Keyword: CNC machining parts Auto Spare Parts Milling machining Turning parts Grinding machining

Contact person: Nick Lee

Phone: (86) 15362887736

E-mail: sales03@dgmtwj.cn

Tel: (86) 769-88388276

Factory: No.2, Baidai Industrial Park, Daojiao Town, Dongguan, China ,

Bearing installation should be carried out in a dry and dust-free area as far as possible, and should be far away from equipment that generates metal chips and dust. When it must be installed in a complex environment, pollution should be minimized.

Cylindrical bearing installation

Cold install

When installing a small bearing that does not fit too tightly, you can use a sleeve (Figure 5, Figure 6) and hammer the sleeve gently to install the bearing to a suitable position. When knocking, it should act on the bearing ring as evenly as possible to prevent the bearing from tilting or skewing.

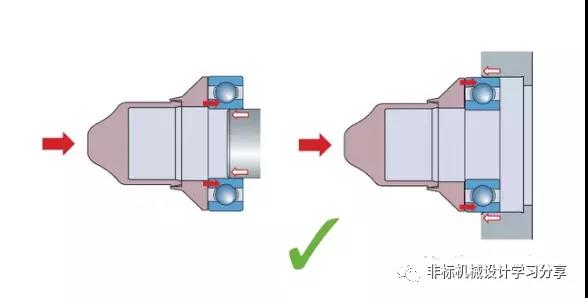

Most bearings are installed using the press-in method. If the inner and outer rings of the bearing are to be installed on the shaft and the bearing seat at the same time, it must be ensured that the same pressure acts on the inner and outer rings at the same time, and the contact surface with the installation tool must be on the same plane.

Hot install

Under normal circumstances, it is impossible to install larger bearings without heating the bearing or bearing seat, because as the size increases, the greater the force required for installation. The temperature difference between the bearing ring and the shaft or bearing seat required for hot installation mainly depends on the amount of interference and the diameter of the bearing fitting. The heating temperature of open bearings shall not exceed 120°C. It is not recommended to heat bearings with seals and dust caps above 80°C (make sure that the temperature does not exceed the allowable temperature of the seals and grease).

Tapered bearing installation

For bearings with tapered bores, most of their inner rings are installed in an interference fit. The amount of interference is determined by the axial advancing distance of the inner ring on the conical shaft diameter, adapter sleeve or withdrawal sleeve. The greater the advancing distance on the conical mating surface, the smaller the radial internal clearance of the bearing. The amount of interference can be determined by measuring the reduction in clearance or the axial advancing distance.

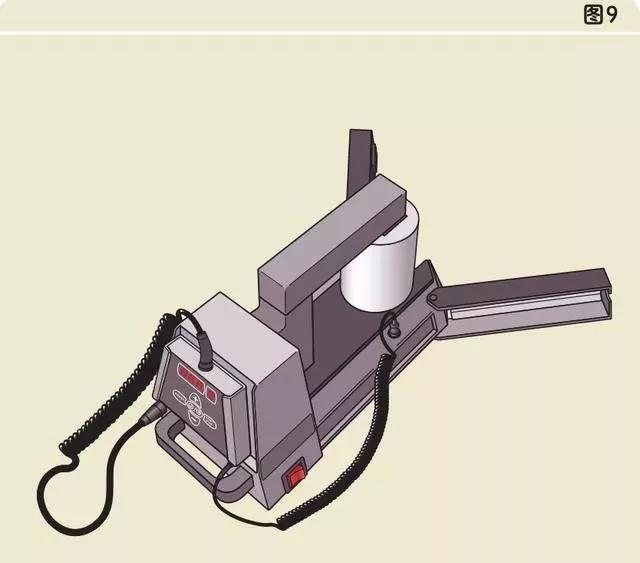

Small and medium-sized bearings can use bearing installation tools or preferably lock nuts to push the inner ring to the appropriate position on the conical shaft diameter. In the case of an adapter sleeve, use a sleeve nut that can be locked with a hook wrench or an impact wrench. For the withdrawal sleeve, a bearing installation tool or an end plate can be used to push it into the inner hole of the bearing.

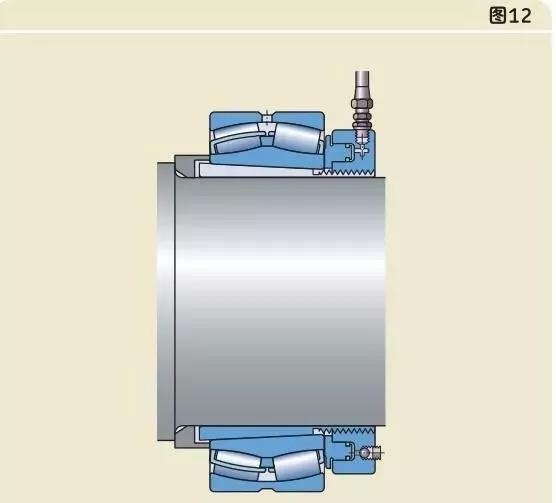

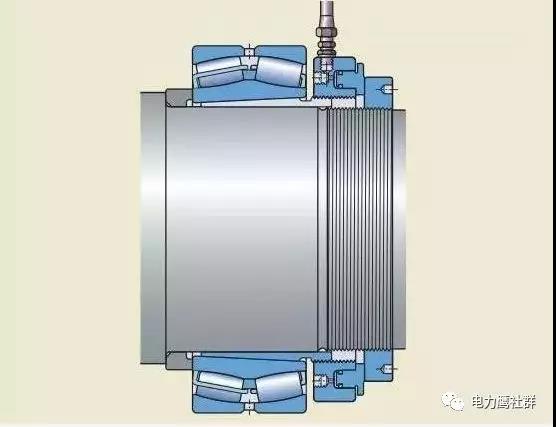

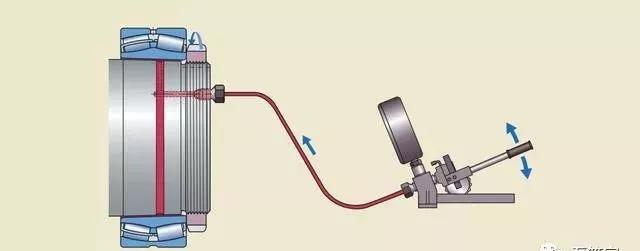

Larger bearings require more force to install, so hydraulic nuts should be used. The hydraulic nut can install the tapered bore bearing on the tapered shaft diameter (Figure 11), on the adapter sleeve (Figure 12), and on the withdrawal sleeve (Figure 13).

Oil injection

The working principle of the oil injection method is: the hydraulic oil passes through the oil hole and the oil groove under high pressure, and is injected into the mating surface between the bearing and the shaft diameter to form an oil film. The oil film separates the mating surfaces, which greatly reduces the friction between the mating surfaces. This method is usually used when the bearing is directly mounted on the conical shaft diameter. The necessary oil holes and grooves should be part of the integral shaft design. If the adapter sleeve and withdrawal sleeve have been machined with oil holes and oil grooves, this method can also be used to install the bearing on the adapter sleeve or withdrawal sleeve.

Demonstration of common errors in bearing installation

Walk the inner circle

The shaft and the inner hole of the bearing fit too loosely (commonly known as "walking the inner ring")

Because the selected fit between the shaft and the inner hole is too loose, slippage occurs between the shaft and the surface of the inner hole. Sliding friction will cause heat, which will damage the bearing due to heat.

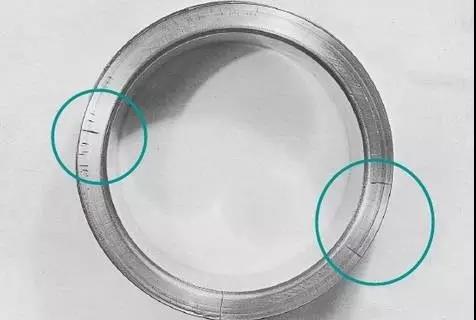

The inner ring end face and the shaft shoulder friction and heat generating cracks

When "walking the inner ring", the sliding friction between the inner ring and the shaft will generate high temperature. Because the contact surface between the end face of the inner ring and the shaft shoulder is small, the temperature will be higher. Hot cracks are generated on the end face of the inner ring, and the continuous extension of the hot cracks will cause the inner ring of the bearing to break during use.

Because "walking the inner ring" produces sliding friction between the inner hole and the shaft surface, the high temperature caused melts the surface metal and produces adhesion.