Keyword: CNC machining parts Auto Spare Parts Milling machining Turning parts Grinding machining

Contact person: Nick Lee

Phone: (86) 15362887736

E-mail: sales03@dgmtwj.cn

Tel: (86) 769-88388276

Factory: No.2, Baidai Industrial Park, Daojiao Town, Dongguan, China ,

Calculation of bearing heating

There will be a certain difference between the temperature of the bearing during operation and the cold temperature, that is, there will be a certain temperature rise when the bearing is running. The reasons for the bearing temperature rise mainly include two aspects:

First, the external transmission. The temperature of each component of the entire machine increases due to the heat generated by the external mechanical components during operation. This heat is transferred to the bearing through conduction, thereby causing the bearing to heat up. For motors and gearboxes, the main ones are:

1) For the motor, when the motor is running, its biggest heat source is the winding and the iron core itself. It is often said that the copper loss when the motor is running is the heating loss caused by the current flowing through the wire; the iron loss is the heating of the iron core itself caused by the change of the magnetic field when the motor is running. These two parts are the main sources of motor heat, and this heat will be transmitted to the bearing through the base, shaft, and end cover, causing the temperature of the bearing to rise.

2) For the gearbox, the meshing of the gears will bring about frictional heat, which is conducted through the gears, shafts, and bases; the agitation of the lubricating oil is transmitted to the bearing, which will also cause the bearing temperature to rise.

Second, the heating of the bearing itself. When the bearing is running, there are corresponding frictions such as rolling friction, sliding friction, drag loss, and sealing friction inside the bearing. These frictions are dissipated in the form of heat, causing the temperature of the bearing itself to rise.

Equipment engineers are very concerned about the temperature of the bearing itself, so sometimes it is necessary to estimate the temperature of the bearing. This article selects a simple method for this problem to introduce to you.

Before performing specific calculations, first of all, the heating state of the above two parts can be roughly estimated. The reason for doing this kind of estimation is that if the specific calculation cannot be carried out on the spot, at least one can have a general assessment and understanding of the overall causes of the bearing heating, so as to identify whether the on-site state is normal or not.

We know that for rolling bearings, most of the friction inside the bearing is rolling friction, and the nature of rolling friction determines that rolling friction should be a small value.

Note that this is determined by the characteristics of rolling bearings, otherwise why should rolling bearings be used? Don't forget that the purpose of rolling bearings is to reduce friction and reduce drag torque.

The proportion of sliding friction inside the rolling bearing should be small, otherwise it cannot be called a rolling bearing. At the same time, the loss of rolling bearing stirring lubrication should not be a large value compared with other friction ratios. In this way, the movement of the rolling bearing is its own heat generation, not the main body of heat generation. It should be a secondary factor for the temperature rise of the entire bearing.

The main factor that causes the bearing to have a significant temperature rise is the heating of the equipment itself. The heat generated by the equipment itself will be estimated when the equipment is designed. Such heat will be conducted to the bearings. Considering factors such as heat dissipation, it will usually be less than or equal to the total amount of heat generated by the equipment itself.

Based on the above knowledge, when faced with bearing heating, first check the bearing temperature distribution of the equipment heating, and then consider the heating factor of the bearing itself. If the bearing temperature is significantly higher than the equipment temperature, vigilance should be aroused, because at this time the heating of the bearing becomes the main heat source, indicating that the internal friction state is no longer normal.

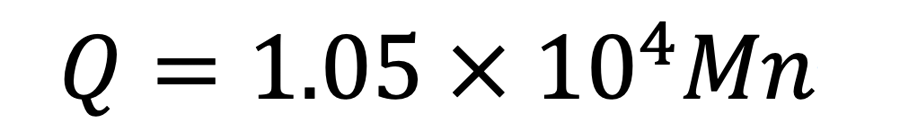

The calculation of the heating of the bearing itself starts from the calculation of the friction of the bearing. The previous article of this official account introduced the calculation method of the friction torque of the bearing itself. Usually, the heating of the bearing itself can be calculated by the friction torque of the bearing itself. The formula is as follows:

In the formula (correction: the formula should be -4):

M: the total friction torque of the bearing, refer to the calculation method introduced in the previous chapter, Calculation of Friction Torque of Rolling Bearings;

n: Bearing speed.

Interested engineers can calculate the proportion of the heating of the bearing to the heating of the entire equipment according to the heating of their own equipment. It is helpful to qualitatively and quantitatively understand the two levels of bearing heating.

Welcome to visit our Store in Alibaba:https://dgmtwj.en.alibaba.com/?spm=a2700.7756200.0.0.545871d2iSD6hl