Keyword: CNC machining parts Auto Spare Parts Milling machining Turning parts Grinding machining

Contact person: Nick Lee

Phone: (86) 15362887736

E-mail: sales03@dgmtwj.cn

Tel: (86) 769-88388276

Factory: No.2, Baidai Industrial Park, Daojiao Town, Dongguan, China ,

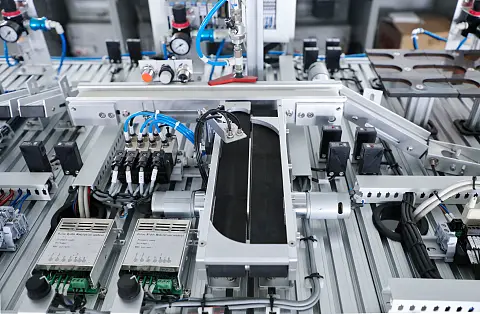

Non -standard automation machinery and equipment are also common equipment in the field of automation, but their application scenarios are relatively simple and are only developed for a specific application.

Therefore, such equipment is more difficult to design than standard automation equipment. To do a good job of non -standard automated machinery, the following points must be achieved.

01

★ It is necessary to clarify the purpose of non -standard automated mechanical design ★

improve product quality;

Improve efficiency;

Ensure production safety.

02

★ Non -standard automation mechanical design Equipment information ★

1. The necessary design manuals can be downloaded online. The manual is your best teacher. You can find the knowledge you want from the book. For example, when designing gears, you can find the parameters of designing gears in the manual. Find a manual first when you encounter a problem.

2. Download some mechanical equipment atlas or moving pictures to open your horizons.

3. The trajectory of the equipment movement is nothing more than a straight line or rotating these mechanical principles. Based on electrical pneumatic hydraulic pressure, non -standard equipment can be designed.

4. It is best to download some CAD standard parts, put it in the CAD design center, easy to paste and use, and improve work efficiency.

03

★ The preparation of non -standard automated mechanical design ★

1. Understand the use of equipment, that is, processing equipment? Or the test equipment? Or workmaking fixture.

Processing equipment: First, to ensure the accuracy of processing, the other is the convenient and accurate and fast loading, unloading.

Test equipment: Provide corresponding power supply, test the necessary test points, how to combine with electricity, display data, and read data.

Working fixture: How to limit freedom, quickly and reliable loading and unloading.

2. On -site investigation and understanding related data:

Equipment -related data, such as cash diagrams and sizes corresponding to the size.

3. Whether the relevant data of the equipment installation site interfere with other devices.

4. How much voltage is the voltage and how much power can be provided by the electrical data used by the device.

5. Check the industry standards, online manufacturers and products related data. Each manufacturer will provide principles, installation dimensions and other data to prepare for drawing.

6. Quickly formulate a plan for customers based on the preparation of the previous preparations (understanding the use of equipment, on -site inspections, and viewing industry standards). (Note that the speed of formulating the plan can reflect the strength of our company, which is important).

7. Take out the plan and report:

The feasibility report of the scheme includes the following content:

The efficiency and accuracy of the original equipment, etc., explain why it is updated or increased.

Production costs, including external processing costs of labor costs.

Cost recycling period, recover investment within half a year, do it right away; you can recover investment within one year. Including how much labor costs, the value of efficiency creation, etc.

04

★ Design ★

1. Exccrsees design in your mind, exert imagination, divide the equipment into several pieces, how each block is constructed and connected.

2. Draw and put your thoughts into the painting. Draw the main picture first, then draw the part. Easy to change design and ideas.

3. Strong school nuclear, those who have experience can be selected directly. Those who have less experience should make simple school checks to prevent major mistakes.

4. View the drawings, mainly to see if parts are interference, whether the installation is convenient, easy to use, and convenient maintenance.

5. Sort out the drawings and calculate the weight of the parts for fast quotation.

Through the browsing of the above article, we know that there are still many jobs to do the design of non -standard automation machinery. However, with the improvement of work ability and experience, I believe that you will be more and more handy in the process of design and development, designing better non -standard automated machinery equipment.

05

★ How to improve the innovative design ability of non -standard automation equipment? ★

The main purpose of the design and production of non -standard automation equipment is to meet the production needs of the production department that cannot use standard automation equipment, improve the production efficiency and product quality of these production departments, and improve the production safety of these production departments.

Compared with ordinary mechanical automation equipment, in actual production applications, non -standard automation equipment has the characteristics of low processing waste in the low processing of parts. Non -standard automation equipment is used in machine tool processing, and it also has the characteristics of low production efficiency. So what do you need to improve in improving the innovative design ability of non -standard automation equipment?

There is a way to think, there is a way to do things, one by one and the Twelve Dharma

1. Improve the professional level of non -standard automated equipment designers

Non -standard automation equipment is designed and manufactured according to the production needs of enterprise, which is a customized production equipment; that is, in the mechanical equipment market, when the existing equipment does not reach the production and use of enterprises, the corresponding equipment is needed. Non -standard automation equipment does not have standard templates and needs to be independently designed according to the characteristics of production and product. Therefore, when designing non -standard automation equipment, the professional level of designers is very important.

Improving the professional level of designers can not only improve the satisfaction of the enterprise, but also improve the quality of the equipment. The designer designed and optimized the details of non -standard automation equipment based on his work experience and professional knowledge, and followed up throughout the design process to avoid negligence during the design process, which will affect the use efficiency of non -standard automation equipment.

2. The modular design of non -standard automation equipment

The use of building block design methods can reduce the design workload of non -standard automated equipment, improve the reliability of equipment, and reduce the manufacturing cost of the equipment. Using SolidWorks to design non -standard automation devices can shorten the design cycle and reduce the difficulty of design work. If the enterprise is not satisfied with the equipment design or has a design error, Solidworks technology is also easy to repair and change the map.

When designing non -standard automated equipment, it is often reused to use screws and other components. By using Solidworks to establish parts libraries, these parts can be accessed directly to improve the efficiency of design work. The use of Solidworks can also facilitate the storage of design drawings, and complete the output of drawings and effects of various perspectives and effects. Of course, CREO can also use software such as/UG/CATIA. I think SW is easier to get started!

3. Improve and optimize materials used in non -standard automated equipment design

In order to ensure the function of the equipment, in the design of non -standard automation equipment, pay attention to improving the balance and coordination of the equipment. In the design, high -quality materials should be selected to avoid the effect of wooden barrels. In addition, the design of non -standard automation equipment must also be considered for material costs.

First of all, you must choose important parts that can ensure the normal operation of the equipment in the predetermined service life. Some parts must ensure the daily production and use of the equipment within the allowable range. Common standardized parts on top improve the generality of non -standard automation equipment.

When selecting parts, consider the vibration, impact, high temperature, low temperature, high speed, and high load performance of parts. In the case of conditions permit, strive to improve the production technology of parts, save the processing costs of parts, make the actual use of non -standard automated equipment more economical and practical, save the production costs of enterprises, and then improve the economic benefits of enterprises.

Structural optimization design and innovative design method of changing the element method

4. Improve the durability and operability of design

The design of non -standard automation equipment should be close to production needs, take into account the use and operation habits of enterprise workers, and improve the acceptance, durability and operability of non -standard automated equipment.

A good design needs to continue to use and maintain it. Therefore, when designing non -standard automation equipment, pay attention to the actual use effect of the equipment and some possible operating problems. Broadening design ideas can enhance the interaction between users and equipment with easy -to -understand and easy -to -operate operation interface, avoiding the embarrassing situation of being eliminated by the enterprise after the equipment design. Employees in the enterprise can quickly accept and the use of non -standard automated equipment can be improved. Enterprise production efficiency.

In addition, the designer must also write a detailed device manual to help enterprise workers quickly be familiar with the operating process of the equipment according to the equipment manual.

5. The design ideas of integrated equipment

When the designer completes the preliminary draft of non -standard automated equipment design of the enterprise, the designer needs to optimize the design draft, optimize the function of existing equipment and other additional functions, and consider the application requirements of the equipment to make It is more advantageous in equipment applications, and then enhances the universality, reliability, and safety of the actual production and application of the equipment in the machinery industry, and fully meets the requirements of enterprises' requirements for non -standard automation equipment.