Keyword: CNC machining parts Auto Spare Parts Milling machining Turning parts Grinding machining

Contact person: Nick Lee

Phone: (86) 15362887736

E-mail: sales03@dgmtwj.cn

Tel: (86) 769-88388276

Factory: No.2, Baidai Industrial Park, Daojiao Town, Dongguan, China ,

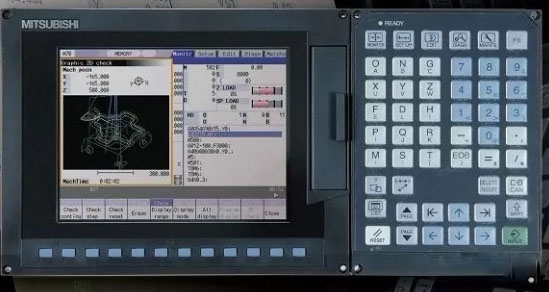

After the hardware connection check and setting of Mitsubishi CNC are completed and power is sent to the system, the ready green light on the display is still not on. In addition, a lot of alarm contents are displayed on the [diagnosis] and [alarm] screen, which puzzles the debugging engineers who use Mitsubishi CNC for the first time.

What's more, Mitsubishi CNC has more than 700 kinds of parameters. Which ones must be set when starting up? How to remove the fault alarm?

According to the debugging experience, this paper explains the above problems in order to help the debugging engineers.

1. Startup parameters

1.1 setting of basic parameters

After the original system is turned on, Japanese is displayed. For the convenience of operation, first set the parameter # 1043 = 22 (Simplified Chinese). (for some systems, if C64 has no simplified Chinese specification, set # 1043 = 15 traditional Chinese).

Set # 1138 = 1 (select parameters with parameter number), that is, after inputting the parameter number, the screen immediately switches to the parameter screen.

The following parameters must be set after power on:

#1001 -- set single system or double system and PLC axis.

#1002 -- set the number of NC axis and PLC axis.

#1013 -- set the name of each axis.

#1037 -- G code system and compensation type

(milling machine: # 1037 = 2, lathe: # 1037 = 3)

(this parameter must be set before performing # 1060 format)

#1060 -- this parameter is particularly important. Its function is "initialization of execution system startup"

There are two functions: one is to initialize the parameters according to the set value of # 1001 - # 1043. The meaning is that the number of NC axes and spindles has been set in # 1001 - # 1043. After # 1060 is set, the parameters of each servo axis and spindle are automatically displayed on the screen. Otherwise, the parameters of each servo axis and spindle will not be called out.

The second is to format the machining program and tool compensation data. Private wechat ug2089 and input standard fixed cycle.

After accurately setting the parameter # 1001 - # 1043, you must set # 1060 according to the prompt. #1155=100 #1156=100

The fixed signal address specified by Mitsubishi NC system is as follows:

1 axis origin x18 1 axis + limit x28 1 axis - limit X20

2-axis origin X19 2-axis + limit X29 2-axis-limit X21

3 axis origin x1a 3 axis + limit x2a 3 axis - limit X22

4-axis origin x1b 4-axis + limit x2b 4-axis-limit x23

If the input signal address occupied by the origin switch and limit switch is different from that specified by the system, it must be changed by setting parameters

#2073 -- set the origin signal address

#2074 -- set positive limit signal address

#2075 -- set negative limit signal address

#Bit5 = 1 for 1226 (make the above settings valid)

1.2 servo motor parameter setting:

#2219 - (position encoder resolution)

#2220 = -- (speed encoder resolution)

#2225 = -- -- (motor model)

#2236 - (connected regenerative braking resistor or power supply unit model)

1.3 parameters related to spindle

When the system is equipped with spindle, the following parameters must be set:

#1039 (the setting system has several spindles);

#3024 - (sets the type of spindle connected

#3024 = 1. Bus connection (i.e. servo spindle)

#3024 = 2 analog output (variable frequency spindle)

#3237 = 0004 (PLG valid)

#3238 = 0004 × 3025 = 2 (encoder feedback series communication is effective. Display the actual speed of the spindle)

#3239 -- spindle servo driver type

#3240 - spindle motor type

#3241 -- type of brake unit or brake resistor connected

1.4 PLC parameters

#6449 = 00000011 -- the counter in PLC program, the timer takes effect.

#6450 = 00000101 -- alarm information and operation information are effective.

#6451 = 00110000 -- PLC program communication is effective.

Mitsubishi NC has as many as 700 parameters, so it is not necessary or possible to set all of them when the machine is started, and the above parameters must be set after the machine is started.

2. Common fault alarm and troubleshooting after power on

After power on, many fault alarms may be displayed on the [diagnosis] - [alarm] screen, and some alarm debugging is not the same as the actual phenomenon, which needs to be solved by analysis and judgment.

2.1 [M01 0006 XYZ] - this fault alarm indicates that one axis or three axes all exceed the hard limit.

Phenomenon: the actual situation is that each axis has not yet moved and has not touched the limit switch.

Troubleshooting:

A. The signal address of each limit switch is connected according to the system regulations, but it is connected to the normally open point, so the system detects the over travel fault.

Disposal: just connect the limit switch to the normally closed point to eliminate the fault.

B. The signal address of each limit switch is not connected according to the system regulations.

Disposal: set the parameters # 2073, # 2074, # 2075, # 1226, and connect the limit switch signal to the normally closed point.

2.2

[S02 2219 XYZ] ,

[S02 2220 XYZ] ,

[S02 2225 XYZ],

[S02 2236 XYZ] - initial parameter setting error.

Disposal: This indicates that the servo parameters set after starting up are not correct, which should be set according to the motor or encoder model.

2.3 [Y03 MCP XYZ] - servo driver not installed

Phenomenon: the actual situation is that the servo driver has been installed. Why does this kind of alarm appear?

Analysis and disposal:

1.After the cables are plugged in again.

2. If a cable is faulty, replace the cable.

3. Wrong power on sequence. The servo system should be powered first, and the controller should be powered last.

4. The axis number of the driver is set correctly or the terminal plug is not connected

2.4 [z55-ri / o not connected]

Phenomenon: the actual situation is that the system is not equipped with RI / O at all. The other situation is that the system is equipped with RI / O and the connection is completed. But why is there such an alarm?

analysis:

The power on sequence is not correct. Power on the controller first and then the Rio, resulting in the controller can not detect the Rio

Main cable CF10 (controller basic I / O) is poorly connected.

management:

1. Change the power on sequence.

2. Plug and tighten CF10 cable again.

3. Check the power supply to RI / O.

2.5 [EMG line] - emergency stop fault caused by improper connection

Analysis: it may be the fault of a connecting cable or the connection fault.

Disposal: plug in and out the cables again and tighten them. Or replace sh21 cable with r000

Cable. Generally, there are 10 wires in sh21 cable, but for C1 type driver, r000 type cable must be used. The r000 cable must be fully connected with 20 wires.

2.6 [EMG SRV] - emergency stop due to servo system fault

analysis:

1. Sh21 cable disconnection may cause the fault. The fault may also occur due to poor connection of sh21 cable.

2. If the power on sequence is not correct, the fault will also occur.

Disposal: replace sh21 cable and power on in normal order.

2.7 [EMG PLC] - emergency stop caused by PLC program

Disposal: monitor the cause of y29f = on in PLC program and remove the fault causing emergency stop.

2.8 [EMG stop] - PLC program is not running.

management:

Check whether the "ncsys" knob on the back of the controller is equal to 1 "

Set the knob to "0"

Set PLC "run" on the display.

After "format PLC memory" is executed on the communication screen of gx-d software, the PLC program is transferred in again.

2.9 [u01 -- no user PLC] - PLC program has not been input

Disposal: input PLC program.