Keyword: CNC machining parts Auto Spare Parts Milling machining Turning parts Grinding machining

Contact person: Nick Lee

Phone: (86) 15362887736

E-mail: sales03@dgmtwj.cn

Tel: (86) 769-88388276

Factory: No.2, Baidai Industrial Park, Daojiao Town, Dongguan, China ,

On April 12, 2021 China International Machine Tool Exhibition (CIMT) was launched, Gree showcased 4 core technology machine tools and core parts of machine tools.

China International Machine Tool Show is the most prestigious machine tool exhibition in China and one of the four major machine tool exhibitions in the world. At the exhibition, Gree CNC machine tools competed with all kinds of advanced machine tools around the world, showing the latest achievements of Gree equipment manufacturing technology.

In the Gree booth, a machine tool occupying about one-fifth of the booth space made the scene stop and visit. Gree staff introduced that this is Gree Longmen Machining Center GA-GF2517, which is widely used in the processing of molds, castings, medium and large plates and parts. "For example, the large-scale integral structural parts widely used in modern automobiles have complex shapes, large cutting capacity, and poor rigidity. They need to be processed on modern CNC milling machines with large worktables and multiple high-speed milling heads. We Gree The gantry machining center meets these characteristics. Its base, door and bridge are integrally formed castings, with a load-bearing capacity of 8T, and a gearbox with full gear transmission, which can realize high-torque cutting."

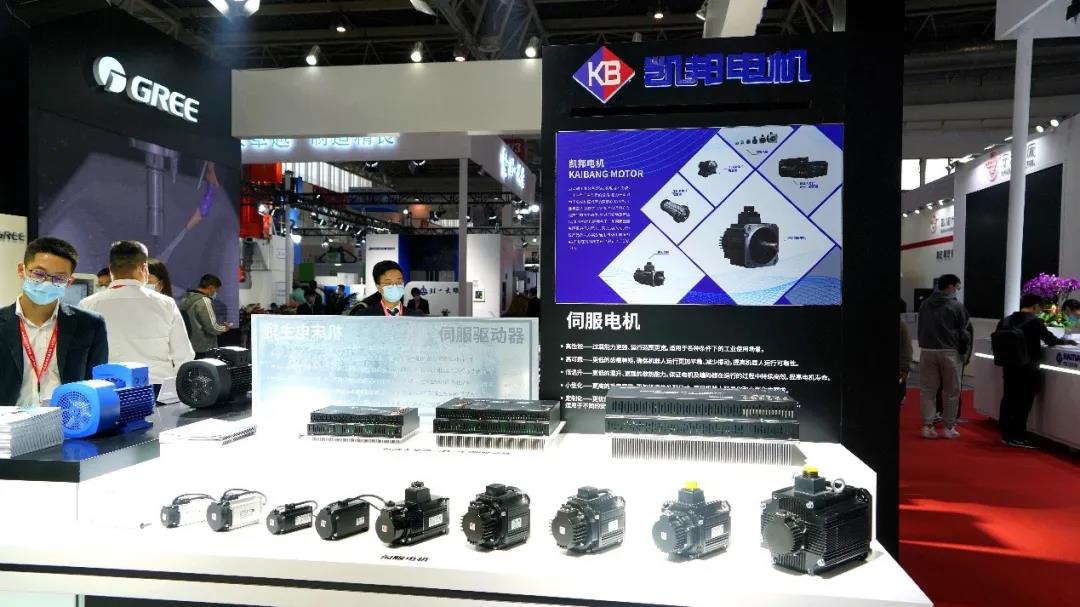

On the other side of this gantry machining center, there are many "exquisite" parts displayed, which are the core parts of the machine tool, including servo motors, drives, spindle motors, etc. Gree technicians on site emphasized that these core components have experienced "a leap from exploration to mastering international leading technology."

In addition to the extreme contrast between "large" machine tools and "small" parts, the multiple Gree machine tools that were "show-operated" on site also gave visitors the opportunity to "review on site".

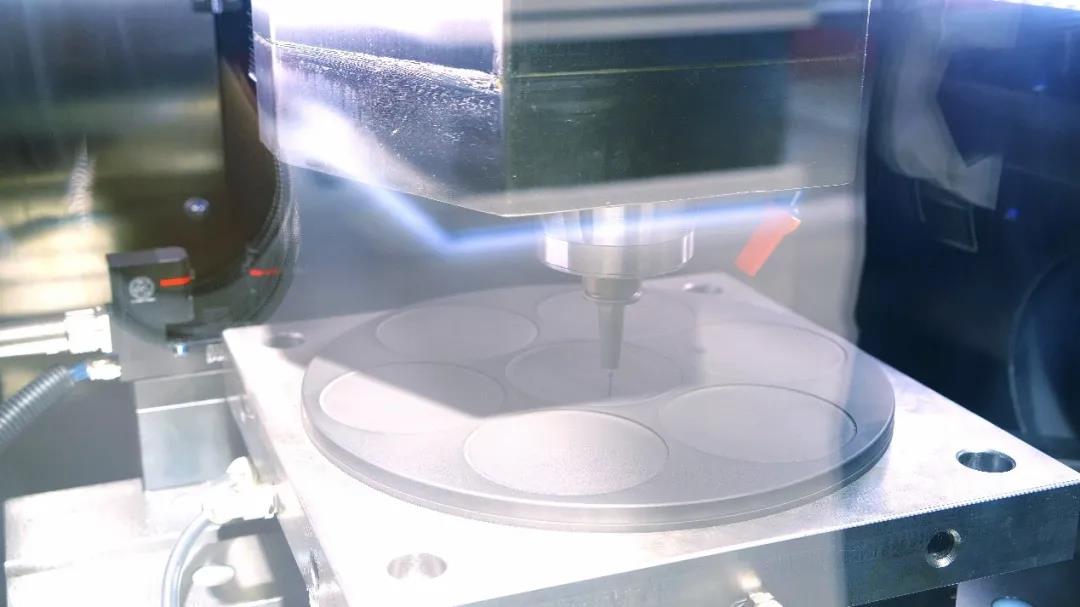

"This machine tool is making a MOCVD epitaxial graphite base, which is used in the semiconductor processing industry." The instructor introduced in front of the Gree semiconductor base processing center GA-DV450: "Gree semiconductor base processing center GA-DV450 adopts a 40-bit circle Disk-type tool magazine, linear motor drive and closed-loop control of grating ruler, fast traverse speed up to 60m/min."

Under the development trend of high-speed, high-precision, and high-efficiency CNC machine tools, Gree has conducted research on core key technologies such as high-speed electric spindles, linear servo motors and drives, and CNC systems of CNC machine tools. In 2019, Gree broke through the "high-performance linear servo motor and drive technology", outstanding performance in technical innovation, practicality and other aspects, and has reached the "international leading" level after identification.

Careful observation is not difficult to find that every machine tool exhibited this time is equipped with an "air conditioner", which is a precision inverter cooler independently developed by Gree, which is used to "prevent heatstroke and cool down" the machine tool.

Numerical control machine tools will generate a lot of heat during operation. If they are not cooled in time, it will cause serious harm to equipment and products. Gree's self-developed precision frequency conversion cooling unit provides cold water or cold oil for CNC machine tools, which can quickly adjust the temperature of the coolant to a balanced state, so that the equipment can reach the best operating state.

In addition, from the main body of the machine tool, to the core components, and then to the precision frequency conversion cooler matched with the machine tool, Gree has carried out a comprehensive layout of the "industrial mother machine" CNC machine tool from point to surface. Gree technicians reminded the audience: "The boundaries of imagination can be widened."

With the CNC machine tool as the "center", Gree drew concentric circles named "core technology" on the automated flexible production line-industrial robots serve multiple machining centers and operate in an orderly manner; each of the entire line's operating status Item data can all be presented on the online digital information platform to realize networked, digitalized, intelligent, and informationized control and management.

Deeply cultivating the "three system platforms", "four product chains", and "a full-industry chain system solution", Gree conducts the whole process of program design, research and development, production, installation and commissioning, and acceptance, and finally provides customers with a full range of services Smart factory solutions.

The person in charge of the relevant technology at the site introduced: "Our solution is not only applied to precision mold processing for home appliances, but also serves customers in other industries, such as high-precision mold processing in the automotive, 3C and other fields."

Gree recently provided a company with an overall solution for auto parts manufacturing, including CNC machine tools and welding robots, to help upgrade its intelligent manufacturing. Among them, the CNC machine tool solutions include vertical and multi-face machining CNC machine tools, with high-speed multi-face milling, boring, drilling, tapping parts processing capabilities, according to different procedures, through the programming software to upload the program to the machine tool, after the workpiece is clamped, the machine tool The digital control system reads and recognizes the program, automatically selects and replaces tools, and automatically completes processing. At present, the automatic solution has achieved batch production and is in good use.

Dong Mingzhu once said in an interview: "In the field of industrial equipment, we have achieved little results and initial results." The "small results" in her mouth are the independent development of various CNC machine tools and cooperation with major domestic and foreign brands. "Break your wrists"; 8 years of deep cultivation, completed the full production process coverage of parts casting, CNC machine tool finishing, and automated production lines.

More important is the "big determination" behind the "small results". Dong Mingzhu said that this year Gree will further accelerate the ability to master core technologies and accelerate the transformation of innovative results; at the same time, it will also increase research on key core technologies such as smart equipment. , And more in-depth research on key components of electronic products such as motors and capacitors.