Keyword: CNC machining parts Auto Spare Parts Milling machining Turning parts Grinding machining

Contact person: Nick Lee

Phone: (86) 15362887736

E-mail: sales03@dgmtwj.cn

Tel: (86) 769-88388276

Factory: No.2, Baidai Industrial Park, Daojiao Town, Dongguan, China ,

Caliper has many advantages such as multiple measurement modes, easy operation, durability, strong universality and low cost. It can be said that it is the most common measuring tool in the toolbox. However, there are still many matters needing attention to use the caliper correctly. Let's start with the error factors affecting the measurement results.

Error factor

When using caliper to measure, there are many factors causing errors, such as parallax, error caused by structure non-compliance with Abbe principle, thermal expansion caused by temperature difference between caliper and workpiece, etc.

In addition, because the caliper has no constant pressure device, it is difficult to grasp the suitable and uniform force during measurement, which is also another factor causing error.

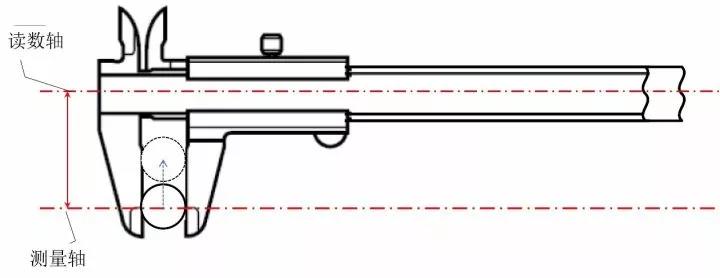

The structure of the caliper does not conform to Abbe's principle

The structure of the caliper does not conform to Abbe's principle

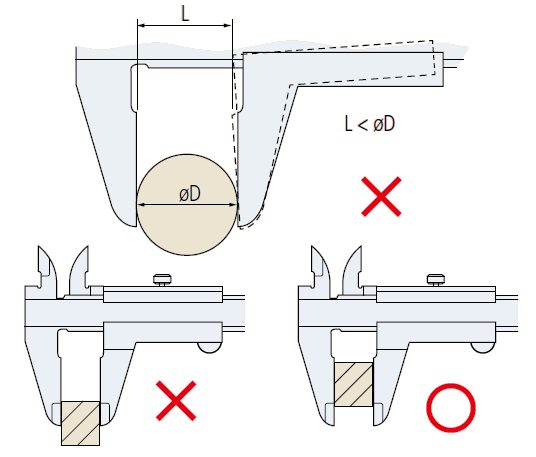

The reading axis and measuring axis of the caliper do not comply with the Abbe principle due to different axes. Therefore, when using the caliper, there is a risk of increasing the measurement error by measuring the root or tip of the measuring claw. During measurement, pay attention to the measured workpiece as close as possible to the ruler body (reading axis).

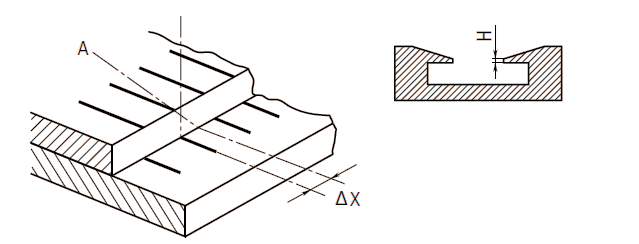

Read the parallax of the scale

When checking whether the vernier scale line is aligned with the main scale dividing line, look directly at the vernier scale line.

There is a step height difference between the vernier ruler and the scale surface of the main ruler, which is easy to cause reading error. As shown in the figure below, if the cursor scale line is viewed from an oblique direction, the results in the figure will be generated Δ Error shown in X. In order to avoid the influence of this factor, the step height (H) specified in JIS specification shall not be greater than 0.3mm.

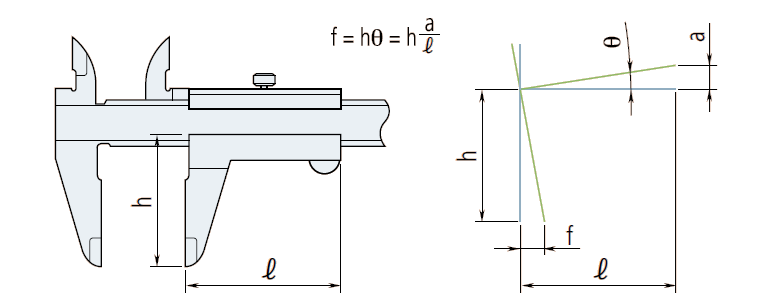

Bending of datum end face

If the ruler surface guiding the ruler sliding is bent, it will lead to the error shown in the figure below. This error can be expressed by the same calculation formula as the error that does not conform to Abbe's principle.

For example, assuming that the deformation caused by the bending of the guide ruler surface is 0.01mm/50mm and the tip of the outer diameter measuring claw is 40mm, f = 40mm × 0.01÷50=0.008mm

Relationship between measurement and temperature

The caliper body is generally made of stainless steel and has the same thermal expansion coefficient (10.2 ± 1) as iron series metals × 10-6 / K, the influence of the material of the measured object, room temperature and workpiece temperature on the measurement shall be considered.

Precautions for operation

The caliper measuring claw is very sharp, so the instrument must be operated carefully to avoid personal injury.

Avoid damaging the scale of the digital caliper, and do not engrave the identification number or leave other information with an electric pen.

Avoid colliding with hard objects or falling on the stool or floor to damage the caliper.

Maintenance of sliding surfaces and measuring surfaces

Before using the caliper, wipe off the dust and dirt on the sliding surface and measuring surface with a soft dry cloth.

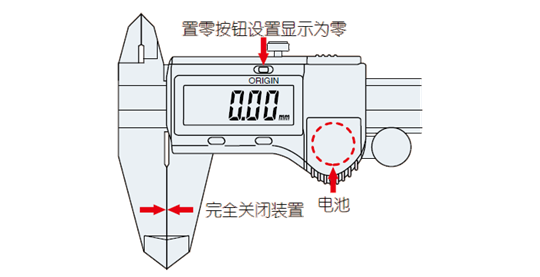

Check and calibrate the origin before use

Clamp a piece of clean paper between the outer claws and slowly pull it out. Before using the caliper, close the measuring claw and ensure that the vernier scale (or display) is set to zero. When the digital caliper is used, please reset (reset button) after replacing the battery.

Operation after use

After using the caliper, wipe off the water and oil thoroughly. Then, apply it gently with antirust oil, dry it and store it.

For waterproof caliper, in order to prevent rusting after use, it is also necessary to wipe off the moisture of the caliper.

Storage precautions

Avoid direct sunlight, high temperature, low temperature and high humidity.

If the digital caliper is not used for more than three months, remove the battery before storage.

During storage, do not completely close the external measuring claw of the caliper.