Keyword: CNC machining parts Auto Spare Parts Milling machining Turning parts Grinding machining

Contact person: Nick Lee

Phone: (86) 15362887736

E-mail: sales03@dgmtwj.cn

Tel: (86) 769-88388276

Factory: No.2, Baidai Industrial Park, Daojiao Town, Dongguan, China ,

Drilling is one of the operation skills of fitter. In the actual production and fitter skills competition, it is difficult to finish the processing and measurement of high-precision hole spacing on the common bench drill.

Only when the dimension accuracy of hole spacing reaches IT6, the interchangeability requirement after assembly can be met. After drilling, the surface roughness is ra = 6.3-12.5 μ m, RA = 3.2 μ m for common reaming, RA = 1.6 μ m for fine reaming, and RA = 0.4-1.6 μ m for reaming. Therefore, the premise of machining precise hole distance is that the hole must be expanded or reamed.

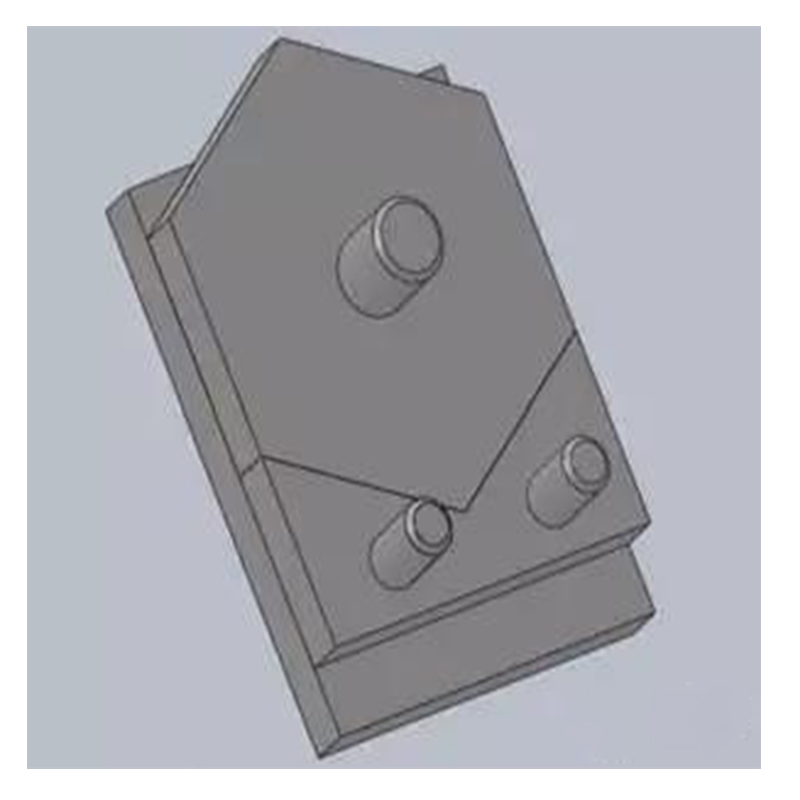

As shown in Figure 1, the V-shaped plate is required to be assembled by turning over, and the hexagonal plate is required to be assembled by 60 ° rotation for 6 times. The hole distance between the bottom plate and the V-shaped block should be 50-0.010mm, and the distribution is high. In order to meet the assembly requirements, it is required that the distance accuracy from hole to hole and from hole to edge can reach IT6. The specific processing method is introduced below.

1. Distance control between two holes

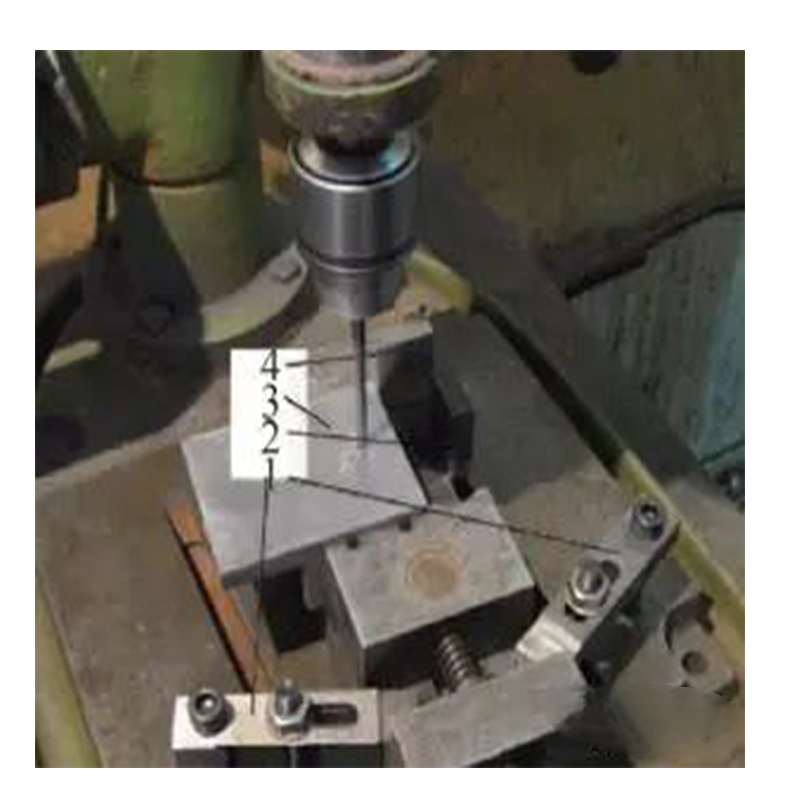

(1) Measuring rod correction drilling method (see Fig. 2). Mark out the center line of the hole on the workpiece, clamp the workpiece, drill and ream the first hole according to the line, insert a measuring rod (precision pin) into the processed hole, drill the chuck, and then clamp another measuring rod. Measure the distance between two measuring rods with a caliper or micrometer, adjust the position of the flat tongs, and then drill and ream the second hole after pressing with a pressing plate. This method has the advantages of simple auxiliary tools and high efficiency, but the probability of reaching the accuracy requirement is only about 70%.

(2) Translational Gauge Block drilling method (see Fig. 3). When clamping the workpiece, put the gauge block with the required hole distance between the workpiece and the baffle. After drilling and reaming the first hole, remove the gauge block, move the workpiece and close to the baffle, and then drill and ream the second hole. The characteristic of this method is high efficiency, and the probability of reaching the accuracy requirement is 90%.

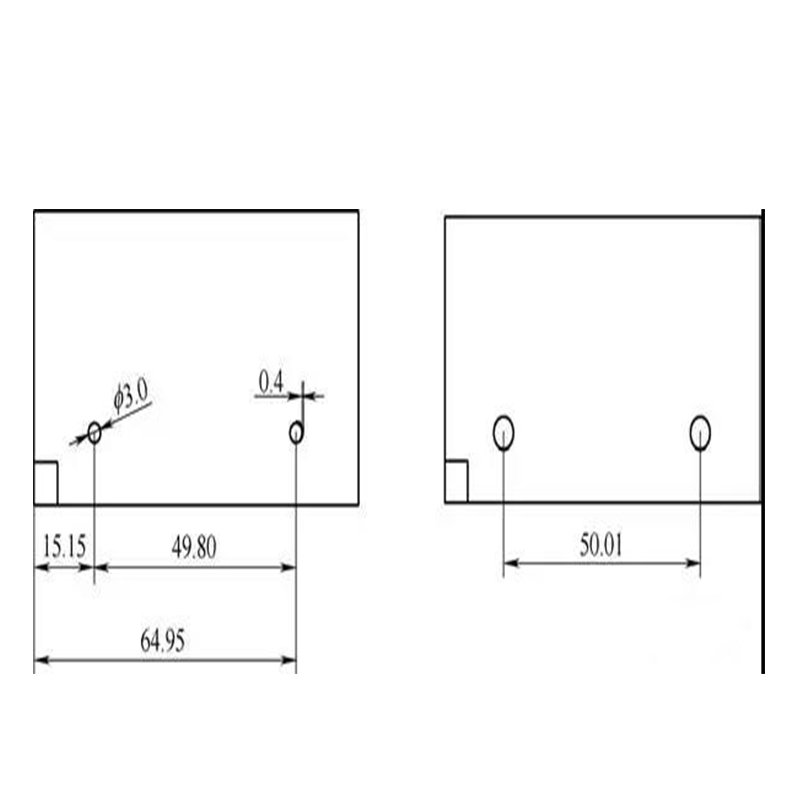

(3) Hole repair and reaming. During operation, drill a hole 2mm smaller than the required hole diameter according to the line, and measure the hole spacing, as shown in Figure 4. The actual hole spacing after measurement is 49.8mm. The actual value is less than the ideal value by 0.2mm. When one side of one hole is filed with a round file, only the outer side of the hole needs to be filed by 0.4mm to ensure that the distance between the elliptical hole and the other hole is 50mm. After reaming the two holes, measure the hole spacing again, and repeat until the hole spacing meets the requirements of 50-0.010mm. The characteristic of this method is that the probability of reaching the accuracy requirement is as high as 99%, but the efficiency is low.

2. Distance control from hole to edge

(1) The method of hole finding at the edge (taking the edge as the benchmark, ensuring the distance from the hole to the edge through hole repair). After machining the hole according to the line (2mm smaller than the required hole diameter), measure the distance from the hole to the contour. If it is within the tolerance value, the hole can be expanded and reamed. If the tolerance value is exceeded, the hole shall be repaired to ensure that the distance between the center of the ellipse hole and the shape of the workpiece is within the tolerance value, then the hole can be expanded and reamed. This method is characterized by high efficiency, but the success rate is slightly poor.

(2) The hole edge finding method (taking the hole as the benchmark, ensuring the distance from the hole to the edge by trimming). Process the hole according to the line (ensure that there is enough allowance from the hole to the edge). The distance between the hole and the workpiece contour can be ensured within the tolerance value by filing the workpiece contour. This method is characterized by low efficiency but high success rate.

3. Measurement method of hole spacing

Accurate measurement is the premise of machining high-precision hole spacing. This paper introduces several measurement methods.

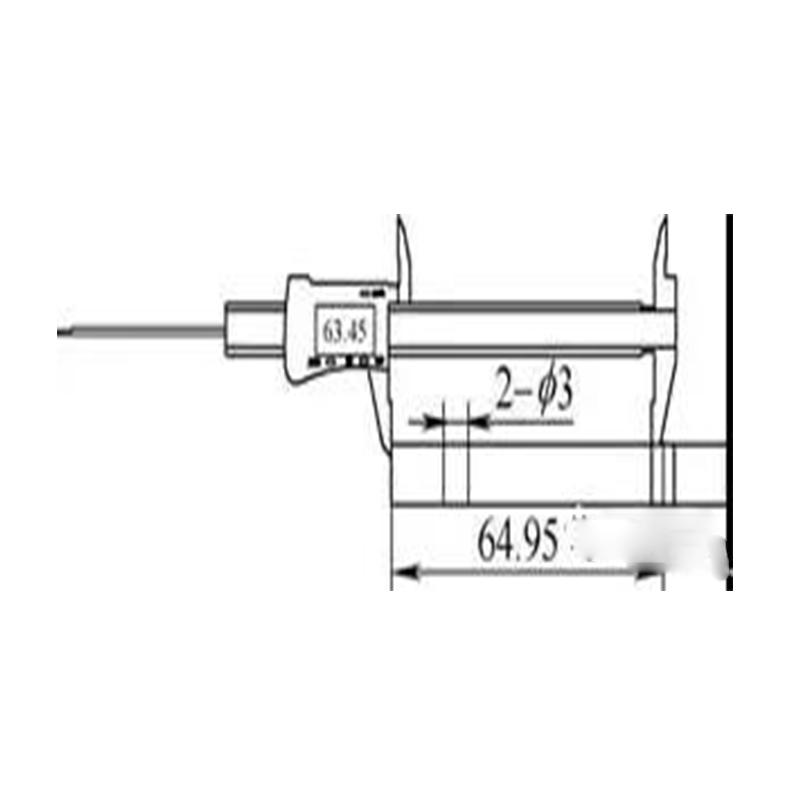

(1) Caliper same datum measurement method (see Figure 5). In order to avoid the measurement error of hole spacing caused by aperture error, the following methods can be used for measurement: two measurements are based on the left side (surface), and the subtraction of two measured values is the distance between two holes. The advantage of this method is that as long as the two holes are processed by one drill, the accurate hole spacing value can be obtained without considering the size of the hole diameter, and the measurement efficiency is high.

(2) The measuring method of gauge and gauge block (see Fig. 6). The distance between two holes and the same side (surface) is measured by the comparison method with the gauge block and the lever dial gauge. The distance between two holes is calculated by subtracting the two values. This method has high measurement accuracy, but the operation is relatively complex and the efficiency is low.

4. Conclusion

According to the accuracy requirements of the hole, processing time requirements and the existing tools, the operator should flexibly choose which processing method to use, or use several methods comprehensively. The above methods can be used as reference for fitter in actual production or skill competition.