Keyword: CNC machining parts Auto Spare Parts Milling machining Turning parts Grinding machining

Contact person: Nick Lee

Phone: (86) 15362887736

E-mail: sales03@dgmtwj.cn

Tel: (86) 769-88388276

Factory: No.2, Baidai Industrial Park, Daojiao Town, Dongguan, China ,

01

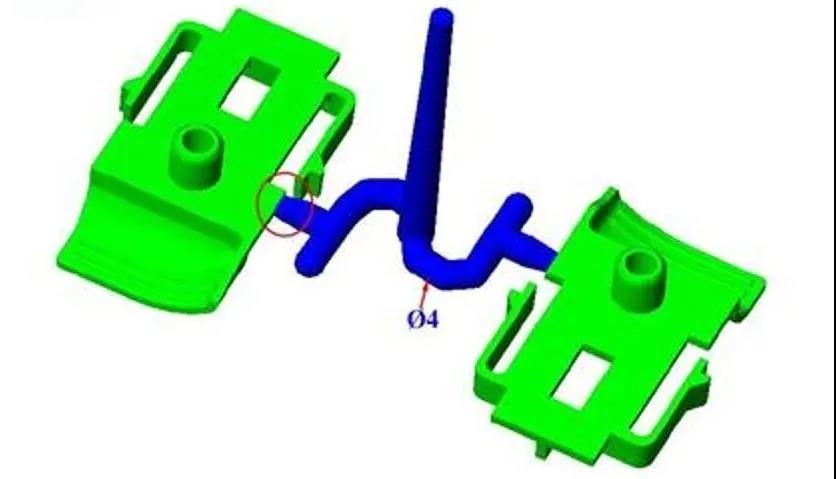

Requirements and influence of gate position

(1) Five requirements of gate location

1) Appearance requirements (gate trace, weld line)

2) Product function requirements

3) Mold processing requirements

4) Warpage of products

5) Gate capacity not easy to remove

(2) Impact on production and function

1) The injection pressure and clamping force are determined by the flow length. The shortening of the full flow length can reduce the injection pressure and clamping force.

2) The gate position will affect the packing pressure, the size of packing pressure and whether the packing pressure is balanced. Keep the gate away from the stressed position of the product (such as the bearing) to avoid residual stress. Exhaust must be considered at the gate position to avoid wind accumulation. Do not place the gate at the weak or embedded position of the product to avoid deviation.

02

Skills of gate design and location selection

(1) Gate

The gate is a short groove with small cross section area, which is used to connect the runner and the cavity. Therefore, the cross-sectional area should be small in order to achieve the following effects:

1) Soon after cavity injection, the gate is cold

2) Simple design of water outlet

3) Only a few traces are left after the nozzle is removed

4) The packing of multiple cavities can be easily controlled

5) Reduce excessive packing

(2) Gate location and size

1) Placing the gate at the thickest part of the product and pouring from the thickest part can provide better filling and pressure retaining effect. If the packing pressure is not enough, the thinner area will solidify faster than the thicker area. The gate should not be placed at the place where the thickness changes suddenly to avoid hysteresis or short shot.

2) If possible, pouring from the center of the product and placing the gate in the center of the product can provide the same flow length. The flow length will affect the required injection pressure. The central pouring can make the packing pressure in all directions uniform and avoid uneven volume shrinkage.

3) When the plastic flows into the flow channel, the plastic is close to the die surface, which is the first to reduce heat (cool) and solidify. When the plastic flows forward, only the solidified plastic layer flows through. Because the plastic is a low heat transfer material, the solid plastic can still flow to form an insulating green layer and a retaining layer. Therefore, in the ideal case, the gate should be set in the crossflow layer position to achieve the best plastic flow effect. This is most common in circular and hexagonal crossflow channels. However, trapezoidal crossflow channels cannot achieve this effect because the gate cannot be set in the middle of the channel.

(3) When determining the gate position, the following principles should be strictly observed:

1) The compound injected into each part of the cavity should be as even as possible;

2) The compound injected into the die should keep a uniform and stable flow front in each stage of the injection process;

3) It should be considered that there may be weld marks, bubbles, dimples, void position, insufficient glue injection and glue spraying;

4) The operation of the water outlet should be easy, preferably automatic;

5) The position of gate should match with all aspects.

There are no hard and fast rules for gate design methods. Most of them are based on experience, but there are two basic elements to be considered

1) The larger the cross-sectional area of the gate, the better, and the shorter the length of the channel, so as to reduce the pressure loss when the plastic passes through.

2) The gate should be thin and narrow, so as to be easy to cold and prevent excessive plastic backflow. Therefore, the gate should be in the center of the runner, and its cross section should be as circular as possible. However, the gate switch is usually determined by the module switch.

(4) Gate size

The gate size can be determined by the cross-sectional area and gate length. The following factors determine the optimum gate size:

1) Flow characteristics of rubber compound

2) Thickness of module

3) Amount of compound injected into the cavity

4) Melting temperature

5) Mold temperature

(5) Balance of gate

If a balanced runner system cannot be obtained, the following gate balancing method can be used to achieve the goal of uniform injection molding. This method is suitable for the die with a large number of cavities.

There are two ways to balance the gate: changing the length of the gate channel and changing the cross section area of the gate. In another case, when the cavity has different projection areas, the gate also needs to be balanced. At this time, to determine the size of the gate, it is necessary to first determine the size of one of the gates, find out the ratio of its corresponding cavity volume, and apply this ratio to the comparison between its gate and each corresponding cavity, then the size of each gate can be calculated successively. After the actual trial injection, the balance operation of the gate can be completed.

03

summary

The gate design is related to the size and shape of the plastic part, mold structure, injection process conditions and properties of the plastic part. But as far as the basic function is concerned, the gate section should be small and the length should be short, because only in this way can it meet the requirements of increasing the flow rate, rapid cooling and sealing, easy to separate plastic parts and minimum gate residual mark.

The key points of gate design can be summarized as follows:

1) The gate is set at the thick section of the plastic part to make the molten material flow from the thick section into the thin section to ensure complete mold filling;

2) In order to reduce the pressure loss, the gate position should be chosen to make the plastic filling process shortest;

3) The choice of gate position should be helpful to eliminate the air in the mold cavity;

4) It is not suitable for the gate to make the melt directly rush into the mold cavity, otherwise it will produce swirling flow and leave traces of swirling on the plastic parts, especially for the narrow gate;

5) The choice of gate position should prevent the seam line on the plastic surface, especially in the ring or cylindrical plastic parts, the cold material well should be opened at the molten material pouring joint of the gate surface;

6) The gate position of the injection mold with slender core should be far away from the forming core, so that the forming core will not be deformed due to material flow;

7) In order to prevent warpage, deformation and material shortage, the compound gate can be used in the forming of large or flat plastic parts;

8) The gate should be set as far as possible in the position that does not affect the appearance of plastic parts, such as the bottom of the edge;

9) The size of the gate depends on the size, shape and properties of the plastic parts;

10) When designing multi cavity injection mold, the balance of gate should be considered in combination with the balance of flow channel, so as to make the molten material fill evenly at the same time.