CNC lathe turning milling metal spare parts machining

Specification

Specification

CNC lathe turning milling metal spear parts machining

Key Specifications/Special Features:

♦ OEM/ODM Service

♦ QC inspection

♦ ISO9001 certified

♦ 25 years of experience in OEM/ODM products

Description

Description

CNC lathe turning milling metal spear parts machining

|

OEM/ODM Service |

die, molds, molding, molds, tooling CNC mahcining etc, made according to customers prints, drawings, specifications or samples |

| Production range | auto parts, industrial metal parts, machine fitting and hardware parts |

| Available materials | aluminum/zinc alloy, iron, steel alloy, plastic, brass, steel, stainless steel and plastic |

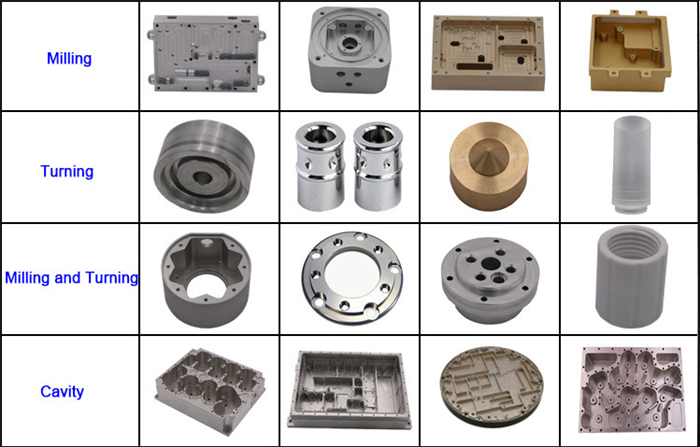

| Manufacturing process |

|

|

Available production processes |

CAD/CAM service, expert plastic injection, metal processing, finish, heat treatment, surface plating, QC testing and packing |

|

Available finishes |

fine polished, chrome, zinc plating, powder coating and painting micro-graphic and metallurgical analysis |

Equipment

Packing&Delivery

Packing Details:

Micro cnc parts aluminium cnc milling machining service

1.EPE Foam,poly bag, pp bag packaged for protecting products.

2.Standard export Carton boxes or wooden boxes.

3.We also can pack and ship according to customer's specific requirements.

Delivery Details:

3-30 days after order of Solid bicycle tire tubes

Industry

Parts-----------------------------.

Accuracy: 0.01-0.005mm

Roughness: Ra1.6-Ra3.2

Automotive

Parts--------------------------.

Accuracy: 0.01-0.001mm

Roughness: Ra0.8-Ra3.2

Tech-Communication

Parts-------------------.

Accuracy|: 0.01-0.001mm

Roughness: Ra0.8-Ra3.2

Oil

Drilling Parts--------------------------------.

Accuracy: 0.01-0.003mm

Roughness: Ra0.8-Ra3.2

General CNC Machining Process Description

Related products:

Our Service

1.Quality inspection

Pass quality system sylvac system test.

2.Gantry machining center

Passed ROHS authentication.

3.2518 CNC machining gantry center

1. What do you need to provide a quote?

Please kindly send us the drawing of your product. Details below should be included,

A.Materials B. Surface Finish C. Tolerance D. Quantity

(Please be noted that these are essential for our quoting. We couldn’t quote the specific price without any of them.)

2. How does the payment process work?

Payment terms are flexible for us in accordance with specific conditions. Generally we advise 30%TT deposit, balance be paid before shipment.

3. How do I know about the production?

We will double confirm your requirements and send you the sample before the mass production. During the mass production, we will keep you informed of any progress. Besides, we will do 100% quality inspection before shipment.

4. How do I know about the delivery?

We will inform you of the tracking number once we get it from shipping agent. Also we will keep updating the latest shipping information for you.

5. What will you do for after sales?

When our metal parts apply to your products, we will follow up and await your feedback. Any question related to our metal parts, our experienced engineers are ready to help.

We can make dies that meet exacting dimensional tolerances. Producing thousands of metal stampings at a time.

Welcome to visit us and set up long-term business relationship with us. We'll offer you our best price. And we can help you collect goods and arrange shipment.

welcome to visit our factory at any time. We promised to provide you good quality products at handsome prices, and excellent service.

Previous:Custom aluminum parts cnc machining, milling

Next:High Efficiency Custom Made CNC Milling CNC Machining Automotive Plastic Parts

BACK

BACK MT HOME

MT HOME Navbar

Navbar