Keyword: CNC machining parts Auto Spare Parts Milling machining Turning parts Grinding machining

Contact person: Nick Lee

Phone: (86) 15362887736

E-mail: sales03@dgmtwj.cn

Tel: (86) 769-88388276

Factory: No.2, Baidai Industrial Park, Daojiao Town, Dongguan, China ,

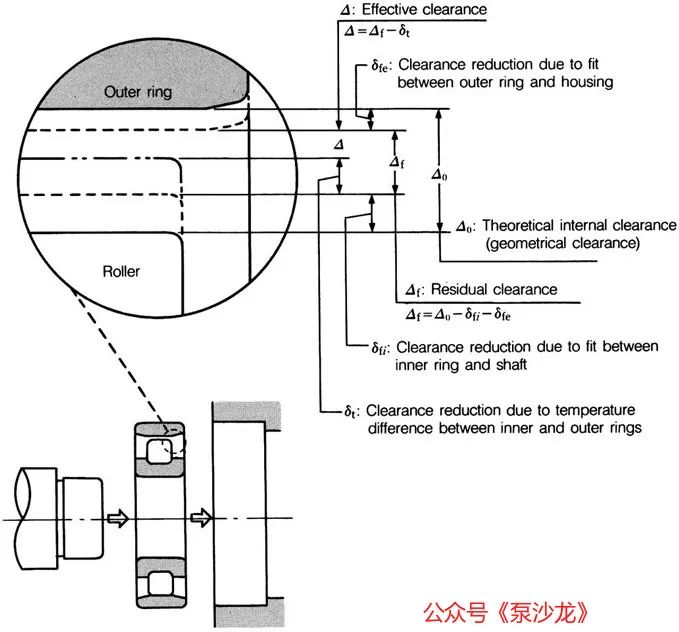

The internal gap of the bearing is a gap that the outer ring and the inner ring in the opposite direction and relative to exercise. Movement along the diameter is a radial gap, while the movement along the axis is axial gap.

Due to a variety of reasons, internal gaps are essential for the use of bearings. The size of the gap will affect the load distribution in the bearing, and the load distribution will eventually affect the service life of the bearing operation noise, vibration and bearing. In addition, the load distribution may also affect the rolling body of the bearings by rolling or sliding motion.

Generally, the inner ring or outer ring of the bearings is installed with a profit. This will lead to expansion (inner ring) or contraction (outer ring), which will cause the internal gap of the bearing after the assembly process to change. When the unit is running, the working temperature of the bearing may usually rise until it reaches the saturated temperature. At this time, the system's heat production and heat discharge reaches a balance.

Although we usually use this general work temperature for the entire bearing, the actual temperature of the inner ring, outer ring and rolling body may be very different.

This temperature difference may cause changes in the internal gap, as shown in Figure 1. In addition, when the bearing runs under the load, the elastic deformation of the inner ring, outer ring and rolling body can also cause changes in the gap. Quantitative all these changes can make the internal gap of the bearing into a complex task. The following is the definition of the gap type.

Internal gap

This is the internal gap measured under the specified load, which can be called "apparent gap". This gap includes elastic deformation caused by load (σfo).

1 = +0 + σfo

Internal gap

This is the internal gap, that is, the measuring gap minus the elastic deformation caused by the load.

-0 = 1 -σfo

σfo is important to the ball bearings, but it is of little significance to the roller bearing, because it is assumed that it is zero, so ∆0 = ∆1.

Residual internal gap ()F)

This is the gap of the bearing installed on the shaft and the shell. Ignoring the elastic deformation caused by the quality of the axis. Assume that the gap caused by the loop (inner and outer ring) is reduced to σf, then:

F = +0+σf

Effective internal gap

This is the bearing gap that the device exists at its working temperature, excluding the flexibility deformation caused by load. This is only a gap caused by the temperature difference σt between σf and the inner ring/outer ring. The basic fixed load of the bearing is only suitable for effective gap ∆ = 0.

– = ∆F -σt = ∆0 - (σf + σt)

Work gap (∆F)

This is the actual gap in installing bearing and running under the load. Here, the effect of elastic deformation fF is included with the cooperation and temperature. Usually, work clearance is not used in calculations.

+F = + σf

The most important bearing gap is a effective gap. Theoretically, effective gaps are the longest life. Under the influence of the bearing load, a slightly negative gap (or pre -load) will become positive. However, it is impossible to make the gaps of all bearings achieve an ideal valid gap. The geometric gap is ∆0 to achieve the minimum valid value of zero or slightly negative. In order to calculate the value, you need to know that the gap caused by the inner and outer circles (cooperation) DF is reduced to reduce the amount of gaps. It is also necessary to know that the temperature difference between the temperature difference between the inner ring and the outer ring DT needs to be changed.

Calculation of the remaining internal gap after installation

When the inner ring pressure of the bearing is coordinated on the bearing, or when the outer circle pressure is matched into the shell, due to the expansion or contraction of the bearing rolling tract, the internal clearance will naturally decrease. Generally speaking, most pumps have a rotating shaft, which requires close cooperation between the inner ring and the axis, and the loose cooperation between the outer ring and the shell. In these cases, you only need to consider the impact on the inner circle.

Formula 1 shows the example calculation of the 6310 single -column deep groove ball bearings. The bearing tolerance used is K5, and the housing is H7 -The inner ring of the bearings adopts a surplus coordination.

Formula 1:

In the formula,

σs = Standard deviation of the axis diameter

σi = standard deviation of the aperture

The standard deviation of σf = interference (contraction or expansion)

σ △ 0 = Standard deviation of the radial gap (before installation)

σ △ F = Standard deviation of the remaining gap (after installation)

MS = axis diameter average (φ50+0.008)

Mi = Pore diameter average (φ50-0.006)

m △ 0 = average of radial gap (before installation, 0.014)

m △ F = Residual Cap Simpage (after installation)

RS = axis diameter tolerance (0.011)

RI = Bearing inner hole tolerance (0.012)

R △ 0 = radial gap range (before installation, 0.017)

λi = The expansion rate caused by apparent interference (reference value 0.75)

The diameter, pore diameter, and radial gap are the standard bearing measurement value. Assuming 99.7 % of the parts within the tolerance range, the average value (M∆F) and standard deviation (σ∆f) of the internal gap (residual gap) after installation can be calculated. The measurement unit is millimeter (mm).

The average amount of expansion and contraction caused by apparent interference is calculated by λi (MM -Mi).

The next formula is used to determine the internal gap change (R∆F) within the probability of 99.7 %:

R∆F = m±f ± 3 ∆F = + 0.014 to-0.007

The average value of the residual gap (M∆f) is + 0.0035, and the internal gap range after installation of 6310 bearing is-0.007 to 0.014.

Radial internal gap and temperature

When the bearing runs under the load, the temperature of the entire bearing will rise, including the rolling body. However, because this change is difficult to measure or estimate, it is usually assumed that the temperature of the rolling element is the same as the inner ring temperature.

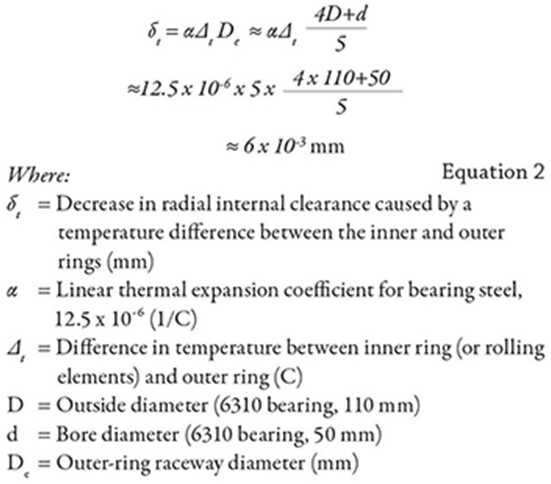

Formula 2:

Taking the 6310 bearing as an example, the formula 2 can be used to calculate the temperature difference between 5 ° C between the inner and the outer ring decreased.

Formula 3:

Ballon bearing: de = (4d + d) / 5

Rolling bearing: de = (3d + d) / 4

Formula 3 is used to calculate the diameter of the outer roller lane. The calculation value of σF and σt can be determined by the internal gap (∆).

Formula 4:

D = df -dt = (+0.014 ~ -0.007) -0.006 = +08 ~ -0.013

Figure 2 shows how an effective internal gap affects the bearings of the bearings. In this example, the radial load is 3,350 n (or 5%of the basic fixed load). When the effective internal gap is -13 μm, the bearings have the longest life. The lower limit of the preferably effective internal clearance range is also -13 μm.

Application

Although theoretically, aimed at a slightly negative gap is the best choice for bearings life, in practice, design or manufacturing bearing must be careful when the pump in the pre -load state must be carefully.

As shown in Figure 2, the life ratio really reaches its peak at -13 μm, but as the pre-load increases, the life span decreases sharply. If the bearing is too large and the processing tolerance or the work temperature is incorrect, it can easily lead to shorter life than expected. On the other hand, excessive gaps will cause bearing noise, rolling element to slip and pump performance worse. Weighing the gap and bearing loading according to the needs of the application.

Understanding the importance of internal gaps in the bearing will help increase the life of the bearings and optimize the overall performance of the pump.