04-T6 aluminum stick.

Faculture background: During the use of a model of a model, aluminum fracture and falling off during the use of the development phase causes the problem of product failure.

Invasion characteristics:

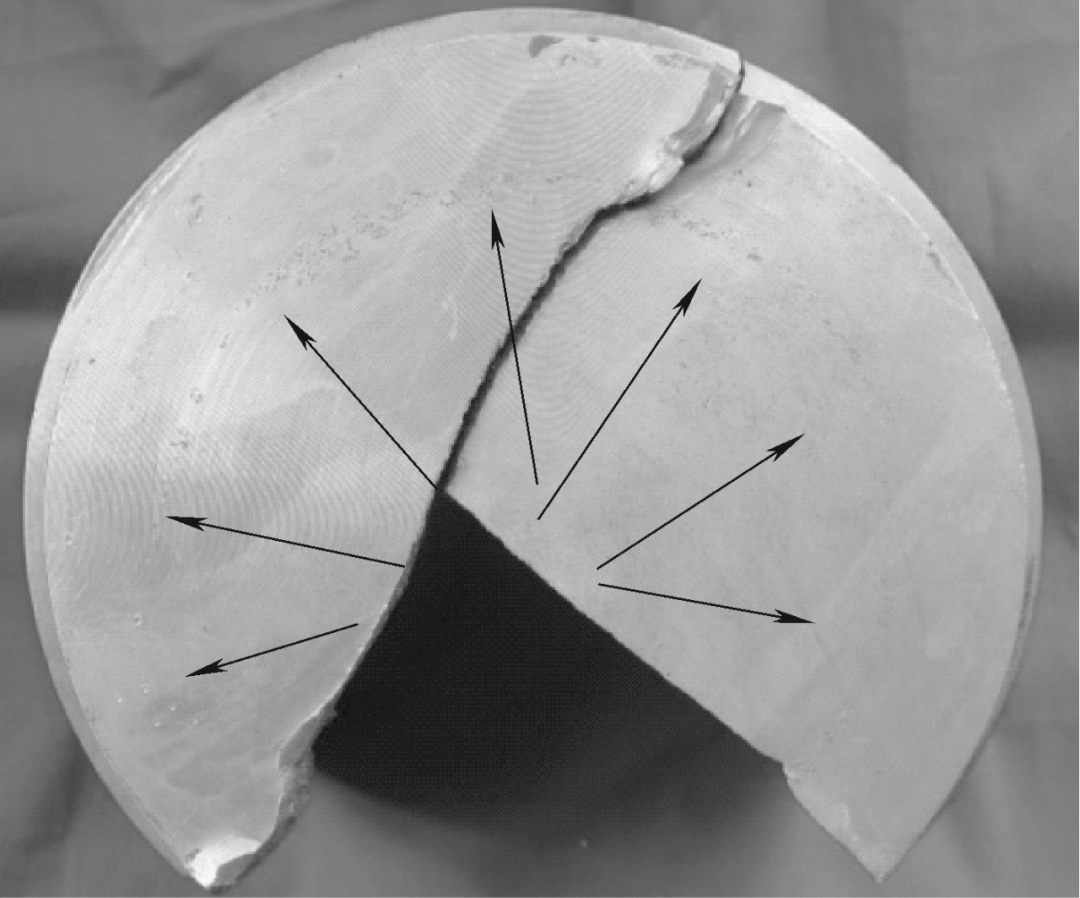

The shape of the fragments of aluminum pieces, as shown in Figure 5-8.

Recycling aluminum remnants form

It is found that there is a ring-shaped and continuous distribution at the bottom surface of the aluminum part, as shown in Figure 5-9.

A total of crack sources were found on the broken surface of the two aluminum pieces. The extension direction is an axis of the aluminum parts, and the length penetrates the entire aluminum part. The linen of a ring-shaped and continuous distribution in Figure 5-9 is actually exposed to defective tissue; And aerobic spinach is mixed, and its color is shown in Figure 5-10, which is darker than the surrounding area.

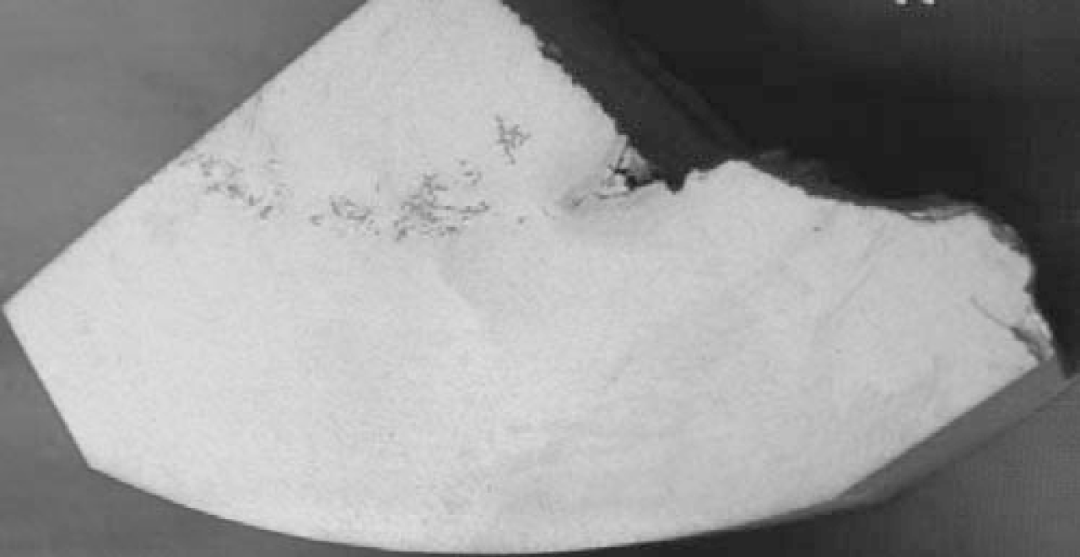

Figure 5-10 The biggest crack source

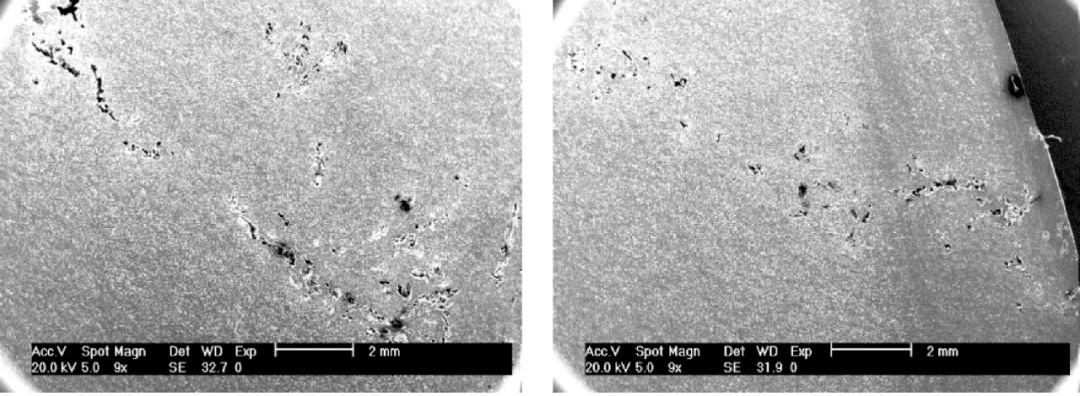

Cut a low-twice sample in the center of the maximum crack source, as shown in Figure 5-11, after corrosion, the arc band flawed belt is shown in Figure 5-12; The situation is shown in Figures 5-13 and Figure 5-14.

Figure 5-11 Sittage of Low-magnalor Simage Sample

Figure 5-12 The surface state after the sample corrodes

Failure mode: Crispy break.

The cause of failure: The raw material (aluminum alloy rod material) itself has serious tail contraction defects that causes aluminum crispy to break.

Correction measures: Add the detection process before the feeding.

Figure 5-13 Lower amplification multiple Mirror image diagram of each part of each part

For inquiry and quotation of CNC custom service, please contact :

Phone /Wechat/Whatsapp: +86 13612776575

E-mail:sales03@dgmtwj.cn