Keyword: CNC machining parts Auto Spare Parts Milling machining Turning parts Grinding machining

CNC machining parts

Auto Spare Parts

Milling machining

Turning parts

Grinding machining

Plastic part

Personal care equipment

High Speed/Permanent Magnet Spindle

电动缸

Contact person: Nick Lee

Phone: (86) 15362887736

E-mail: sales03@dgmtwj.cn

Tel: (86) 769-88388276

Factory: No.2, Baidai Industrial Park, Daojiao Town, Dongguan, China ,

Advantage:

high qualification of engineer ,

high qualification staff and advantage equipment.

11 years machining experience

precision & heavy industry parts machining

precision & heavy industry parts CNC and Grinding machining

Materials

Available

Stainless

Steel

SS201, SS303,

SS304, SS316 etc.

Steel

Q235, 20#, 45#

etc.

Brass

C36000 (

C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37) , C28000(CuZn40)

Iron

1213,

12L14,1215 etc.

Bronze

C51000,

C52100, C54400, etc.

Aluminum

Al6061,

Al6063,AL7075,AL5052 etc

Terms and Conditions

Our Processing

CNC machining,

CNC milling and turning, drilling, grinding, bending,

stamping, tapping, injection

Surface

finish

Zinc-plated,

nickel-plated, chrome-plated, silver-plated, gold-plated, imitation

gold-plated,

Tolerance

0.05mm~0.1mm

QC System

100% inspection before shipment

Drawing format

CAD / PDF/ DWG/ IGS/ STEP

Packaging

Standard package / Carton

box or Pallet / As per customized specifications

Payment Terms

100%

T/T or Western Union in advance

Trade terms

EXW, FOB, CIF,

As per customer's request

1) 0-100kg: express

& air freight priority

All CNC

machining parts are custom made according to customer's drawings or samples,

no stock.

Shipment Terms

2) >100kg: sea freight priority

3) As per customized specifications

Note

If you have any CNC machining parts to be made, please feel free to send your

kind drawings/samples to us anytime by email.

|

|

. |

|||

|

Description |

Types |

|

Total Solution Provider |

· Providing one stop solution from material sourcing, product design and finished products shipment, inclusive supply chain management (ODM/OEM). |

|

Our Winning strategy |

· Providing value-added engineering service. · Assisting you from material choosing, structure testing, process, up to finished goods arrangement. · One-stop custom machining services. |

|

Application Industry |

· Automotive · Automation · Instrument Industry · Telecommunication · Optical Communication · Aerospace · Machinery Equipment · Robotics |

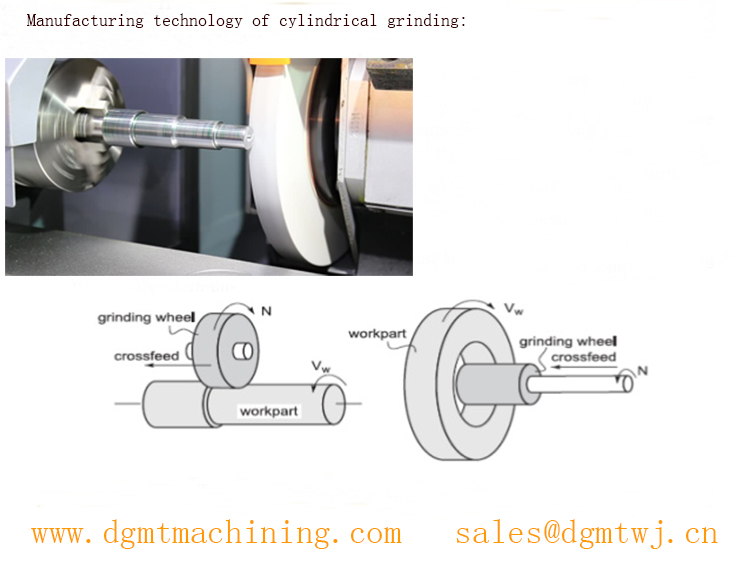

The external or internal cylindrical surface of a work piece are ground. In external cylindrical grinding. The work piece rotates and reciprocates along its axis, although for large and long work parts the grinding wheel reciprocates.

In internal cylindrical grinding, a small wheel grinds the inside diameter of the part. The work piece is held in a rotating chuck in the headstock and the wheel rotates at very high rotational speed. In this operation, the work piece rotates and the grinding wheel reciprocates.

Cylindrical grinder is similar to a plain cylindrical on except that it is more versatile. In addition to small worktable swivel, the machine provides large swivel of head stock, wheel head slide and wheel head mount on the wheel head slide