Keyword: CNC machining parts Auto Spare Parts Milling machining Turning parts Grinding machining

Contact person: Nick Lee

Phone: (86) 15362887736

E-mail: sales03@dgmtwj.cn

Tel: (86) 769-88388276

Factory: No.2, Baidai Industrial Park, Daojiao Town, Dongguan, China ,

100 mm thick steel,

Use slow walking silk to cut one and trim two,

What kind of surface roughness can be achieved?

Based on the technical level of the industry's mainstream slow moving machine tools, it is generally recognized that the surface roughness of cutting one and trimming two is about Ra0.8 μ m, not to mention the thickness of 100 mm.

As a pioneer of manufacturing technology, Muye has a long history of wire cutting research and development, and its technology has always been in the forefront of the world. The U series of domestic slow moving machine tools introduced by Muye company adopt a series of latest technologies, and the processing performance has been improved revolutionarily.

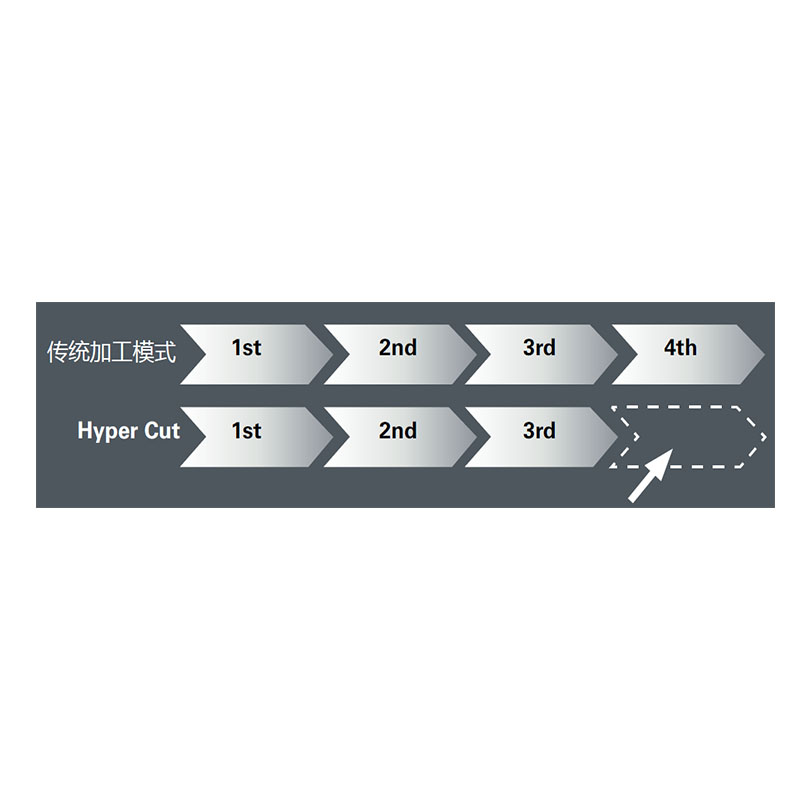

The surface roughness of Ra0.4 μ M can be achieved by the ultra cutting technology of Muye U series slow moving machine tool under standard processing conditions. Compared with the traditional processing mode, it can achieve excellent surface roughness and reduce the number of tool trimming, use less lines and process faster.

The surface roughness of Ra0.4 μ M can be achieved by the ultra cutting technology of Muye U series slow moving machine tool under standard processing conditions. Compared with the traditional processing mode, it can achieve excellent surface roughness and reduce the number of tool trimming, use less lines and process faster.

1) The steel can reach Ra0.4 μ m after cutting and trimming

2) The hard alloy can reach ra0.34 μ m after cutting and trimming

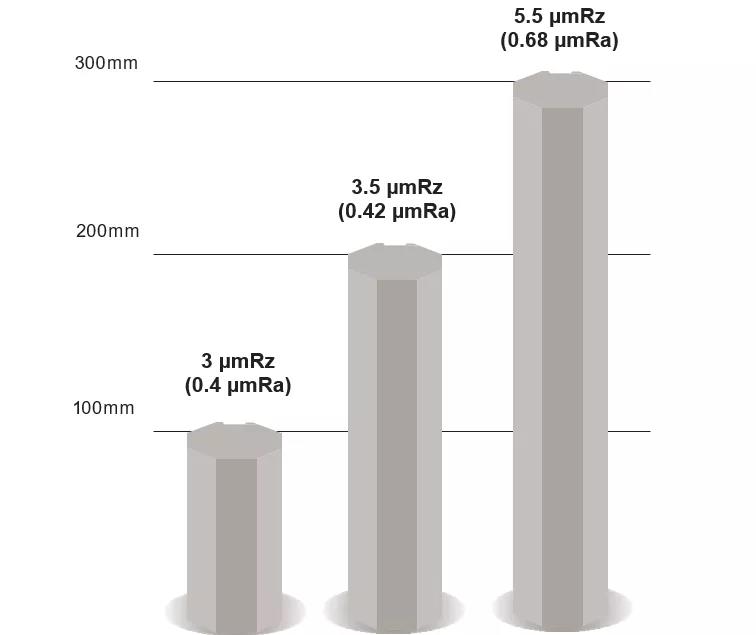

3) Even if the workpiece is high, it still has good surface roughness

Workpiece material: SKD11 steel

Wire diameter: Φ 0.25mm brass wire

Material thickness: 80mm

Surface roughness: rz3 μ m (Ra0.4 μ m)

At the same time, Muye's unique GS cut technology can ensure the straightness of thicker workpieces, and only one tool can achieve a tolerance of 5 μ m for workpieces larger than 300 mm. This technology can cut a more straight and accurate workpiece in rough machining, which can remove less material from the workpiece in finish machining and obtain higher accuracy.

U series slow wire machine has the following main features:

1) Mechanical structure with high rigidity and stability

Laminated mechanical structure, each shaft element does not interfere with each other; the worktable is fixed, and the shaft movement is not affected by the weight of the workpiece; the ball screw is supported at both ends to ensure the stability of the transmission.

2) Independent control of upper and lower processing fluid

Up and down processing fluid is supplied by different pumps; up and down flushing, flow, pressure independent control; digital control of water flow; excellent control of processing hydraulic pressure, good shape accuracy.

3) Pre guidance technology

The upper and lower guides ensure the vertical position of the line, and the perpendicularity will not be affected by the loss of the conductive block; the diamond V guide support line compresses the conductive block to ensure good conductive effect.

4) H.e.a.t. Technology (high energy application technology)

Both sides away from high-speed cutting technology, good straightness and segment difference size, processing efficiency increased by 51%, cost reduced by 30%.

5) Condition database

The machine tool is equipped with processing parameters of various materials, including conventional steel parts, non-ferrous metals, superhard materials, aviation materials, semiconductor PCD, SiC and other materials.

6) Intelligent and simple hyperi controller

Flow menu setting; gesture control, good interactivity; intelligent control - Dr. E; information feedback, picture assistance; constant guidance, manual automatic connection.

7) Easy maintenance

Conductive block 10 seconds transposition; filter body and water separation; machine real-time video synchronous teaching, maintenance worry free.

Muye new generation Muye U series slow moving wire can meet the wide and harsh requirements of large and medium-sized mold manufacturing, precision mold processing shop, parts processing and other industries, and provide customers with stronger production competitiveness.